Metal dust centralized recovery and treatment equipment

A metal dust, recycling and processing technology, applied in the direction of fixed filter element filter, the use of liquid separation agent, filtration and separation, etc., can solve the problems of single metal dust recovery method, inability to centralize metal dust treatment, incomplete recovery and other problems, to eliminate Defects in production stand-by, elimination of dust explosions, and effects of reducing oxidation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

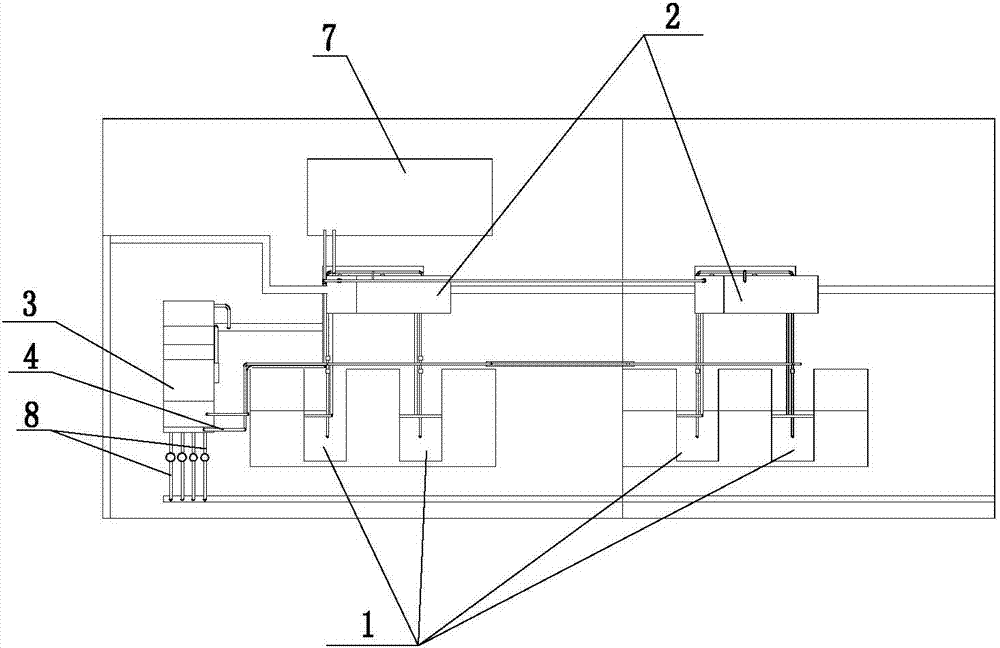

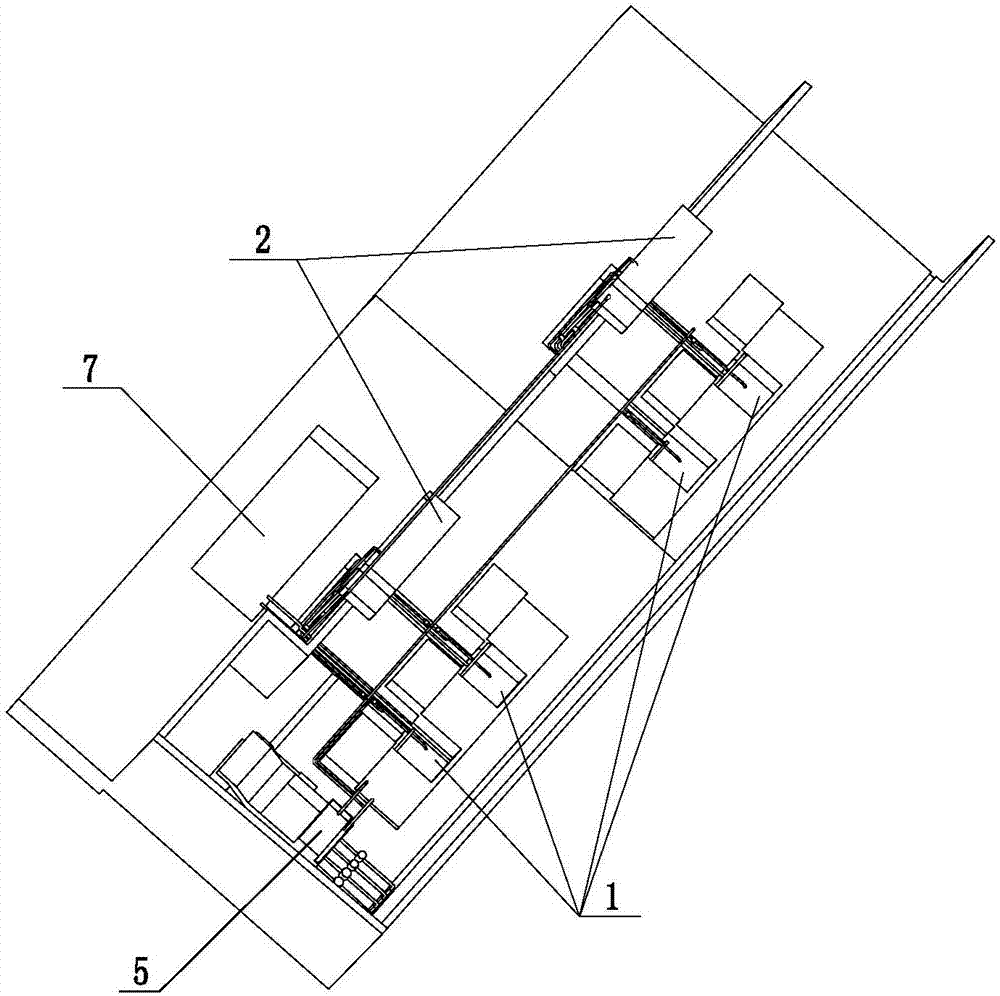

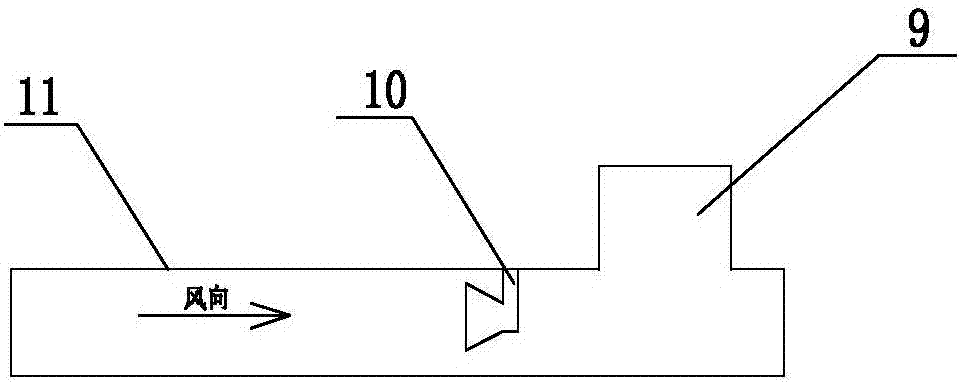

[0014] Such as Figure 1 to Figure 4 As shown, the present invention includes a plurality of recycling pools 1, reservoirs 2 and sewage filter 3, and the metal dust produced by the polishing machine is connected with the collecting pipe 11, and the inner chamber of the collecting pipe provides negative pressure through the fan 9, and the inner chamber of the collecting pipe is provided with Nozzle 10, the spraying direction of nozzle 10 is opposite to the direction of fan 9, metal dust is dissolved by water flow and flows into recovery pool 1, all waste water in recovery pool 1 is lifted by water pump respectively, passes through water pipe and passes through three-way valve to form two paths, One way flows into the reservoir 2 whose height is higher than that of the recovery pool 1, and the other way is connected to the main waste water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com