Method for recycling acetate fibers from cigarette butt filter tip

A technology of cellulose acetate and filter tips, which is applied in the direction of separation methods, chemical instruments and methods, and crystallization separation, can solve the problems of non-quantitative, restricted application range, and high cost of ionic liquids, and achieves mild and controllable operating conditions, low cost, and high technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

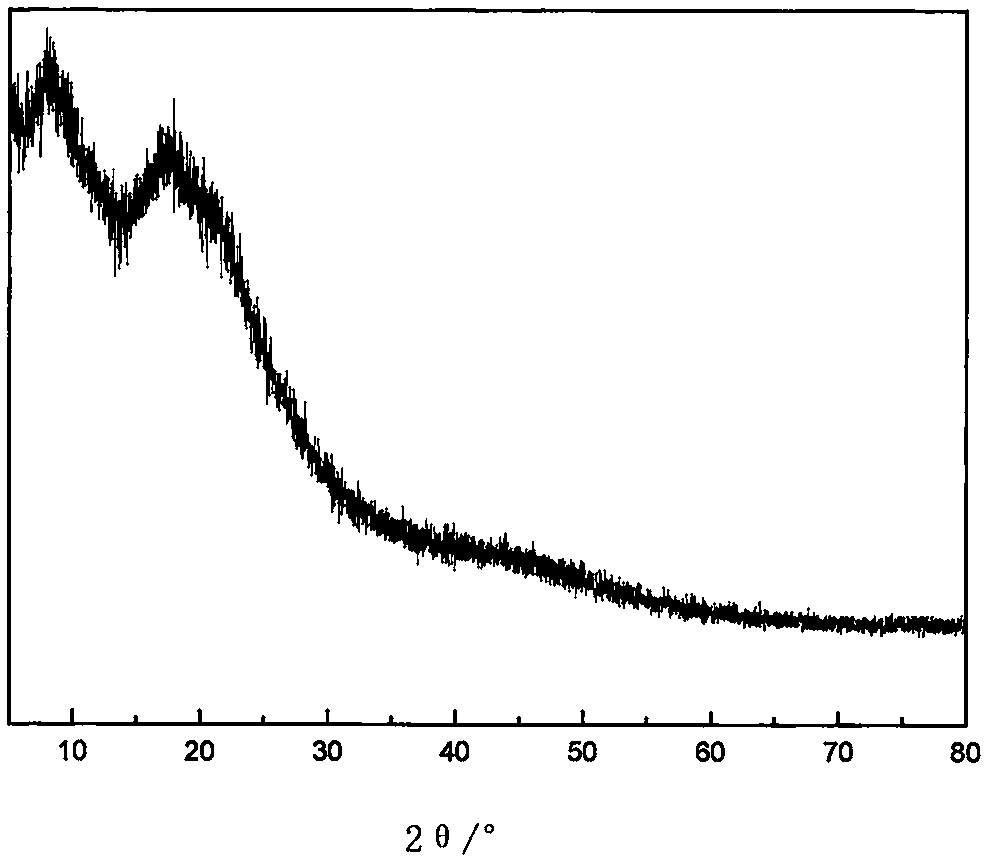

Embodiment 1

[0044] React the pretreated cigarette butt with 50mL of glacial acetic acid at 95°C for 4h, wash the product with deionized water, let the liquid stand at room temperature for 2h, the solid precipitates, and wash repeatedly until the conductivity of the washing liquid is equal to that of deionized water. Conductivity, the solid was dried at 80°C for 3 hours to obtain cellulose acetate.

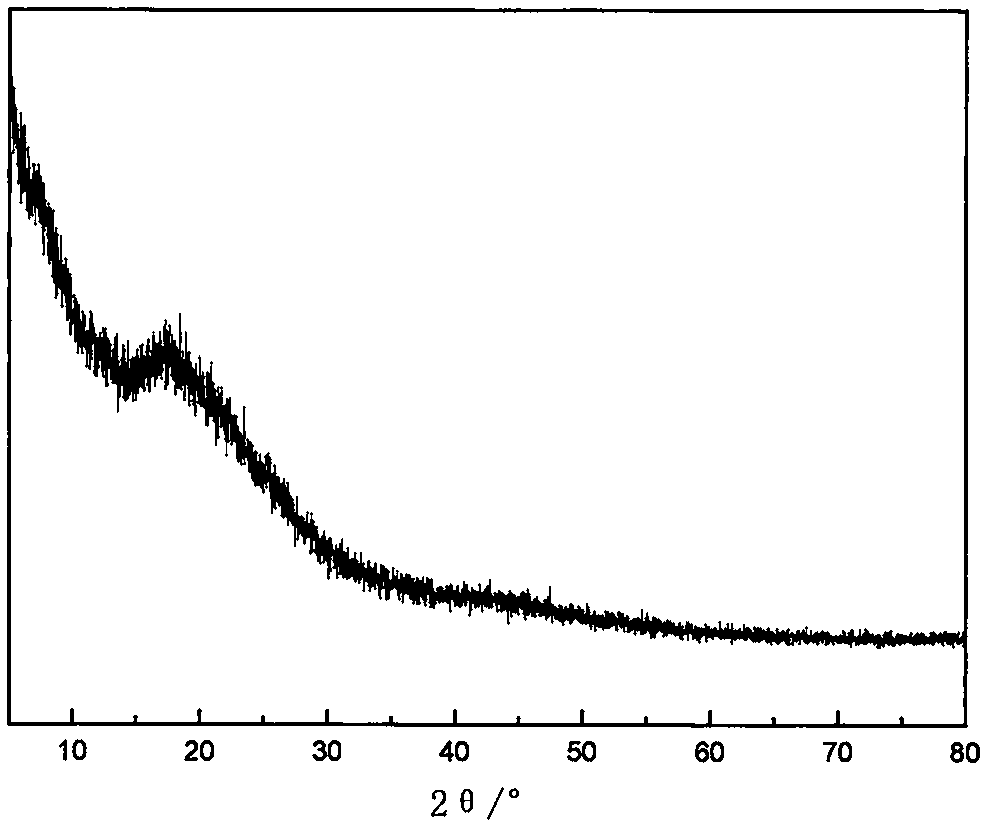

Embodiment 2

[0046] React the pretreated cigarette butt with 50mL glacial acetic acid at 95°C for 0.25h, wash the product with deionized water, let the liquid stand at room temperature for 2h, and the solid precipitates out, wash repeatedly until the conductivity of the washing liquid is deionized water Conductivity, the solid was dried at 80°C for 3 hours to obtain cellulose acetate.

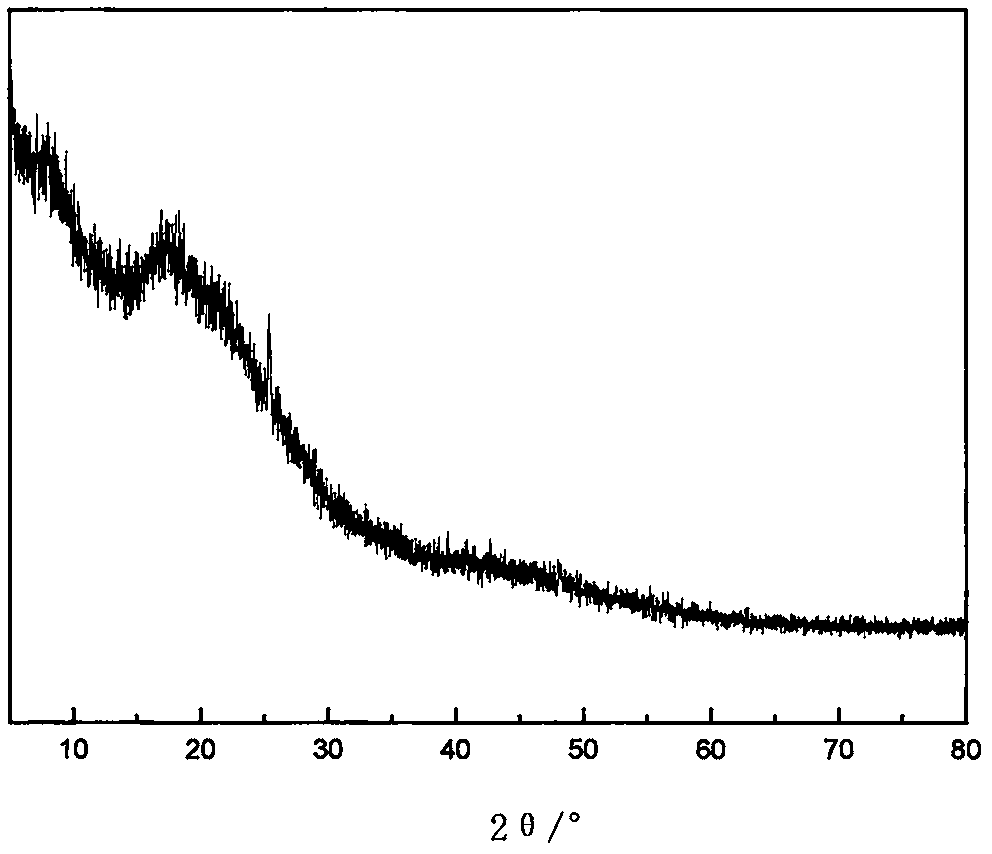

Embodiment 3

[0048] React the pretreated cigarette butt with 30mL of glacial acetic acid at 95°C for 4 hours, wash the product with deionized water, let the liquid stand at room temperature for 2 hours, the solid precipitates out, and wash repeatedly until the conductivity of the washing liquid is equal to that of deionized water. Conductivity, the solid was dried at 80°C for 3 hours to obtain cellulose acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com