Modified hemicellulose-based paper strengthening agent and preparation method therefor

A hemicellulose-based paper technology, applied in the direction of reinforcing agent addition, can solve the problems of difficult use of paper-making reinforcing agents, difficulty in grafting modification of hemicellulose, and low performance of hemicellulose-based reinforcing agents, and achieve good practical results. Application value, good application value, good performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Hemicellulose, polyethylene glycol (molecular weight: 2000) and isocyanate were weighed in an amount (molar ratio) of 0.29:0.1:1.

[0024] (2) N,N-dimethylformamide and tetrahydrofuran mixed liquid that configuration volume ratio is 1:9 are used as the reaction solvent of modified hemicellulose;

[0025] (3) Transfer the reactant of step (1) and the solvent of step (2) to a round-bottomed flask, place it on a heating stirrer, and stir for 10 min under a nitrogen atmosphere to make the reactant mix uniformly;

[0026] (4) The reaction temperature was set to 90° C., the reaction time was 8 h, and nitrogen was used for protection during the reaction.

[0027] (5) The product was washed three times with ether, and dried at room temperature to obtain a modified hemicellulose-based paper strengthening agent of this embodiment.

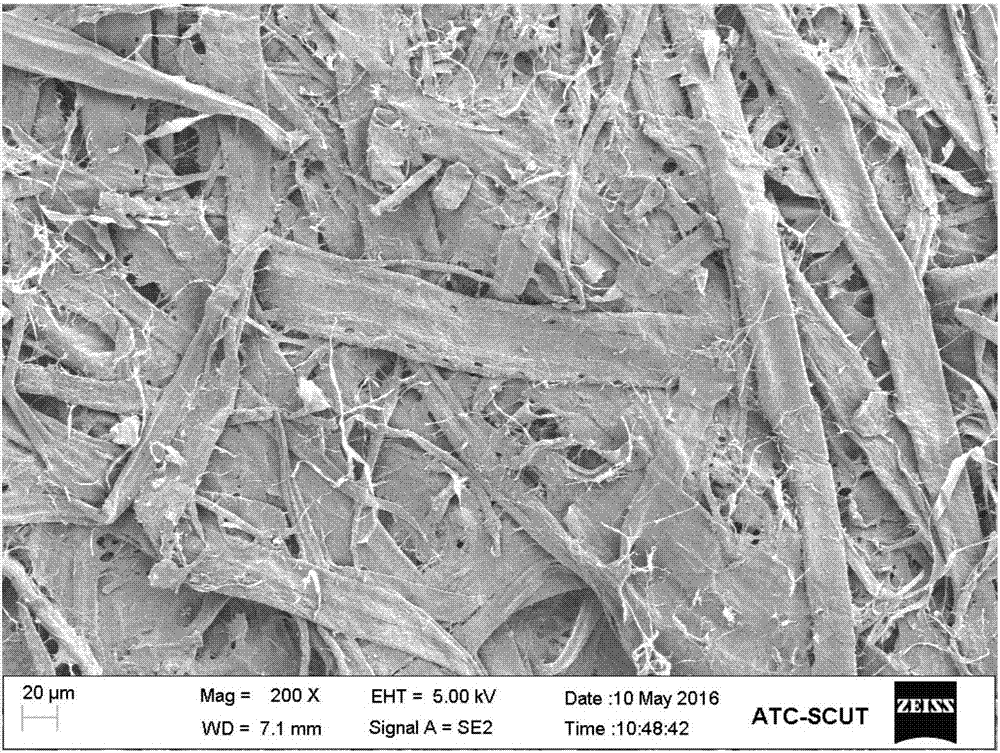

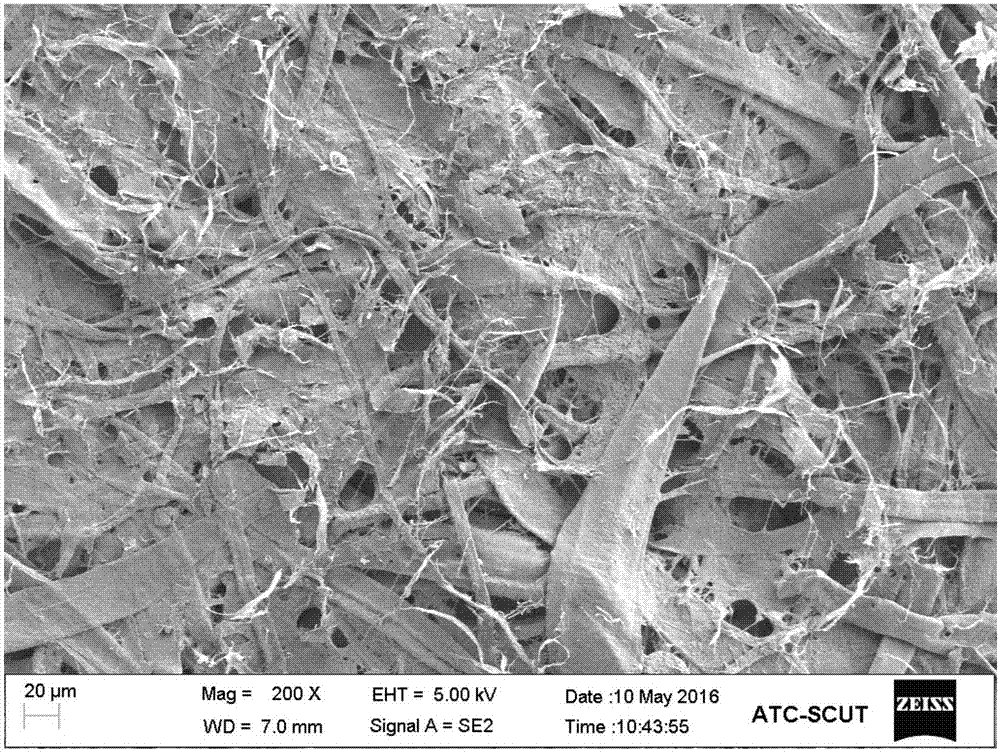

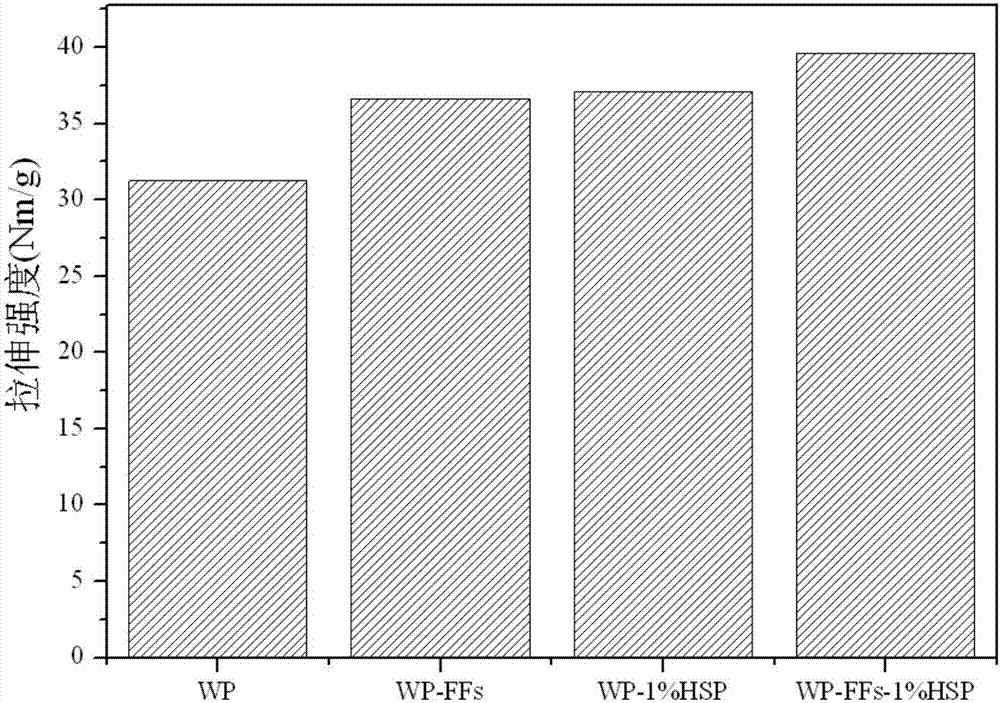

[0028] The application performance test of the modified hemicellulose-based paper strengthening agent obtained in the present embodiment:

[00...

Embodiment 2

