Preparation method and application of oxygen sustained release and phosphorus absorption material

A mixture and calcium peroxide technology, applied in the field of materials, can solve the problems of fast oxygen release, poor durability, secondary pollution, etc., and achieve the effects of long oxygen release duration, simple and easy method, and good phosphorus absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of an oxygen slow-release, phosphorus-absorbing material, the specific steps are as follows:

[0025] (1) After uniformly mixing iron-carrying granular biochar, calcium peroxide particles, Portland cement, and quartz sand, it is standby to obtain the mixture;

[0026] Preferably, the iron-loaded granular biochar is prepared from walnut shell particles, and the specific preparation method is as follows: the walnut shell particles are placed in Fe 3+ Immerse in the impregnation solution with a concentration of 0.5-1.0mol / L for more than 12 hours, and then carbonize the impregnated walnut shell particles at 480-520°C for 80-100min under anaerobic conditions, and the obtained iron-carrying granular biochar particles diameter is 1-2mm; the particle diameter of the calcium peroxide particles is 90-110 mesh, and the purity is 70-80%; the Portland cement is 425 Portland cement; the particle size of the quartz sand is The diameter is 1-2mm.

[0027] Prefer...

Embodiment 2

[0033] The test of material phosphorus removal effect of the present invention is as follows:

[0034] Through the static adsorption test, when the initial phosphorus concentration is 5mg / L, 50mg / L, the solution volume is 100mL, and the weight of oxygen slow-release and phosphorus-absorbing materials are 0.81g, 0.85g, 1.55g, 1.62g respectively, after 4 hours The equilibrium adsorption capacity is shown in Tables 1 and 2 below.

[0035] Phosphorus removal effect under each example operating condition of table 1

[0036]

[0037] Phosphorus removal effect under each example operating condition of table 2

[0038]

[0039] It can be seen from Tables 1 and 2 that this material has a good adsorption effect on both low and high concentrations of phosphorus in the solution.

Embodiment 3

[0041] Material of the present invention is as follows to the test of simulated river dephosphorization, oxygen release effect:

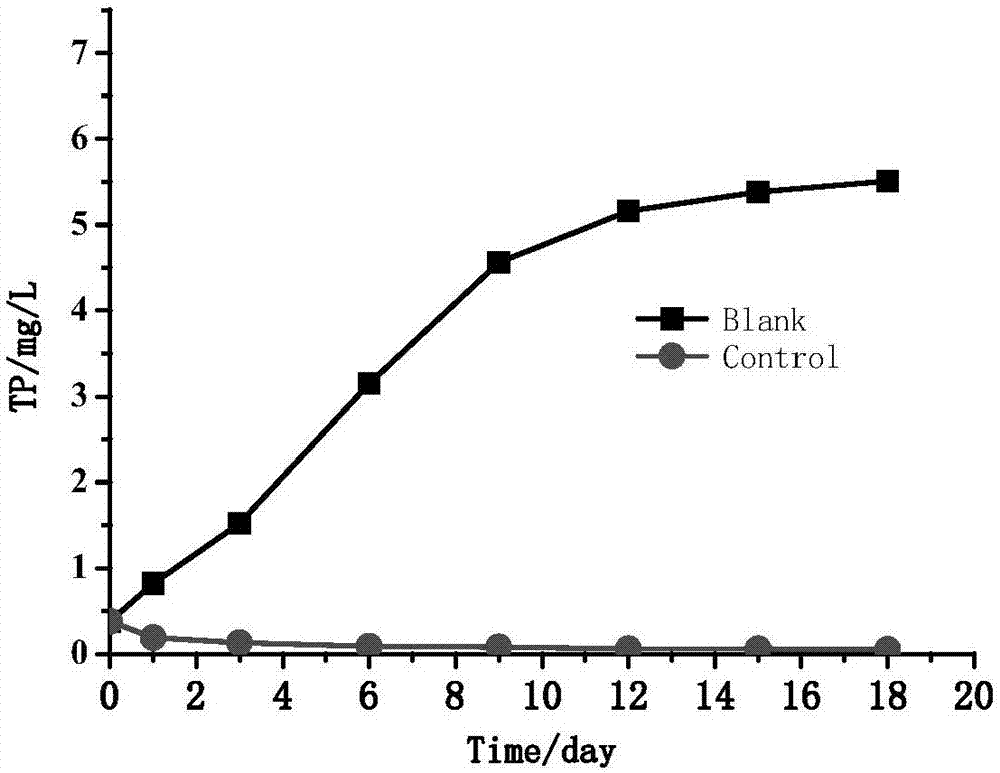

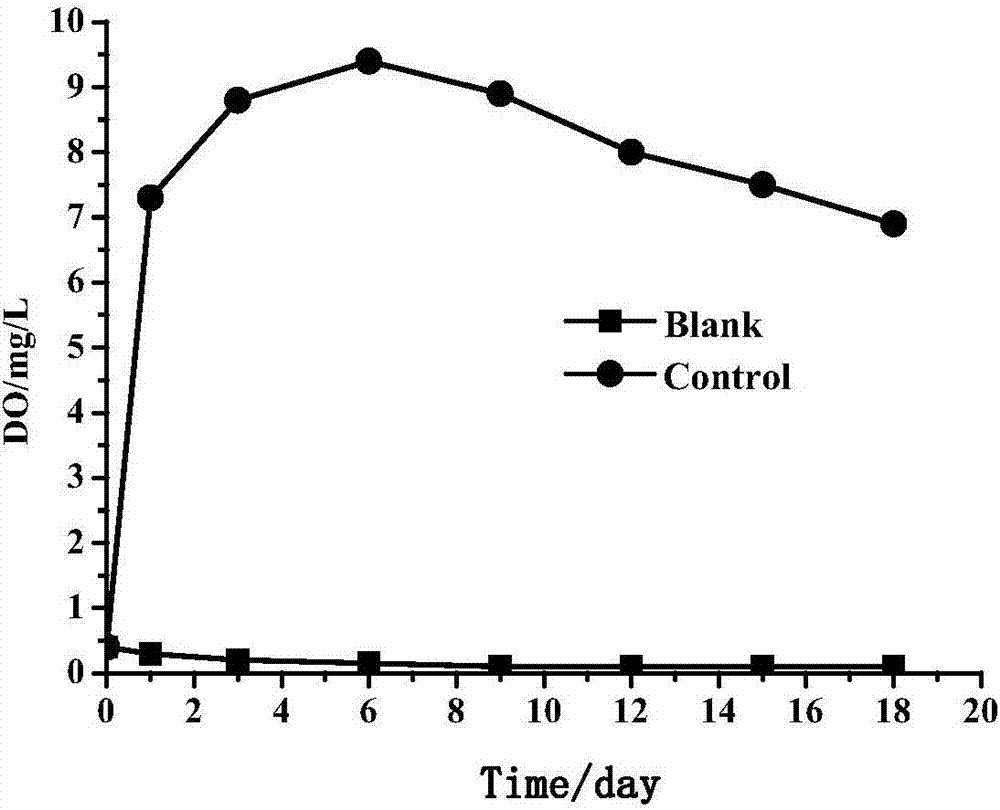

[0042] 10cm of river sediment was filled in two groups of simulated reactors respectively, and the depth of water covered by the sediment was 40cm. In group 1 (blank group), the upper port of the reactor was immediately closed after nitrogen deoxygenation for 10 minutes to reduce the influence of atmospheric oxygen coverage. Group 2 (experimental group), after 10 minutes of deoxygenation with nitrogen, add 400g, cover 2cm thick oxygen slow-release phosphorus absorbing material, close the upper opening of the reactor to reduce the influence of atmospheric oxygen covering, at 0, 3, 6, 9, On the 12th, 15th, 18th, 21st, 24th, and 27th days, samples were taken to measure the total phosphorus in the overlying water and the dissolved oxygen concentration in the overlying water in the simulated reactor. The result is as follows figure 1 , figure 2 shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com