A kind of preparation method of sericin/glycerin blend film and its product and application

A technology of blending film and glycerin, which is applied in the field of biomaterials, can solve the problems of low toxicity and biocompatibility, and achieve the effects of promoting healing, strong antibacterial and growth inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of sericin / glycerin blend film, comprising the steps of:

[0030] (1) Preparation of sericin solution: cut silkworm cocoons into about 1cm 2 Put the fragments in a beaker, add deionized water according to 1g silkworm cocoons / 20ml water, filter and remove insoluble silk fibroin at 121°C, 0.1Mpa high temperature and high pressure for 30min, collect the filtrate, freeze-dry to obtain sericin powder; according to a certain proportion Take sericin powder and add deionized water to boil and dissolve to obtain a sericin solution with a mass concentration of 5%;

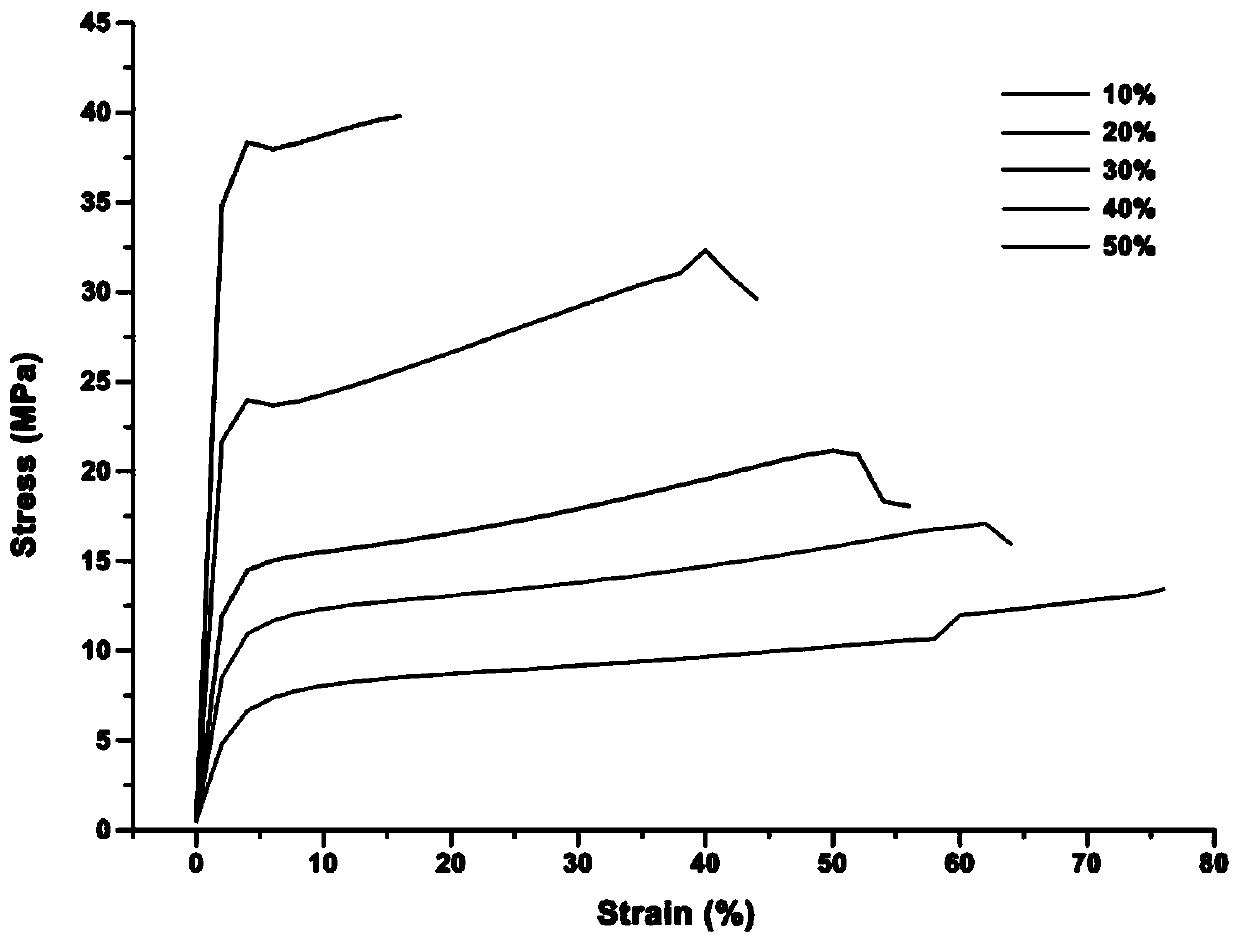

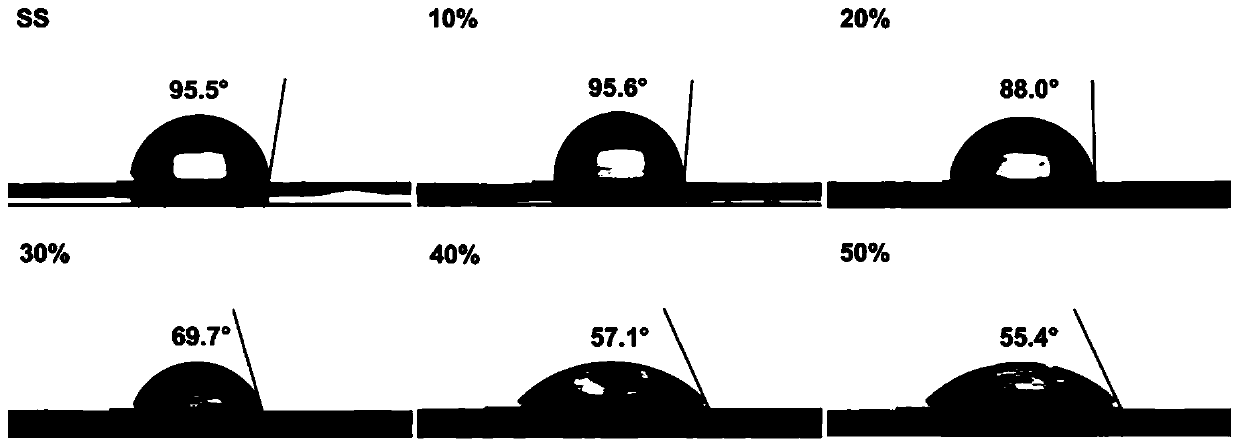

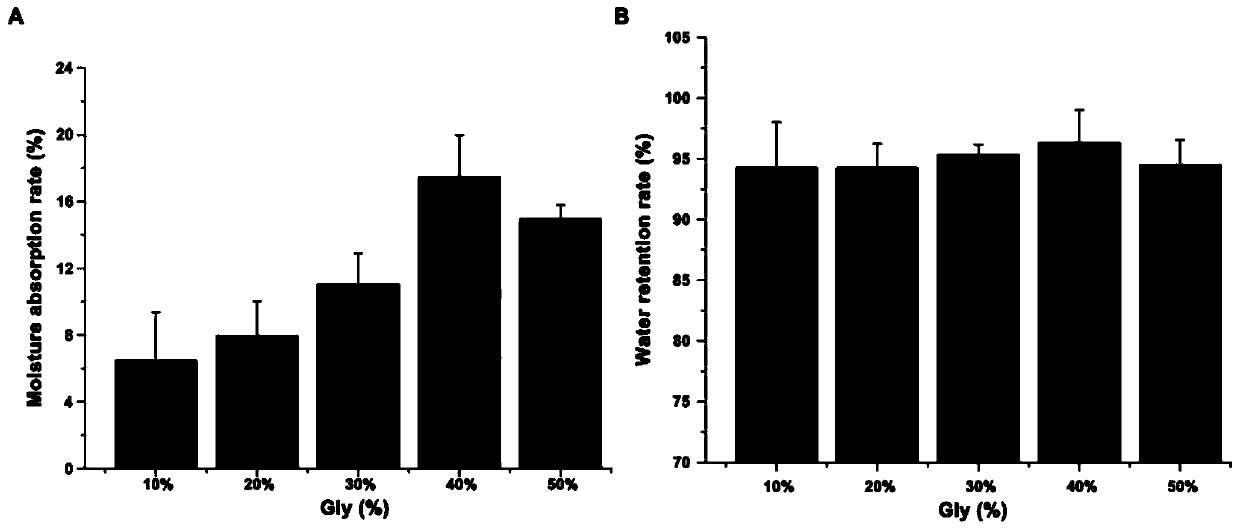

[0031](2) Preparation of sericin / glycerol blend membrane: add 20 μl, 40 μl, 60 μl, 80 μl, 100 μl of glycerin (density 1.25 g / ml) to the tanks containing 4.98ml, 4.96ml, 4.94ml, 4.92ml and 4.90 ml of a centrifuge tube with a mass concentration of 5% sericin solution, mix evenly, pour it into a mold, and dry it in a 65°C oven to form a film. The mass ratios of glycerol to sericin are 10%, 20%, 30%,...

Embodiment 2

[0037] The preparation method of nano silver / sericin / glycerol blend film comprises the steps:

[0038] Prepare a silver nitrate solution with a concentration of 50mM, cut the mixed film with a mass ratio of glycerol to sericin of 40% into small pieces, immerse it in the silver nitrate solution prepared now, and irradiate it with 365nm ultraviolet light for 20min, 40min, and 60min respectively. After drying at room temperature, nano-silver / sericin / glycerin blend films with different radiation reduction times were obtained.

[0039] In this embodiment, the purpose of the invention can be achieved when the concentration of the silver nitrate solution is 20-50 mM.

[0040] Scanning electron microscopy (SEM) (JCM-5000, JEOL, Tokyo, Japan) was used to observe the surface morphology of sericin / glycerin blend film and nano-silver / sericin / glycerol blend film to confirm the presence of nano-silver in sericin. Surface in situ synthesis of / glycerol blend membranes. The surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com