A kind of preparation method of manganese dioxide/carbon composite nanotube

A manganese dioxide and carbon composite technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of no application, etc., and achieve the effect of simple and easy method and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

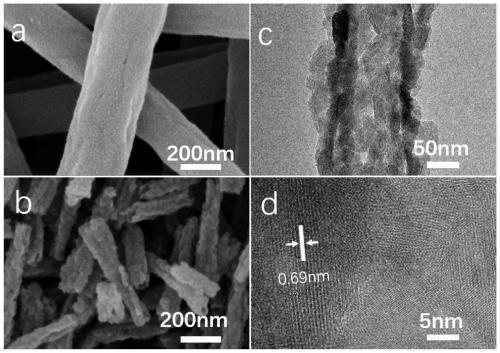

[0045] Example 1 MnO 2 / Preparation of CNTs:

[0046] 1. Electrospinning:

[0047] A solution of polyacrylonitrile (PAN) in dimethylformamide (DMF) with a concentration of 9 wt% was prepared, and then electrospinning was performed. Constant current syringe pump push speed 1mL / h, voltage 15kV, receiving distance 15cm, humidity 32%. After the electrospinning was completed, the PAN nanofiber membrane was peeled off from the aluminum foil on the receiving plate.

[0048] 2. Preoxidation:

[0049]Take a certain quality of PAN nanofiber membrane, place it in a muffle furnace and heat it in an air environment. The heating program is: from room temperature to 180°C at 2°C / min, and then to 260°C at 1°C / min , and maintained at 260° C. for 60 min, and finally cooled down to room temperature naturally to obtain pre-oxidized nanofibers.

[0050] 3. Carbonization:

[0051] Place the pre-oxidized nanofibers obtained in the previous step in a tube furnace under N 2 environment (N 2 T...

Embodiment 2

[0056] Example 2 MnO 2 / Preparation of CNTs:

[0057] 1. Electrospinning:

[0058] A solution of polyacrylonitrile (PAN) in dimethylformamide (DMF) with a concentration of 9 wt% was prepared, and then electrospinning was performed. Constant current syringe pump push speed 1mL / h, voltage 15kV, receiving distance 15cm, humidity 40%. After the electrospinning was completed, the PAN nanofiber membrane was peeled off from the aluminum foil on the receiving plate.

[0059] 2. Preoxidation:

[0060] Take a certain quality of PAN nanofiber membrane, place it in a muffle furnace and heat it in an air environment. The heating program is: from room temperature to 180°C at 2°C / min, and then to 260°C at 1°C / min , and maintained at 260° C. for 60 min, and finally cooled down to room temperature naturally to obtain pre-oxidized nanofibers.

[0061] 3. Carbonization:

[0062] Place the pre-oxidized nanofibers obtained in the previous step in a tube furnace under N 2 environment (N 2 ...

Embodiment 3

[0070] Example 3 MnO 2 / Preparation of CNTs:

[0071] 1. Electrospinning:

[0072] A solution of polyacrylonitrile (PAN) in dimethylformamide (DMF) with a concentration of 9 wt% was prepared, and then electrospinning was performed. Constant current syringe pump push speed 1mL / h, voltage 15kV, receiving distance 15cm, humidity 35%. After the electrospinning was completed, the PAN nanofiber membrane was peeled off from the aluminum foil on the receiving plate.

[0073] 2. Preoxidation:

[0074] Take a certain quality of PAN nanofiber membrane, place it in a muffle furnace and heat it in an air environment. The heating program is: from room temperature to 180°C at 2°C / min, and then to 260°C at 1°C / min , and maintained at 260° C. for 60 min, and finally cooled down to room temperature naturally to obtain pre-oxidized nanofibers.

[0075] 3. Carbonization:

[0076] The pre-oxidized nanofibers obtained in the previous step were placed in a tube furnace and heated in an Ar env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com