Method for preparing super-hydrophobic film on ultra-low carbon steel surface

An ultra-low carbon steel, super-hydrophobic technology, applied in the direction of metal material coating process, etc., can solve the problems of difficult modification of the production line, low production cost, large pollution, etc., achieve uniform and irregular morphology, improve corrosion resistance time and effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The ultra-low carbon steel substrate is an ultra-low carbon steel plate,

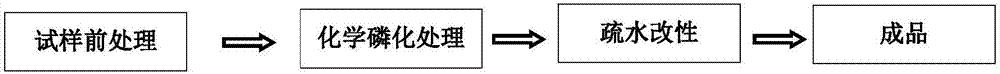

[0067] Step 1: Surface pretreatment of ultra-low carbon steel substrate

[0068] The ultra-low carbon steel substrate is pretreated. The pretreatment steps are: soak the ultra-low carbon steel substrate in alkali solution at 60°C for 5 minutes, take it out and rinse it with deionized water; then place the substrate at a concentration of 0.4mol / Dilute H of L 2 SO 4 Soak in the solution for 40s, after taking it out, rinse it with deionized water;

[0069] Wherein, the lye is composed of the following components Na 2 CO 3 : 20g / L, NaOH: 40g / L, NaOH 4 P 2 o 7 10H 2 O: 100g / L, emulsifier OP-10: 3g / L.

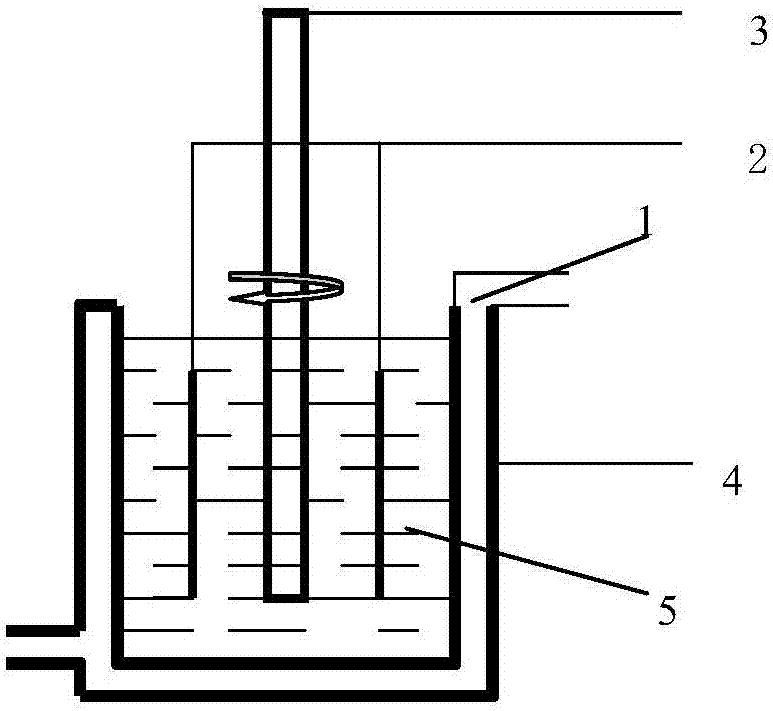

[0070] Step 2: Phosphating treatment

[0071] Immerse the ultra-low carbon steel substrate obtained in step 1 into the composite solution for phosphating treatment, and soak for 5 minutes at a temperature of 55°C; after phosphating, rinse the surface of the ultra-low carbon steel with deioniz...

Embodiment 2

[0077] The ultra-low carbon steel substrate is an ultra-low carbon steel plate.

[0078] Step 1: Same as Example 1.

[0079] Step 2: Phosphating treatment

[0080] Immerse the ultra-low carbon steel matrix obtained in step 1 into the composite solution for phosphating treatment, and soak for 10 minutes at a temperature of 60°C; after phosphating, rinse the surface of the ultra-low carbon steel with deionized water and dry to obtain phosphorus The material matrix after melting,

[0081] Wherein, the composite solution is composed of the following components: zinc dihydrogen phosphate 35g / L, nickel nitrate 9g / L, tartaric acid 1g / L.

