Cellulosic ethanol distilling method

A technology of cellulosic ethanol and ethanol vapor, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of large differences in fermented mash components and inapplicability to cellulosic ethanol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

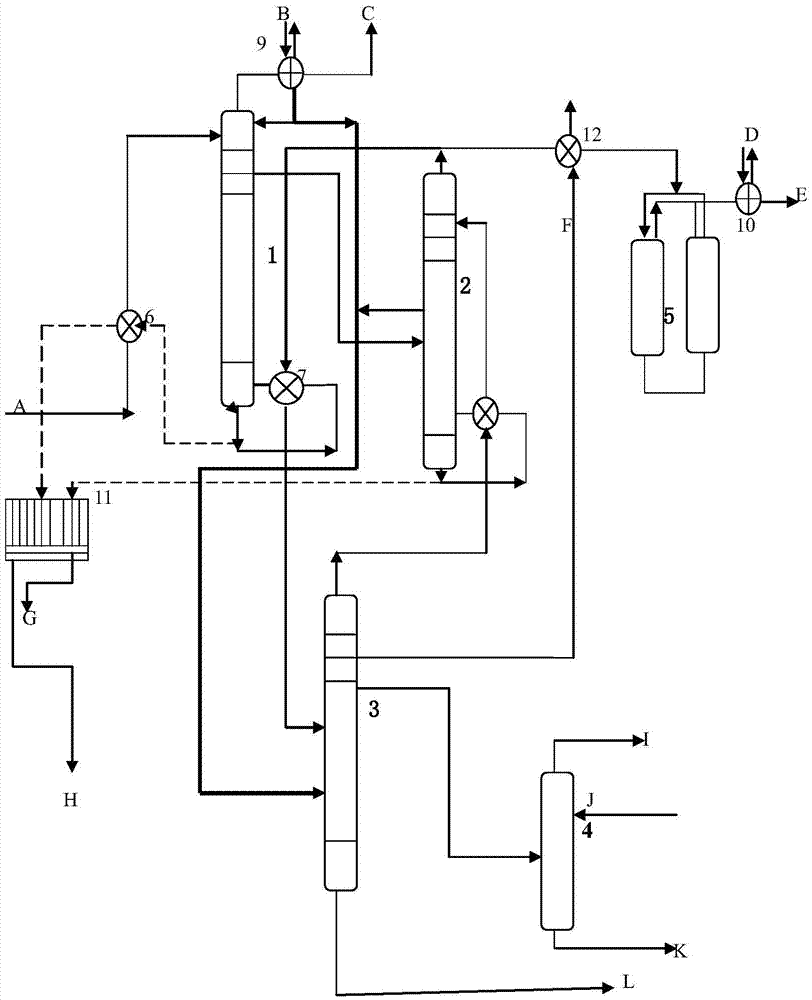

[0044] According to a preferred embodiment of the present invention, the distillation conditions of the first distillation tower 1 include: the number of trays is 16-18, the temperature at the top of the tower is 63-65°C, and the pressure at the top of the tower is -0.045 to -0.04 Mpa, the temperature of the tower kettle is 83-85°C, and the pressure of the tower kettle is -0.055 to -0.05Mpa.

[0045] More preferably, the distillation conditions of the first distillation tower 1 include: the number of trays is 16-18, the tray form is a floating valve, the tray efficiency is 45-55%, and the tray spacing is 0.5-0.6 meters, The reflux ratio is 1.8-2.

[0046] In the present invention, the content of ethanol in the first ethanol vapor may be 35-40% by weight.

[0047] In the present invention, the first ethanol vapor passes through the condenser 9 of the first distillation column to form ethanol condensate, and the condensation conditions can be selected conventionally in the field,...

Embodiment 1

[0068] This example is used to illustrate the method for distilling cellulose ethanol provided by the present invention.

[0069] In this example, the fermented mash is the fermented mash obtained by pretreatment, enzymolysis and fermentation of corn stalks. The content of each component in the fermented mash is: ethanol 5.4% by weight, water 76.6% by weight, acids 1.55% by weight, residual sugar 2.9% by weight, solid content 13% by weight, glycerin 0.75%. This example is in figure 1 in the device shown.

[0070] Such as figure 1 As shown, the fermented mash A exchanges heat with the material extracted from the bottom of the first distillation tower 1 in the feed heat exchanger 6 to obtain the heated fermented mash. The temperature of the fermented mash before the heat exchange is 30 ℃, the temperature of the fermented mash after heating is 63 ℃. The heated fermented mash enters the first distillation tower 1. The heated fermented mash is mass-transferred on the tray of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com