Method for extracting aluminum salt and recycling waste acid from acid solution containing aluminum salt

A technology of acid solution and aluminum salt, which is applied in the field of extracting aluminum salt and recovering waste acid, can solve the problems of product quality deterioration, crystal acid water content, low use value, etc., and achieve low production cost and low process energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

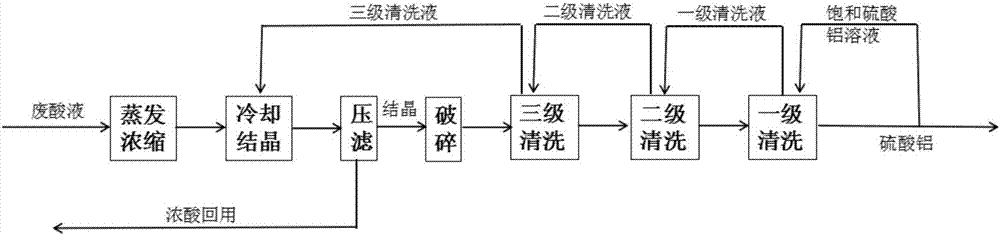

[0021] Such as figure 1 Shown, overall step of the present invention is:

[0022] a. Evaporation and concentration:

[0023] Evaporate and concentrate the acid solution containing aluminum salt by means of multi-effect evaporation or mechanical compression and re-evaporation, and increase the acid concentration in the acid solution to 35% to 70% by controlling the vacuum degree and temperature of the acid solution at the outlet; , the content of anions in the acid solution increases, and the solubility of aluminum salts in the acid solution decreases due to the same ion effect;

[0024] b. Cooling crystallization:

[0025] Pump the evaporated and concentrated acid solution into the crystallization tank, keep the temperature in the tank lower than 15°C, and keep the temperature above 3 hours, so that the aluminum salt in the acid so...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap