Efficient antibacterial liquid laundry detergent and production method thereof

A laundry detergent, high-efficiency technology, applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of single antibacterial ingredients, skin irritation, skin corrosion, etc., and achieve good bactericidal and antibacterial effects, The effect of protecting clothing fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

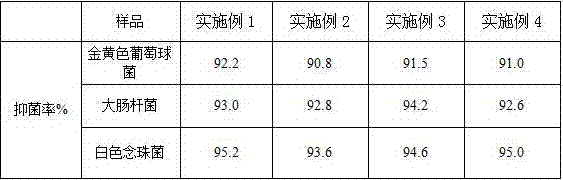

Examples

Embodiment 1

[0031] Raw materials (by mass percentage):

[0032] 1% olive oil, 1% coconut oil, 10% nonionic surfactant, 0.5% ginger extract, 0.5% passion fruit extract, 0.1% natural essence, 0.1% thickener, 0.05% plant antibacterial agent, deionized water balance.

[0033] production method:

[0034]Put the deionized water into the mixing mixer according to the formula amount, heat the deionized water to 50°C-60°C, add non-ionic surfactant, stir for 5-10 minutes, then add thickener and continue stirring for 5-10 minutes ;When the mixture is cooled below 35°C, add olive oil, coconut oil, ginger extract, passion fruit extract, natural essence and plant antibacterial agent, stir for 10-20 minutes, and finally filter and age the semi-finished product after sampling and testing , Finished product sampling inspection, filling, finished product packaging.

Embodiment 2

[0036] Raw materials (by mass percentage):

[0037] 3% olive oil, 2% coconut oil, 12% non-ionic surfactant, 1% ginger extract, 1% passion fruit extract, 0.5% natural essence, 1% thickener, 0.5% plant antibacterial agent, deionized water balance.

[0038] The production method of above efficient antibacterial laundry detergent is the same as embodiment 1.

Embodiment 3

[0040] Raw materials (by mass percentage):

[0041] 4% olive oil, 3% coconut oil, 14% non-ionic surfactant, 1.5% ginger extract, 1.5% passion fruit extract, 0.8% natural essence, 1.5% thickener, 0.8% plant antibacterial agent, deionized water balance.

[0042] The production method of above efficient antibacterial laundry detergent is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com