[0082] Step three, surface hydrophobic treatment

[0083] The super-hydrophobic film on the surface of the ultra-low carbon steel was obtained by immersing the phosphating ultra-low carbon steel substrate in an ethanol solution of lauric acid with a concentration of 0.02 mol / L for 2 minutes for modification and drying.

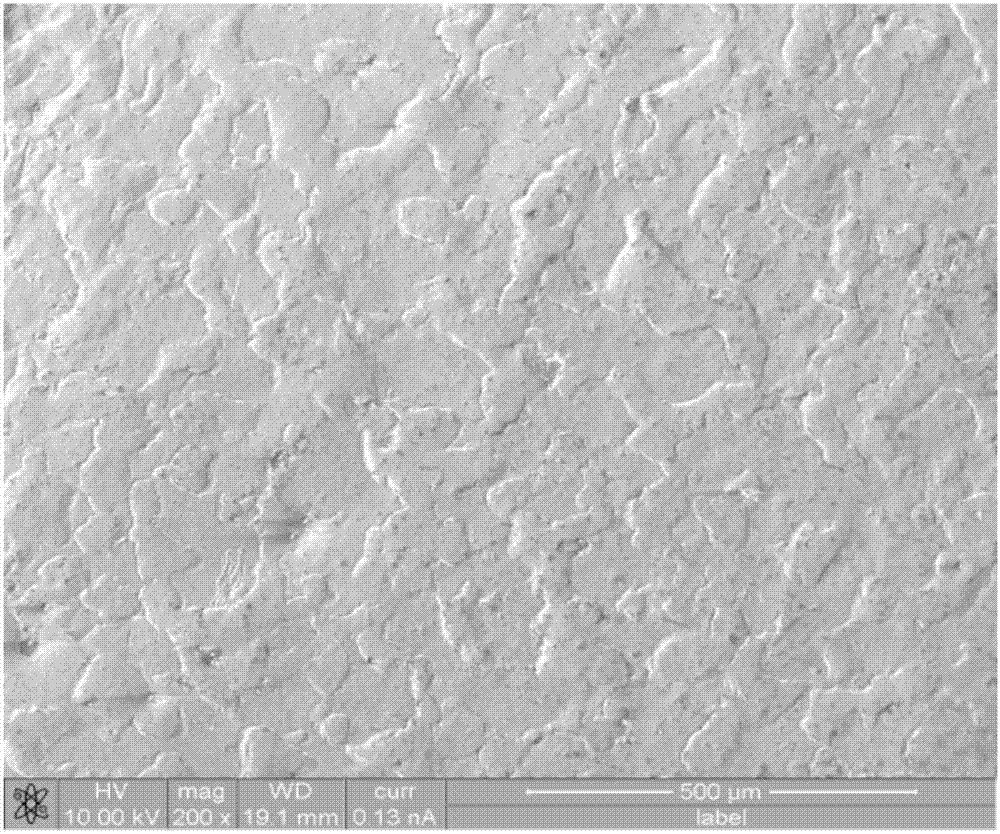

[0084] The characteristi...

Embodiment 3

[0086] The ultra-low carbon steel substrate is an ultra-low carbon steel plate.

[0087] Step 1: Same as Example 1.

[0088] Step 2: Phosphating treatment

[0089]Immerse the ultra-low carbon steel matrix obtained in step 1 into the composite solution for phosphating treatment, and soak for 15 minutes at a temperature of 65°C; after phosphating, rinse the surface of the ultra-low carbon steel with deionized water and dry to obtain phosphorus The material matrix after melting,

[0090] Wherein, the composite solution is composed of the following components: zinc dihydrogen phosphate 45g / L, nickel nitrate 10g / L, tartaric acid 2g / L.

[0091] Step three, surface hydrophobic treatment

[0092] The super-hydrophobic film on the surface of ultra-low carbon steel was obtained by immersing the phosphating ultra-low carbon steel substrate in the ethanol solution of myristic acid with a concentration of 0.03mol / L for 2 minutes for modification and drying.

[0093] The characteristics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Roughness value | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com