Zirconium-based alloy used in high-temperature environment of nuclear reactor

A high-temperature environment, zirconium-based alloy technology, applied in the field of zirconium alloy materials, can solve problems such as inability to meet performance requirements, and achieve excellent radiation creep resistance, improved mechanical properties, and radiation creep resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

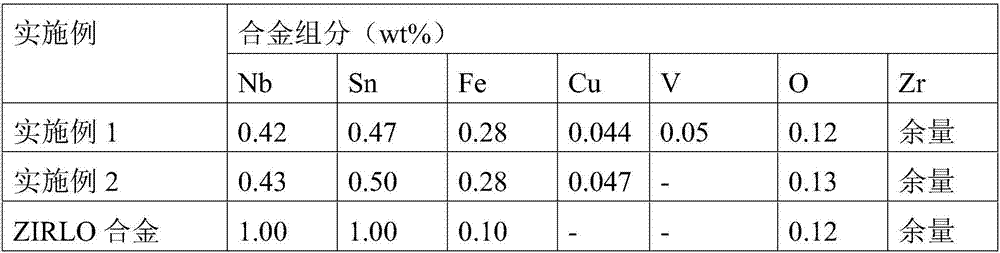

[0029] Zirconium-based alloys used in the high-temperature environment of nuclear reactors, calculated by weight percentage, include: Sn: 0.36-0.69%; Nb: 0.20-0.49%; Fe: 0.21-0.40%; O: 0.10-0.20%; 0.09% Cu or composite addition of 0.01-0.09% Cu and 0.01-0.20% V; the balance is at least 98% zirconium containing impurities.

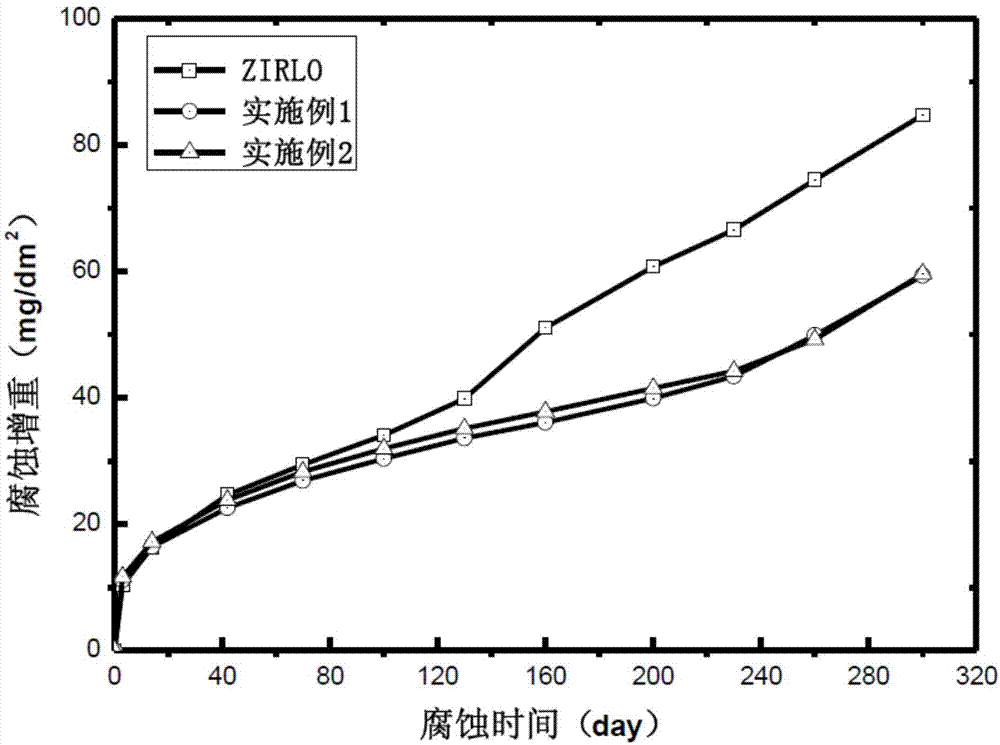

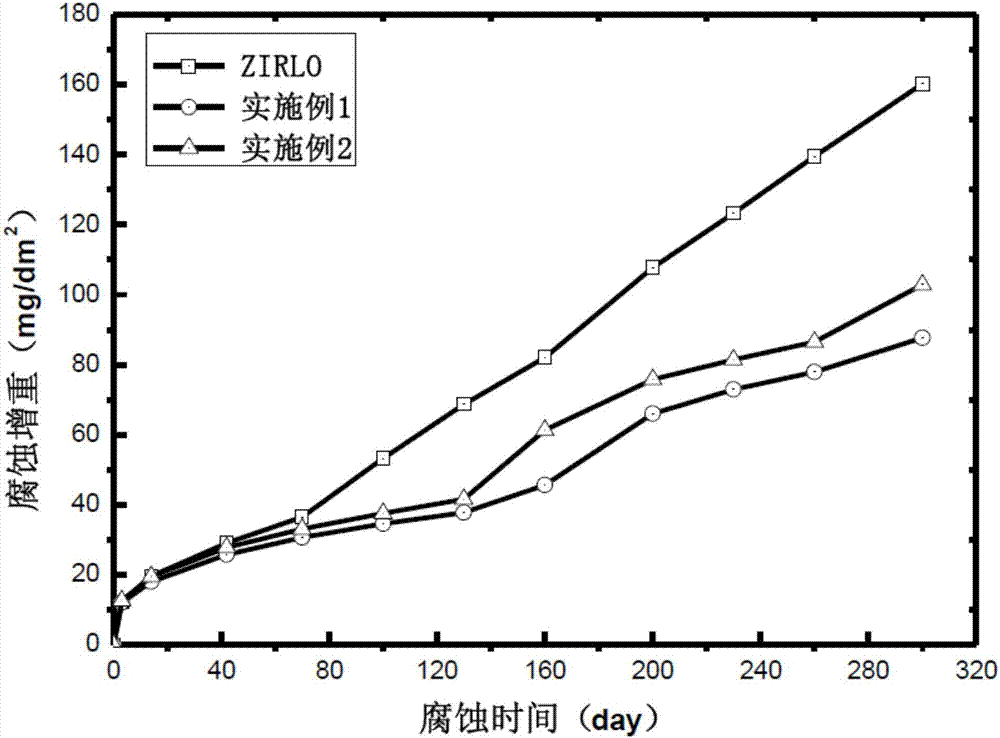

[0030] The compositions of the two examples and the comparative ZIRLO alloy are shown in Table 1.

[0031] Table 1

[0032]

[0033] The remaining impurity content is in line with the current standard of zirconium alloys for nuclear use, and the C and N impurity elements that are harmful to corrosion performance have been strictly controlled. The C content is less than 120μg / g, and the N content is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com