Preparation method of simple and environment-friendly few layer graphene

A technology of oligolayer graphite and graphite, which is applied in the field of simple and environment-friendly preparation and oligolayer graphene, can solve the problems of product inhomogeneity, difficult treatment, waste acid, etc., and achieve the effect of uniform reaction and consistent product peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of oligolayer graphene:

[0022] (1) Commercial graphite powder, hydrogen peroxide (30%), and water are stirred and mixed uniformly; in the mixed solution, the mass ratio of graphite powder and water is 1%, and the volume ratio of hydrogen peroxide and water is 10%;

[0023] (2) Put the mixed solution into the reaction kettle, and react at 180° C. for 24 hours to obtain the described oligolayer graphene aqueous solution, and obtain oligolayer graphene powder after freeze-drying;

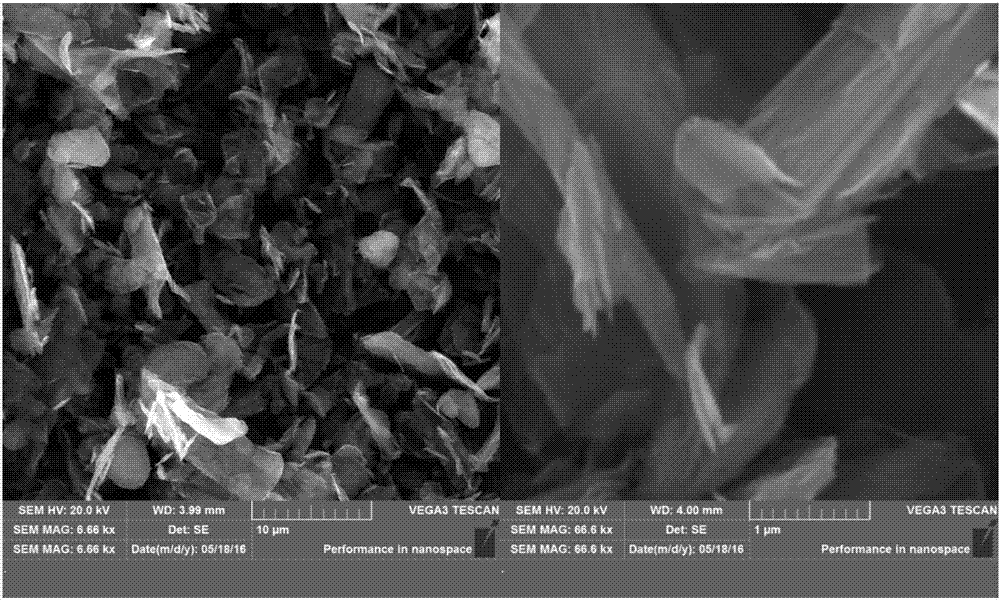

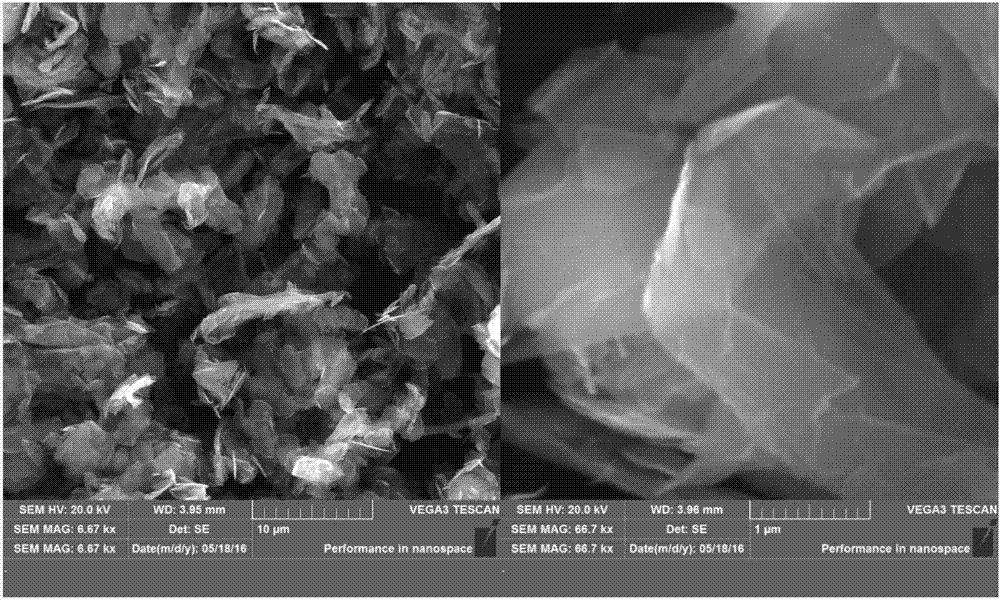

[0024] figure 1 It is an optical photograph of an aqueous solution of oligolayer graphene, and it can be seen that the resulting oligolayer graphene has good dispersion. figure 2 It is a scanning electron microscope (SEM) picture of the raw material commercial graphite powder. It can be seen that the lamellar accumulation in the commercial graphite powder is serious. image 3 It is the scanning electron microscope (SEM) picture of the oligolayer graphene prepared in Example 1, a...

Embodiment 2

[0026] Preparation of oligolayer graphene:

[0027] (1) Commercial graphite powder, hydrogen peroxide (30%), and water are stirred and mixed uniformly; in the mixed solution, the mass ratio of graphite powder and water is 1%, and the volume ratio of hydrogen peroxide and water is 1%;

[0028] (2) Put the mixed solution into the reaction kettle, and react at 180° C. for 24 hours to obtain the described oligolayer graphene aqueous solution, and obtain oligolayer graphene powder after freeze-drying;

Embodiment 3

[0030] Preparation of oligolayer graphene:

[0031] (1) Commercial graphite powder, hydrogen peroxide (30%), and water are uniformly mixed; in the mixed solution, the mass ratio of graphite powder to water is 0.1%, and the volume ratio of hydrogen peroxide to water is 10%;

[0032] (2) Put the mixed solution into the reaction kettle, and react at 180° C. for 24 hours to obtain the described oligolayer graphene aqueous solution, and obtain oligolayer graphene powder after freeze-drying;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com