GPG-V gasification and pyrolysis integrated top-spray reactor and production equipment and technology

A technology for pyrolysis reaction and gasification reaction chamber, which is applied in the gasification process, the manufacture of combustible gas, and the gasification of granular/powdered fuel, etc. It can solve the problems of low utilization rate of raw materials, insignificant economic benefits, and immature technology. , to achieve the effect of wide adaptability of coal types, improved pyrolysis capacity, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

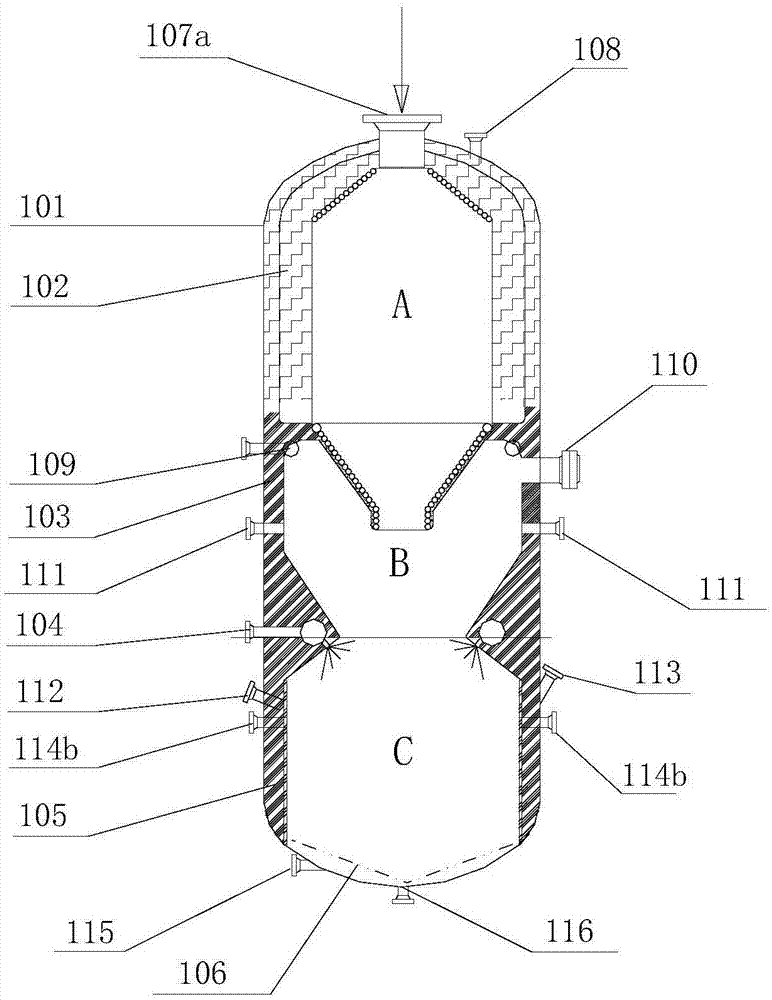

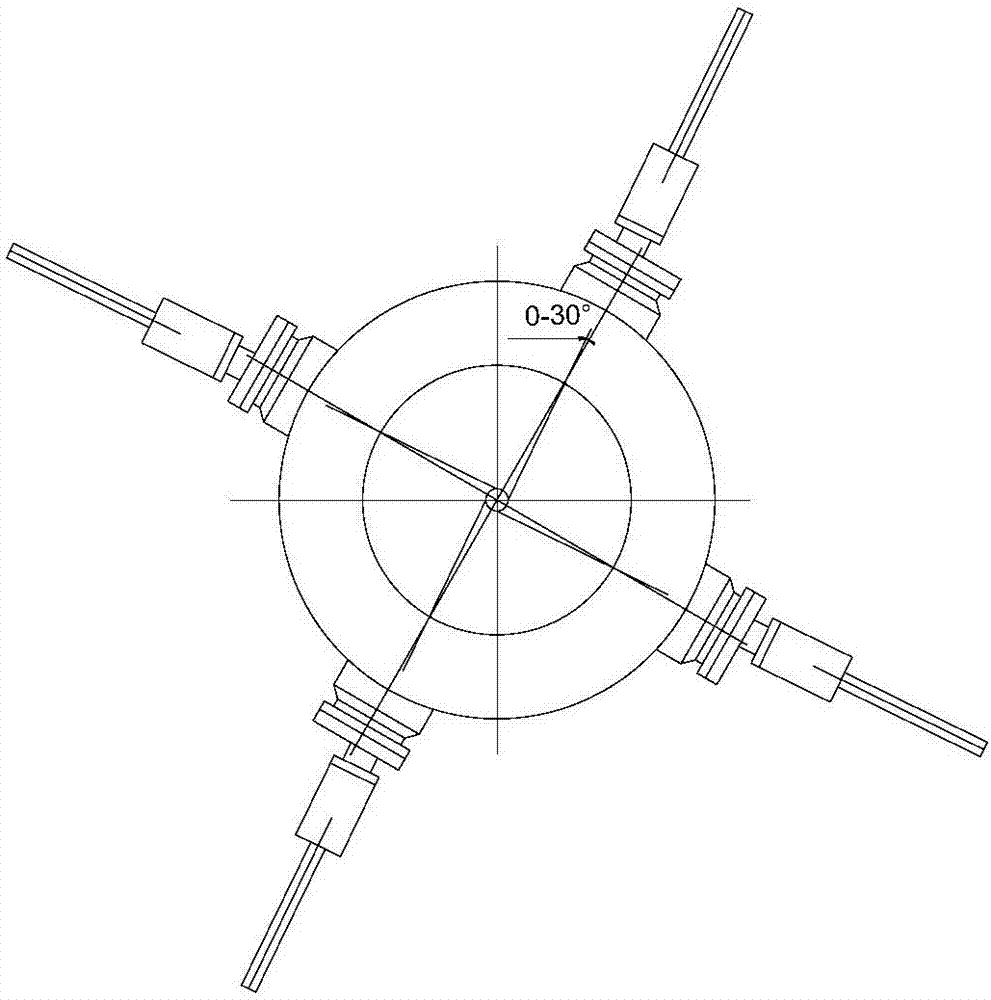

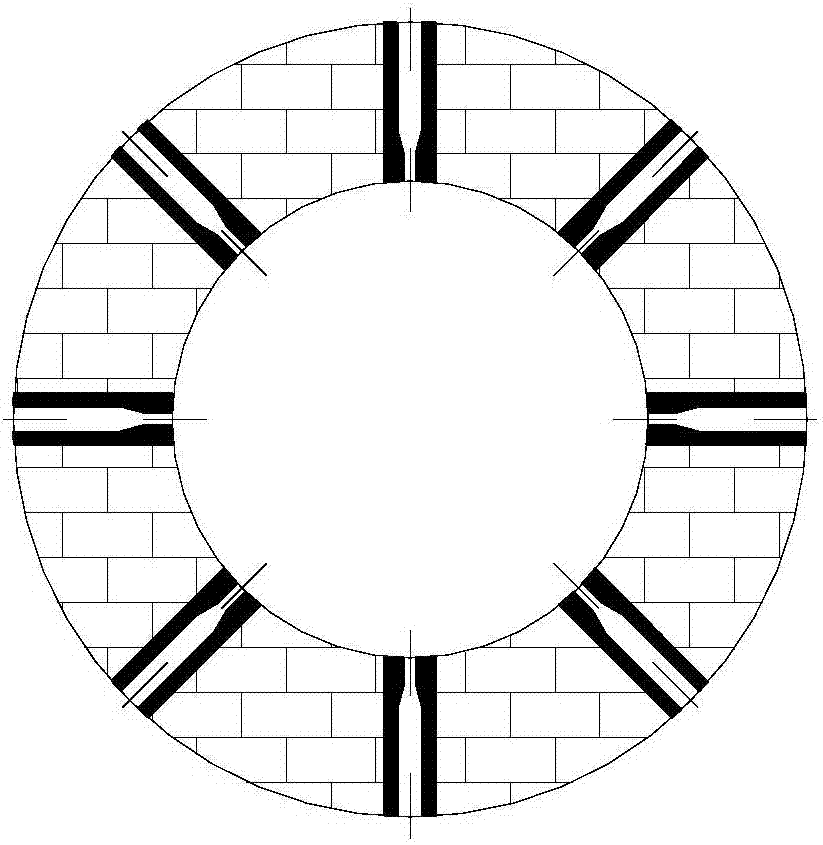

[0021] Such as figure 1 As shown, a GPG-V gasification and pyrolysis integrated top injection reactor includes a shell 101, an upper refractory and heat-insulating lining 102, a middle refractory and heat-insulating lining 103, a chilling device 104, a lower refractory and heat-insulating lining 105 and The fluidized plate 106, the upper refractory and heat-insulating lining 102 is arranged on the upper part of the inner side wall of the shell 101 to form a pulverized coal / coal slurry gasification reaction chamber A, and the top of the shell 101 is provided with a pulverized coal / coal slurry oxygen integrated The chemical nozzle a107 and the fire viewing hole 108, the middle refractory and heat-insulating lining 103 are arranged on the middle part of the inner side wall of the shell 101 to form a pyrolysis reaction chamber B, and the upper part of the pyrolysis reaction chamber B is provided with a hydrogen nozzle 109 and an ash tar gas outlet 110, a pulverized coal / coal slurr...

Embodiment 2

[0031] The GPG-V gasification and pyrolysis integrated top injection reactor and gasification and pyrolysis production device in this example are the same as those in Example 1.

