Low temperature closed-loop treatment process of waste glass fiber

A treatment process and closed-loop technology, applied in the field of waste glass fiber treatment process, can solve the problems of high energy consumption, waste gas harm, and the proportion cannot meet production requirements, and achieve the effect of considerable economic benefits and broad development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

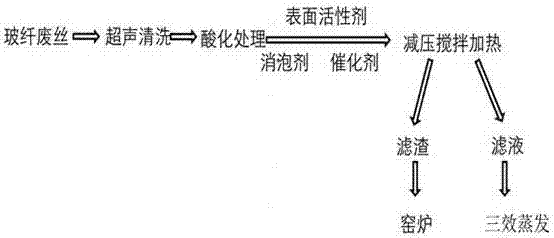

[0029] The low-temperature closed-loop treatment process of epoxy resin type glass fiber waste silk comprises the following steps:

[0030] (1) Ultrasonic cleaning of epoxy resin-type glass fiber waste silk, the ultrasonic frequency is 70KHz, the cleaning time is 15min, and dried at 80°C for 5h after cleaning;

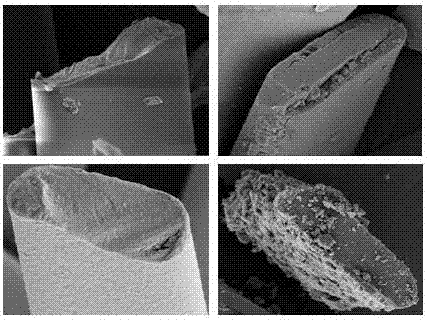

[0031] (2) After drying, the waste glass fiber is cut into short filaments with a length of about 1mm, and is sent to the airflow ultrafine pulverizer under the drive of the airflow. Pass through 200 mesh sieve;

[0032] (3) Place the sieved waste glass fiber powder in inorganic acid for about 8 hours to impregnate and activate. The inorganic acid accounts for about 5% of the total weight of the glass fiber powder. The selected inorganic acids are 1.5mol / L nitric acid and 0.8mol / L L dichromic acid mixed solution, the effect of soaking in inorganic acid is to make the wetting agent on the surface of glass fiber powder swell and destroy the cross-linked network structur...

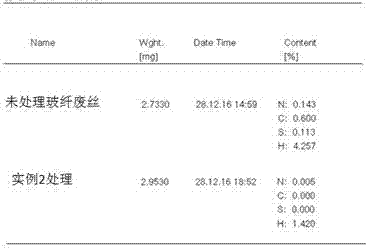

Embodiment 2

[0038] A low-temperature closed-loop treatment process for polyester fiberglass waste, comprising the following steps:

[0039] (1) Ultrasonic cleaning of waste polyester fiberglass, the ultrasonic frequency is 90KHz, the cleaning time is 10min, and dried at 90°C for 3h after cleaning;

[0040] (2) After drying, the waste glass fiber is cut into short filaments with a length less than 2mm, and is sent to the airflow ultrafine pulverizer driven by the airflow. The airflow speed is above 1.8MHz and the delivery pressure is 1MPa. 200 mesh sieve;

[0041] (3) Soak the sieved waste glass fiber powder in a mixed solution of 10 parts of 0.2-0.8mol / L perchloric acid and 20 parts of 2-3mol / L sulfuric acid accounting for 10% of the total weight of the glass fiber powder for 10 hours, so that The sizing agent on the surface of the glass fiber powder swells, destroying the cross-linked network structure between it and the glass fiber;

[0042] (4) Remove the acid solution by filtration ...

Embodiment 3

[0048] A low-temperature closed-loop treatment process for acrylate-type glass fiber waste, comprising the following steps:

[0049] (1) Ultrasonic cleaning of acrylate-type glass fiber waste, the ultrasonic frequency is 80KHz, the cleaning time is 12min, and dried at 90°C for 3h after cleaning;

[0050] (2) After drying, the waste glass fiber is cut into short filaments with a length less than 2mm, and is sent to the airflow ultrafine pulverizer under the drive of the airflow. Pass through a 200-mesh sieve;

[0051] (3) Soak the sieved waste glass fiber powder in 10 parts of 20% hydrochloric acid, 15% dichromic acid and 15% perchloric acid solution accounting for 3% of the total weight of glass fiber powder for 8 hours (dichromic acid solution and The volume ratio of perchloric acid solution is 1:1), so that the sizing agent on the surface of the glass fiber powder will swell and destroy the cross-linked network structure between it and the glass fiber;

[0052] (4) Remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com