Cellulose-based carbon fibers, preparation method thereof and method for preparing electrode material

A technology for preparing electrodes and fiber electrodes, which is applied in battery electrodes, fiber chemical characteristics, circuits, etc., can solve the problems of restricting large-scale industrial application, high requirements for instruments and equipment, and increasing production costs, achieving abundant reserves, low prices, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiments of the present invention provide a method for preparing cellulose-based carbon fibers on the one hand, comprising the following steps:

[0037] S100. Preparation of cellulose raw materials: directly take cellulose-rich materials from plants as raw materials, wash the raw materials, boil them with alkali, beat them into fibers, wash them until they are neutral, and dry them to obtain cellulose raw materials;

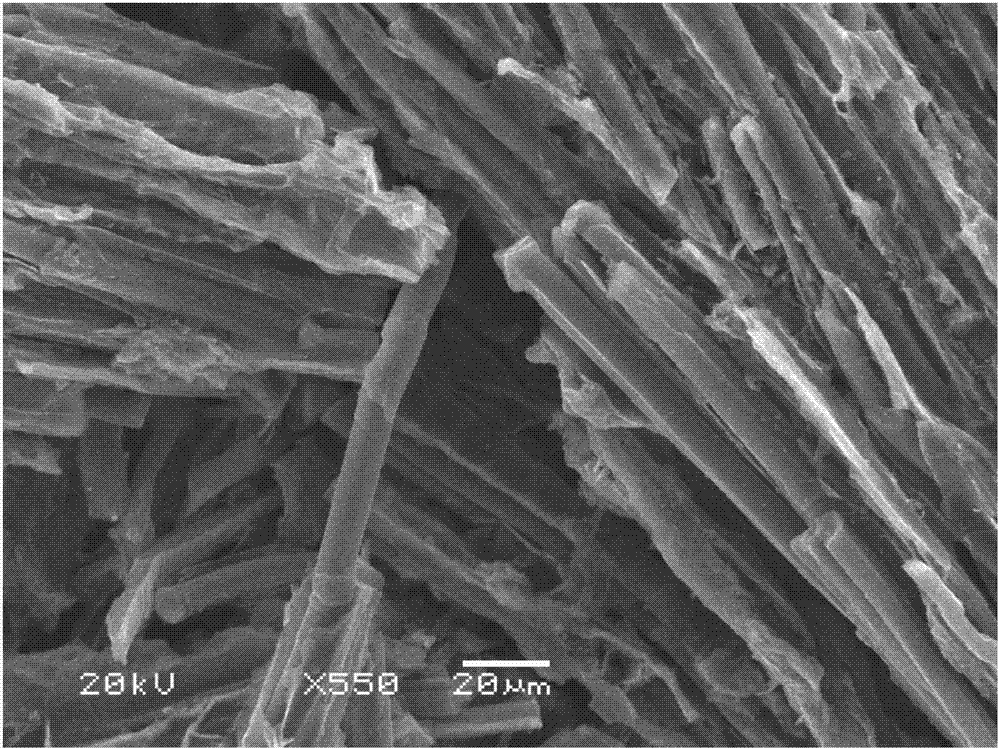

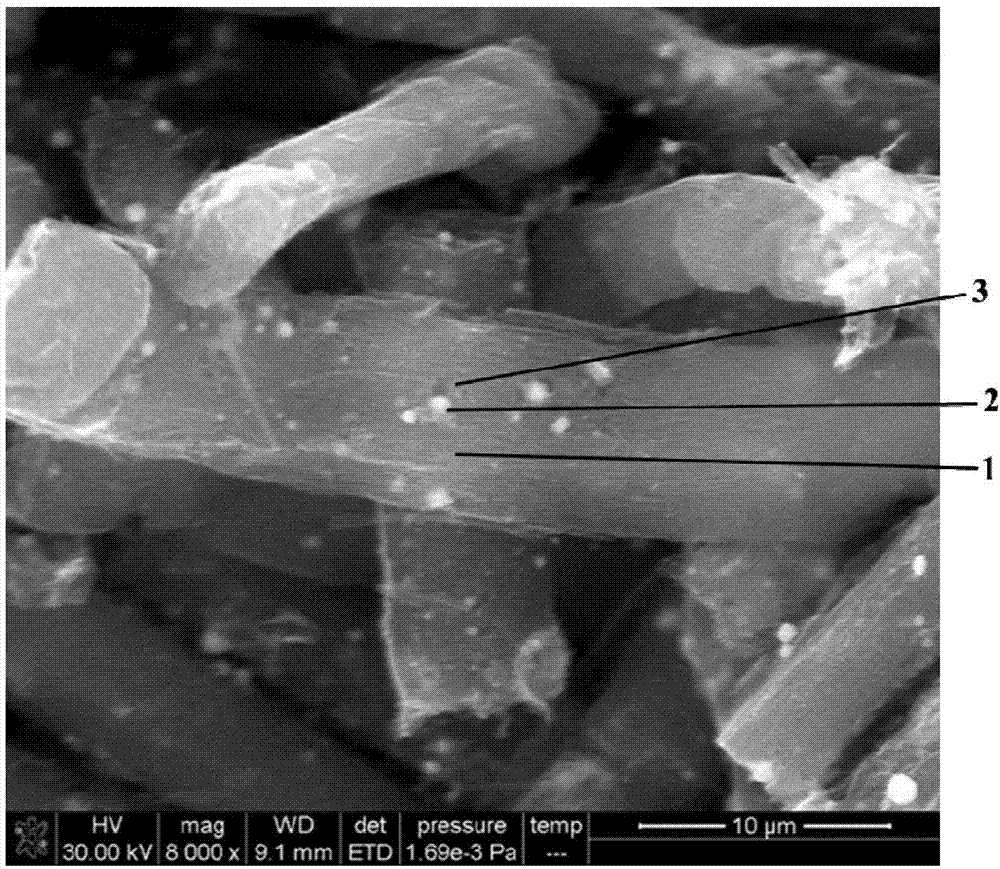

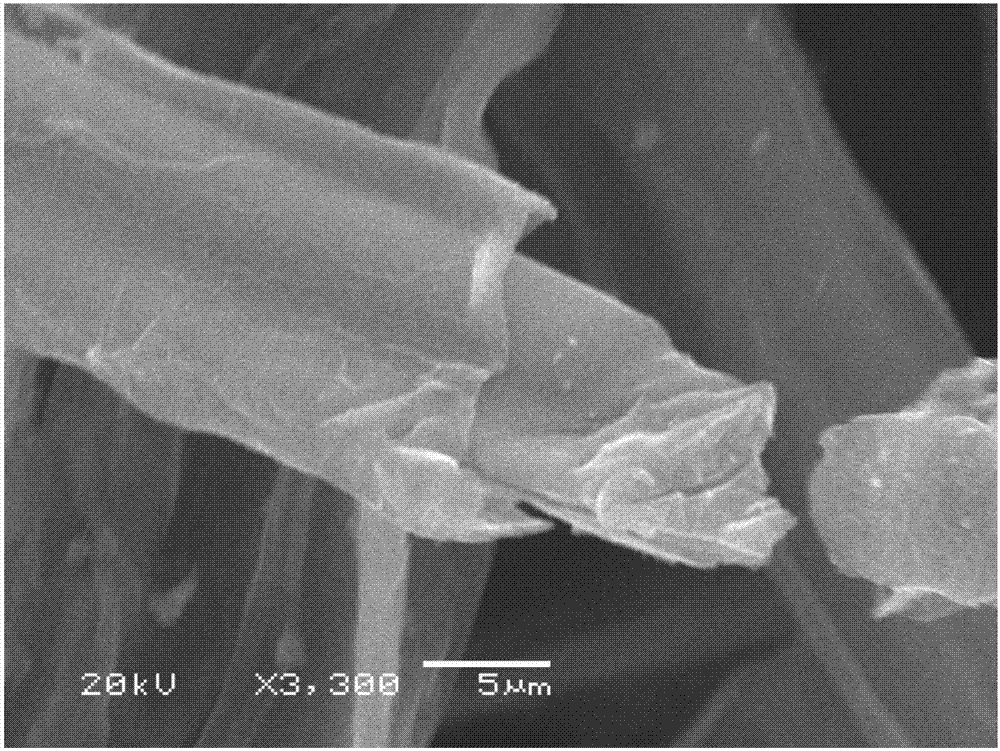

[0038]In this step, before carbonization and catalysis, the cellulose raw material is subjected to a beating and fiberizing process to regulate and control the carbon fiber material in which cellulose-based carbon fibers are closely packed with each other after carbonization and catalysis. figure 1 It is the SEM picture of the carbon fiber raw material obtained through the beating and fiberizing process. On the other hand, the morphology and tap density of the subsequently prepared cellulose-based carbon fiber electrode material can be adjusted through ...

Embodiment 2

[0053] Embodiment 2 of the present invention provides a method for preparing cellulose-based carbon fibers on the one hand, comprising the following steps:

[0054] S100. Preparation of cellulose raw materials: directly take cellulose-rich materials from plants as raw materials, wash the raw materials, boil them with alkali, beat them into fibers, wash them until they are neutral, and dry them to obtain cellulose raw materials;

[0055] S101. Preparing the precursor: dissolving the catalyst organic cobalt salt in water at a ratio of 0.5:1 to 0.01:1 by mass ratio between the organic cobalt salt and the cellulose raw material, adding the cellulose raw material, the mass of the water and the cellulose raw material The ratio is 1:1~50:1, heating to boiling and maintaining the boiling state, evaporating the water to dryness, and drying to obtain the precursor;

[0056] S102. Carbonization catalytic graphitization treatment: the precursor is calcined, carbonized, and catalytically g...

Embodiment 3

[0065] Embodiment 3 of the present invention provides a method for preparing cellulose-based carbon fibers, comprising the following steps:

[0066] S100. Preparation of cellulose raw materials: directly take cellulose-rich materials from plants as raw materials, wash the raw materials, boil them with alkali, beat them into fibers, wash them until they are neutral, and dry them to obtain cellulose raw materials;

[0067] S101. Preparing the precursor: dissolving the catalyst organic nickel salt in water at a ratio of 0.5:1 to 0.01:1 by mass ratio of the organic nickel salt to the cellulose raw material, adding the cellulose raw material, and the mass ratio of the water to the cellulose raw material is 1:1~50:1, heating to boiling and maintaining the boiling state, evaporating the water to dryness, and drying to obtain the precursor;

[0068] S102, Carbonization Catalytic Graphitization Treatment The precursor is roasted, carbonized, and catalytically graphitized under an inert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com