[0032] A gasification pyrolysis production process, comprising the following steps:

[0033] The material is sprayed into the pulverized coal / coal slurry gasification reaction chamber A through the pulverized coal / coal slurry oxygen integrated nozzle a107 to react, and the generated high-temperature liquid slag and synthesis gas enter the pyrolysis reaction chamber B to be combined with the pulverized coal / coal slurry nozzle 111 mixes the materials injected with the hydrogen gas fed into the hydrogen nozzle 109 to undergo a pyrolysis reaction, and most of the coke ash in the materials generated by the reaction falls into the quenching device 104 due to gravity and the swirl flow in the pyrolysis reaction chamber, and the remaining part of the coke ash oil gas Through the ash tar gas outlet 110, the c...

Embodiment 3

[0037] The GPG-V gasification and pyrolysis integrated top injection reactor and gasification and pyrolysis production device in this example are the same as those in Example 1.

[0038] A gasification pyrolysis production process, comprising the following steps:

[0039] The material is sprayed into the pulverized coal / coal slurry gasification reaction chamber A through the pulverized coal / coal slurry oxygen integrated nozzle a107 to react, and the generated high-temperature liquid slag and synthesis gas enter the pyrolysis reaction chamber B to be combined with the pulverized coal / coal slurry nozzle 111 mixes the materials injected with the hydrogen gas fed into the hydrogen nozzle 109 to undergo a pyrolysis reaction, and most of the coke ash in the materials generated by the reaction falls into the quenching device 104 due to gravity and the swirl flow in the pyrolysis reaction chamber, and the remaining part of the coke ash oil gas Through the ash tar gas outlet 110, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com