Anhydrous stemming

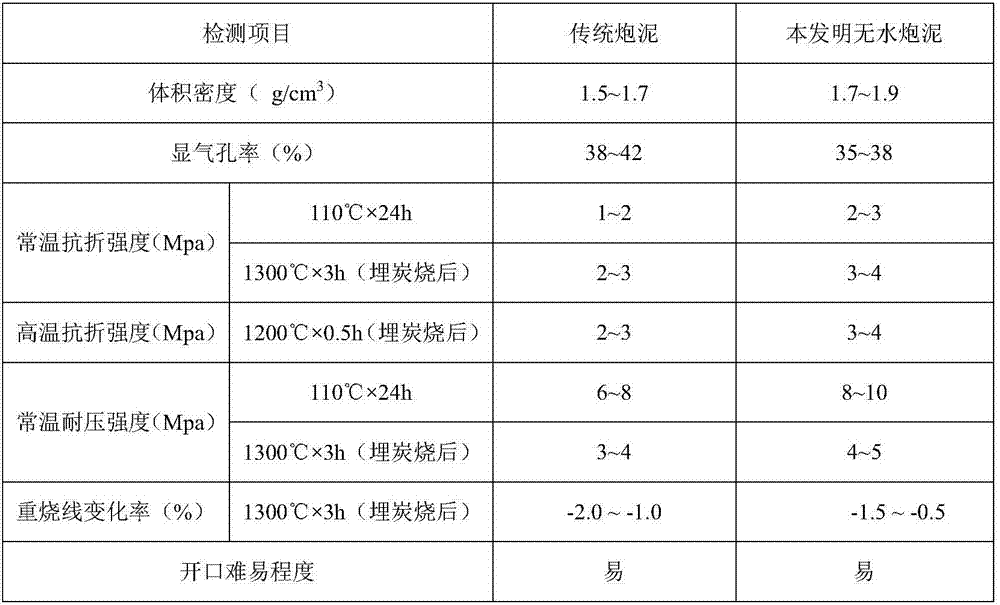

An anhydrous taphole clay and particle size technology, applied in the field of refractory materials, can solve the problems of poor slag resistance, high temperature resistance and erosion resistance, burnt out equipment in front of the furnace, wet iron mouth and other problems, and achieve excellent erosion resistance, The effect of prolonging the tapping time and fast coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

