Method for refining trelagliptin

A refining method, the technology of ethyl acetate, applied in the direction of organic chemistry, can solve the problems of poor cleaning effect, low yield, waste of raw materials, etc., and achieve the effect of improving purity, high yield, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A refining method of Trexagliptin, comprising the steps of:

[0036] S1. Mix the crude product of trexagliptin, ethyl acetate and ethanol, reflux and stir for 2-4h, add molecular sieves, continue to reflux and stir for 1-2h, filter while hot to take the filtrate, cool down to 0-5°C, and stir for 2-3h , filter to get the filter cake, and dry to obtain the intermediate;

[0037] S2. Mix the intermediate obtained in S1 with ethyl acetate and isopropanol, reflux and stir for 3-5 hours, cool down to 0-5° C., stir for 3-4 hours, filter to take the filter cake, and dry to obtain Trexagliptin.

Embodiment 2

[0039] A refining method of Trexagliptin, comprising the steps of:

[0040] S1. Mix 1 kg of trexagliptin crude product, 5 L of ethyl acetate and 0.5 L of ethanol, stir at reflux for 3 h, add 0.03 kg of 4A molecular sieve with a particle size of 2 mm, continue stirring at reflux for 1.5 h, filter while hot to take the filtrate, and cool down to 2°C, stirred for 2.5h, filtered to take the filter cake, heated to 57°C, dried under reduced pressure for 10h to obtain 0.927kg of intermediate;

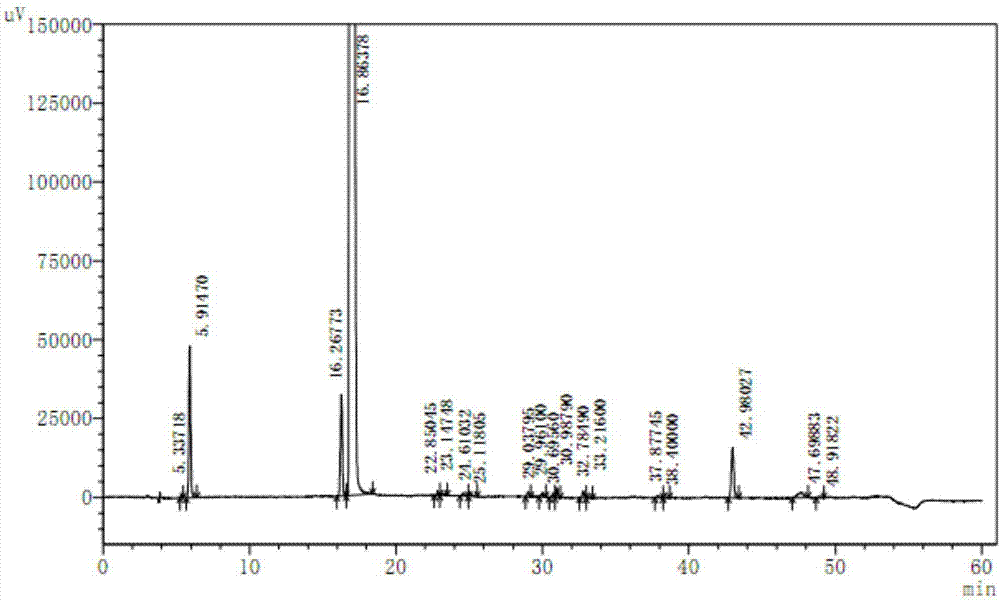

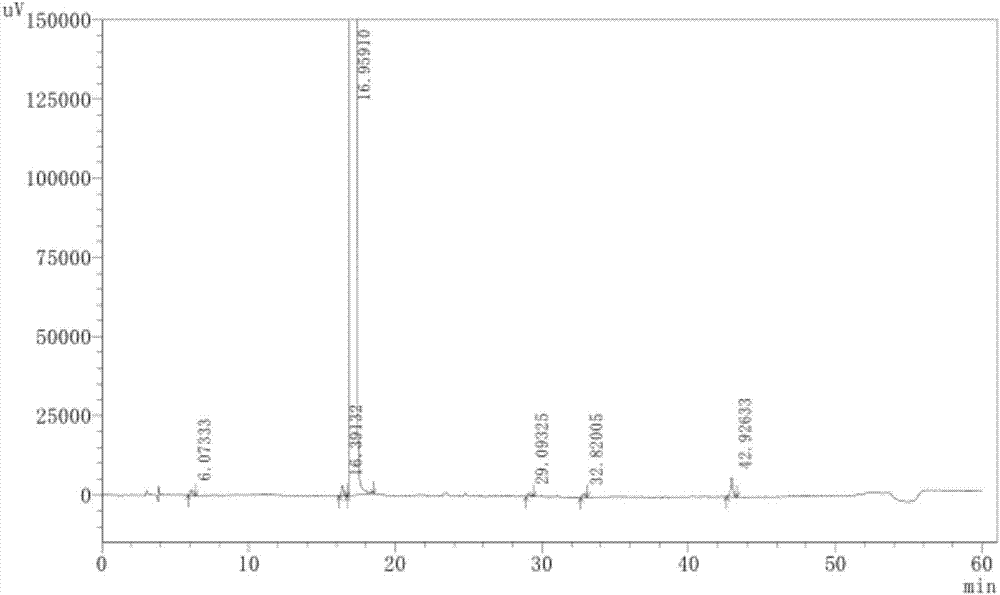

[0041] S2. Mix 0.927 kg of the intermediate obtained in S1 with 4.635 L of ethyl acetate and 1.391 L of isopropanol, stir at reflux for 4 hours, cool down to 3°C, stir for 3.5 hours, filter to take the filter cake, heat up to 57°C, and depressurize After drying for 10 hours, 0.828kg trexagliptin was obtained. The crude product of Trexagliptin and Trexagliptin were detected by high performance liquid chromatography, the results are shown in figure 1 and figure 2 , figure 1 It is the HPLC c...

Embodiment 3

[0043] A refining method of Trexagliptin, comprising the steps of:

[0044] S1. Mix 1 kg of troxagliptin crude product, 9 L of ethyl acetate and 1 L of ethanol, stir at reflux for 2 h, add 0.01 kg of 4A molecular sieves with a particle size of 2.5 mm, continue stirring at reflux for 1 h, filter while hot to take the filtrate, and cool to Stir at 5°C for 2h, filter to take the filter cake, heat up to 60°C, dry under reduced pressure for 8h to obtain 0.905kg of intermediate;

[0045] S2. Mix 0.905 kg of the intermediate obtained in S1 with 5.43 L of ethyl acetate and 1.086 L of isopropanol, stir at reflux for 5 hours, cool down to 0°C, stir for 4 hours, filter to take the filter cake, heat up to 55°C, and dry under reduced pressure 12h obtained 0.802kg trexagliptin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com