[0037] (1) Weigh hemicellulose, polyethylene glycol (molecular weight: 2000) and isocyanate with a molar ratio of 0.29:0.1:1.

[0038] (2) N,N-dimethylformamide and tetrahydrofuran mixed liquid that configuration volume ratio is 1:5 are used as the reaction solvent of modified hemicellulose;

[0039] (3) The reactant of step (1) and the solvent of step (2) are transferred in a round bottom flask, placed on a heating stirrer, and stirred for 15min under a nitrogen atmosphere, so that the reactant is evenly mixed;

[0040] (4) The reaction temperature was set to 100° C., the reaction time was 10 h, and nitrogen was used for protection during the reaction.

[0041] (5) The product was washed three times with ether, and dried at room temperature to obtain a modified hemicellulose-based paper strengthening agent of this embodiment.

Embodiment 3

[0043] (1) Weigh hemicellulose, polyethylene glycol (molecular weight: 2000) and isocyanate with a molar ratio of 0.29:0.1:1.

[0044] (2) N,N-dimethylformamide and tetrahydrofuran mixed liquid that configuration volume ratio is 5:5 are used as the reaction solvent of modified hemicellulose;

[0045] (3) The reactant of step (1) and the solvent of step (2) are transferred to a round-bottomed flask, placed on a heating stirrer, and stirred for 20 min under a nitrogen atmosphere, so that the reactant is evenly mixed;

[0046] (4) The reaction temperature was set to 110° C., the reaction time was 8 h, and nitrogen was used for protection during the reaction.

[0047] (5) The product was washed three times with ether, and dried at room temperature to obtain a modified hemicellulose-based paper strengthening agent of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com