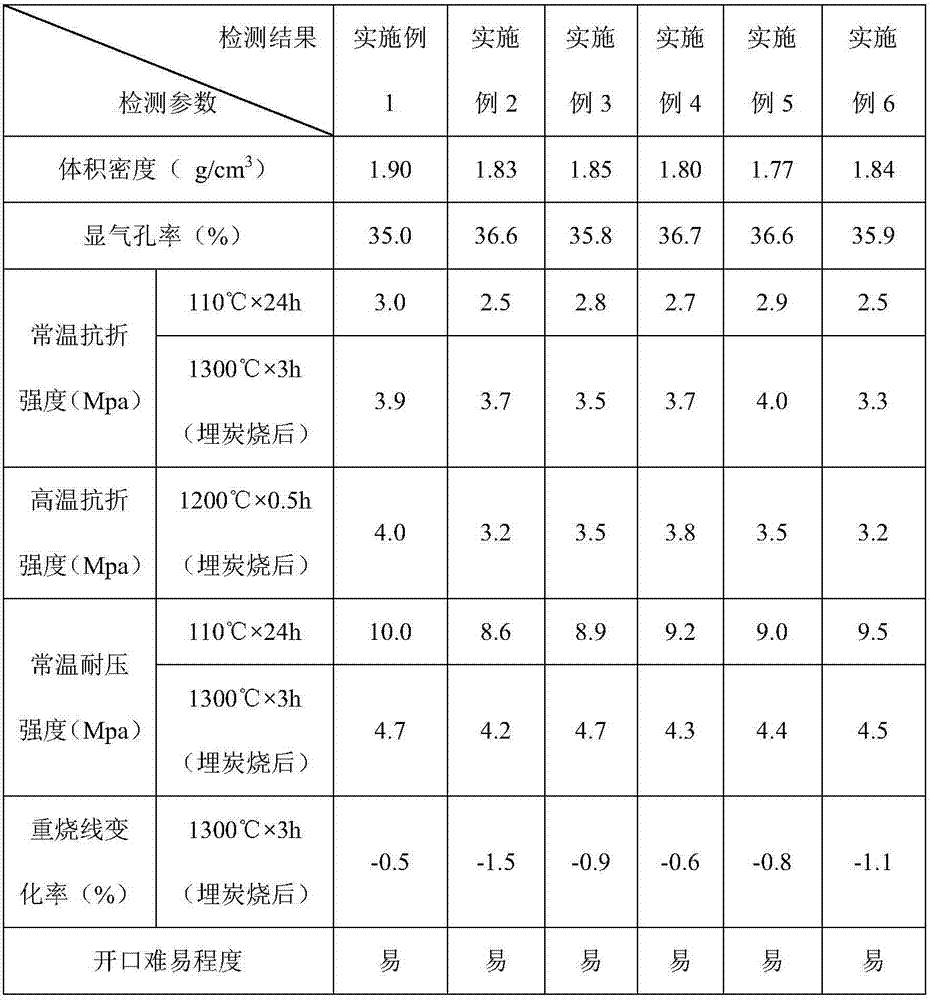

Embodiment 1

[0018] A kind of waterless taphole clay, represented by weight percentage, the raw material of described waterless taphole clay is composed of: 7% of coke foam with a particle size of 2-0mm, 8% of sericite with a particle size of 200 mesh, and 3% of aluminum oxide powder , 5% silicon carbide with a particle size of 200 mesh, 10% high-bauxite with a particle size of 3-1mm, 15% high-bauxite with a particle size of 1-0mm, 8% high-bauxite with a particle size of 200, and a particle size of 200 8% brown corundum, 2% metal silicon powder with a particle size of 200 mesh, 4% asphalt powder, 2% kyanite with a particle size of 40-70 mesh, 2% earthy graphite, 8% clay, 8% bentonite and silicon nitride 10% iron, plus a binding agent accounting for 10% of the total weight of the above-mentioned raw materials, and the binding agent is tar.

Embodiment 2

[0020] A kind of waterless taphole clay, represented by weight percentage, the raw material of described waterless taphole clay is composed of: 10% of coke foam with a particle size of 2-0mm, 5% of sericite with a particle size of 200 mesh, and 4% of aluminum oxide powder , 8% of silicon carbide with a particle size of 200 mesh, 12% of high-bauxite with a particle size of 3-1mm, 12% of high-bauxite with a particle size of 1-0mm, 5% of high-bauxite with a particle size of 200, and a particle size of 200 10% brown corundum, 3% metal silicon powder with a particle size of 200 mesh, 5% asphalt powder, 3% kyanite with a particle size of 40-70 mesh, 2% earthy graphite, 5% clay, 10% bentonite and silicon nitride 6% iron, plus a binding agent accounting for 12% of the total weight of the above-mentioned raw materials, and the binding agent is tar.

Embodiment 3

[0022] A kind of waterless taphole clay, represented by weight percentage, the raw material of described waterless taphole clay is composed of: 8% of coke foam with a particle size of 2-0mm, 10% of sericite with a particle size of 200 mesh, and 5% of aluminum oxide powder , 5% of silicon carbide with a particle size of 200 mesh, 15% of high-bauxite with a particle size of 3-1mm, 10% of high-bauxite with a particle size of 1-0mm, 10% of high-bauxite with a particle size of 200 mesh, and a particle size of 200 5% brown corundum, 4% metal silicon powder with a particle size of 200 mesh, 4% asphalt powder, 3% kyanite with a particle size of 40-70 mesh, 3% earthy graphite, 5% clay, 5% bentonite and silicon nitride 8% iron, plus a binding agent accounting for 15% of the total weight of the above raw materials, the binding agent is tar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com