Corrosion resistant spring steel for high-speed railway spring rods and production method thereof

A technology of high-speed railway and production method, applied in the field of metallurgy, can solve problems such as failure during overhaul, erosion, surface pitting of spring strips, etc., and achieve the effects of improved corrosion resistance, broad application prospects, and improved pitting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

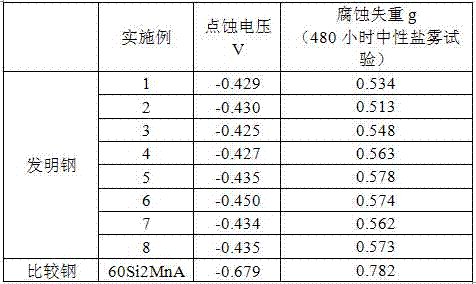

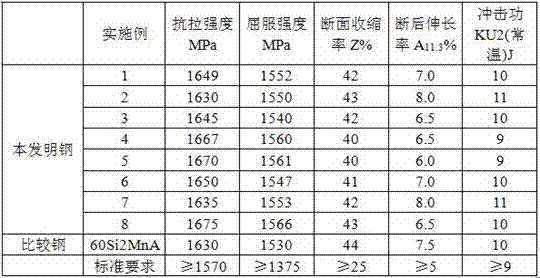

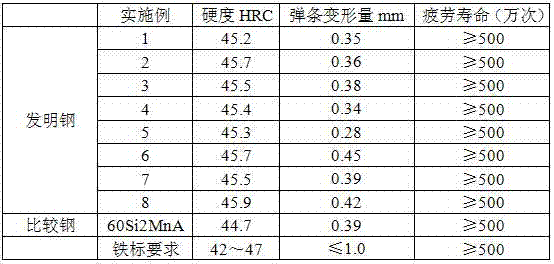

[0039] Corrosion-resistant spring steel for high-speed railway clips, see Table 1 for chemical composition and mass percentage.

[0040] The steel is rolled into Ф14mm spring steel, the hardness and mechanical properties are shown in Table 2.

[0041] The production method of corrosion-resistant spring steel for high-speed railway clips is as follows:

[0042] Converter smelting→LF refining→VD vacuum degassing→continuous casting→continuous casting slab heating→rolling;

[0043] Converter smelting: Converter smelting controls the C content at the end point of 0.09%, and the tapping temperature is controlled at 1640°C; during the tapping process, carburizers and alloy materials are added to make the chemical composition reach the lower limit of the target range; during the tapping process, pre-deoxidation is added and steel core is added Aluminum 1.0kg / ton of steel; slagging during tapping, adding lime 5.0kg / ton of steel and refining slag 4.0kg / ton of steel.

[0044] LF refini...

Embodiment 2

[0050] Corrosion-resistant spring steel for high-speed railway clips, see Table 1 for chemical composition and mass percentage.

[0051] The steel is rolled into Ф14mm spring steel, the hardness and mechanical properties are shown in Table 2.

[0052] The production method of corrosion-resistant spring steel for high-speed railway clips is as follows:

[0053] Converter smelting→LF refining→VD vacuum degassing→continuous casting→continuous casting slab heating→rolling;

[0054] Converter smelting: Converter smelting controls the C content at the end point of 0.11%, and the tapping temperature is controlled at 1650°C; during the tapping process, carburizers and alloy materials are added to make the chemical composition reach the lower limit of the target range; pre-deoxidation during tapping, adding steel core 1.5kg / ton of aluminum for steel; 5.5kg / ton of lime and 4.5kg / ton of refining slag for slagging during tapping.

Embodiment 3

[0061] Corrosion-resistant spring steel for high-speed railway clips, see Table 1 for chemical composition and mass percentage.

[0062] The steel is rolled into Ф14mm spring steel, the hardness and mechanical properties are shown in Table 2.

[0063] The production method of corrosion-resistant spring steel for high-speed railway clips is as follows:

[0064] Converter smelting→LF refining→VD vacuum degassing→continuous casting→continuous casting slab heating→rolling;

[0065] Converter smelting: Converter smelting controls the C content at the end point of 0.10%, and the tapping temperature is controlled at 1650°C; during the tapping process, carburizers and alloy materials are added to make the chemical composition reach the lower limit of the target range; during the tapping process, pre-deoxidation is added and steel core is added Aluminum 0.5kg / ton of steel; slagging during tapping, adding lime 3.5kg / ton of steel and refining slag 3.0kg / ton of steel.

[0066] LF refini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com