Enalapril maleate tablet and preparation method thereof

A technology of enalapril maleate and Pulee tablets, which is applied in the direction of pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of complicated preparation process and increased cost, and achieve simple process, Cost saving and high lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

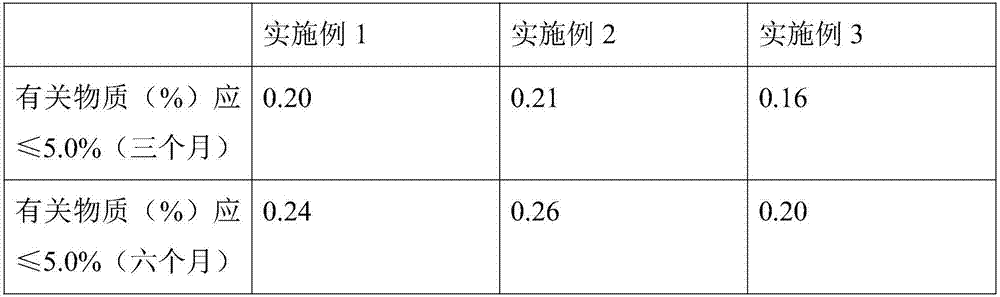

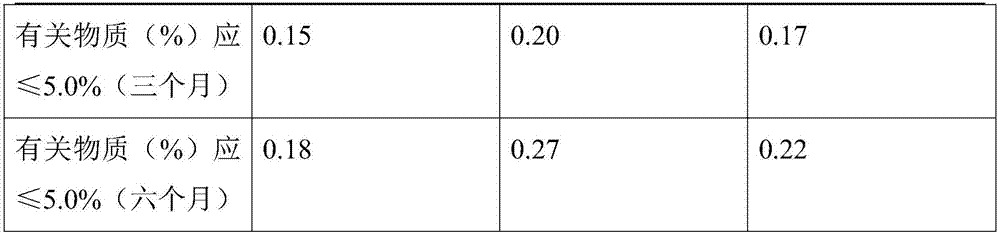

Examples

Embodiment 1

[0021] A kind of enalapril maleate tablet, according to parts by weight, comprises following raw materials:

[0022] 8 parts of enalapril maleate, 5 parts of citric acid, 55 parts of lactose, 3 parts of sodium carboxymethyl starch, 0.2 parts of polyvinylpyrrolidone and 2.8 parts of lubricant, the lubricant is composed of nano silicon dioxide and talc powder mixture.

[0023] Preparation:

[0024] 1) Enalapril maleate and lactose are mixed uniformly in equal increments, passed through a 100-mesh sieve, and set aside;

[0025] 2) mix the powder prepared by step 1) with the sodium carboxymethyl starch of the prescription amount, pass through a 100 mesh sieve, and set aside;

[0026] 3) Mix the powder prepared in step 2) with the prescribed amount of polyvinylpyrrolidone, lubricant, and citric acid, pass through a 100-mesh sieve, and dry the powder into tablets to obtain enalapril maleate tablets agent.

Embodiment 2

[0028] A kind of enalapril maleate tablet, according to parts by weight, comprises following raw materials:

[0029] 4 parts of enalapril maleate, 2 parts of citric acid, 45 parts of lactose, 5 parts of pregelatinized starch, 20 parts of croscarmellose sodium, 2.2 parts of polyvinylpyrrolidone, and 0.2 parts of lubricant, lubricated The agent is a mixture of nano silicon dioxide and talcum powder.

[0030] Preparation:

[0031] 1) Enalapril maleate, pregelatinized starch and lactose are mixed uniformly in equal increments, passed through a 100-mesh sieve, and set aside;

[0032] 2) Mix the powder prepared in step 1) with the croscarmellose sodium of the prescribed amount, pass through a 100-mesh sieve, and set aside;

[0033] 3) Mix the powder prepared in step 2) with the prescribed amount of polyvinylpyrrolidone, lubricant, and citric acid, pass through a 100-mesh sieve, and dry the powder into tablets to obtain enalapril maleate tablets agent.

Embodiment 3

[0035] A kind of enalapril maleate tablet, according to parts by weight, comprises following raw materials:

[0036] 10 parts of enalapril maleate, 8 parts of citric acid, 65 parts of lactose, 24 parts of croscarmellose sodium, 3 parts of polyvinylpyrrolidone and 3 parts of lubricant, the lubricant is nano silicon dioxide and A mixture of talcum powder.

[0037] Preparation:

[0038] 1) Enalapril maleate and lactose are mixed uniformly in equal increments, passed through a 100-mesh sieve, and set aside;

[0039] 2) Mix the powder prepared in step 1) with the croscarmellose sodium of the prescribed amount, pass through a 100-mesh sieve, and set aside;

[0040] 3) Mix the powder prepared in step 2) with the prescribed amount of polyvinylpyrrolidone, lubricant, and citric acid, pass through a 100-mesh sieve, and dry the powder into tablets to obtain enalapril maleate tablets agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com