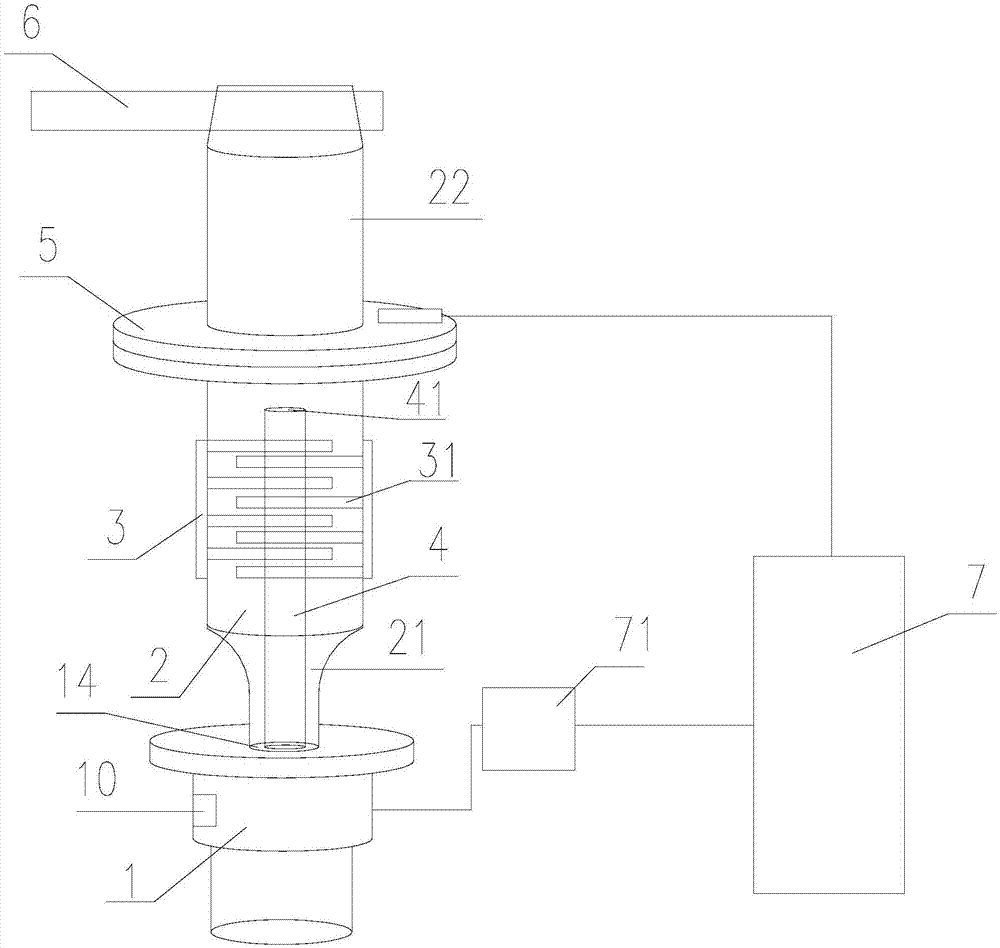

Special food packaging and fresh-keeping film for high speed machine, and making method thereof

A food preservation, high-speed machine technology, applied in the field of packaging materials, can solve the problems of difficult self-adhesion and tensile properties, film breaking and shutdown, etc., and achieve the effects of high stretchability, good self-adhesion and high tensile properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

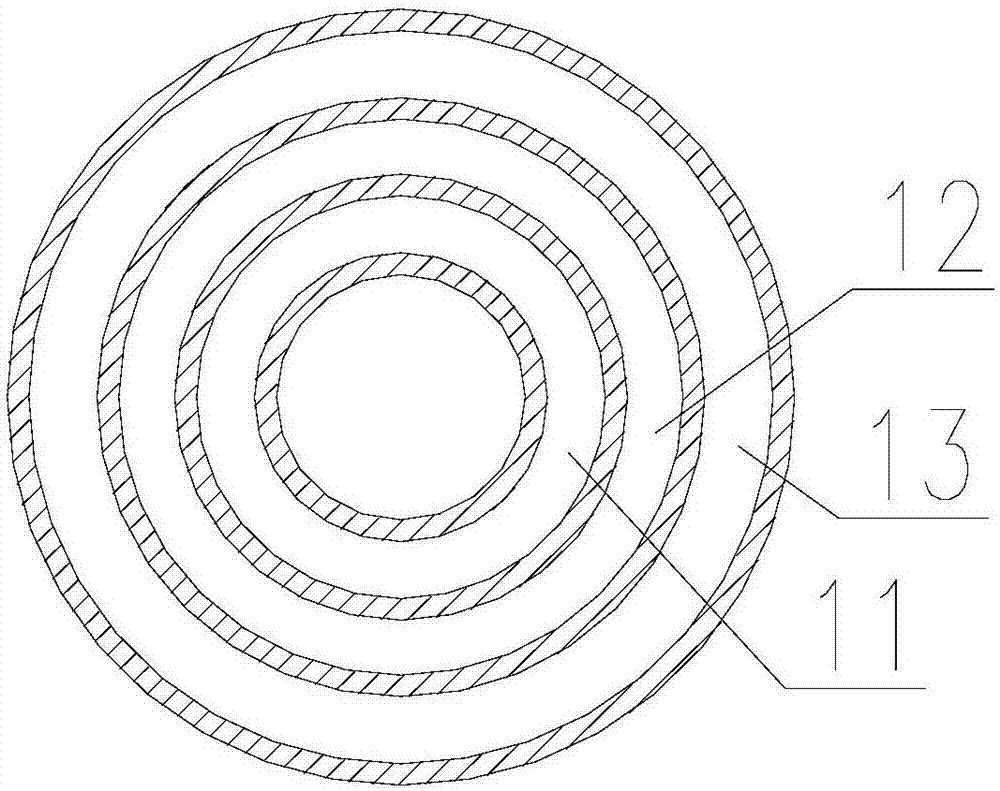

[0035] In terms of mass fraction, the inner layer material includes:

[0036] Ethylene vinyl acetate polymer 15%

[0037] Linear Low Density Polyethylene Polymer 75%

[0038] Functional masterbatch 10%;

[0039] In terms of mass fraction, the middle layer material contains:

[0040] Metallocene Linear Low Density Polyethylene 25%

[0041] Polypropylene polymer 45%;

[0042] In terms of mass fraction, the outer layer material includes:

[0043] Ethylene vinyl acetate polymer 15%

[0044] Linear Low Density Polyethylene Polymer 80%

[0045] Functional masterbatch 10%

[0046] The functional masterbatch in the inner material and the outer material is a mixture of glycerol monooleate and long-chain fatty acid ester.

[0047] In the middle layer material, the molecular weight of the polypropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com