Multifunctional roadway repairing machine

A multi-functional roadway and repairing machine technology, applied in tunnels, slitting machinery, propulsion and other directions, can solve the problems of slow development of mechanization level, labor-intensive labor, time-consuming and labor-intensive, etc. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

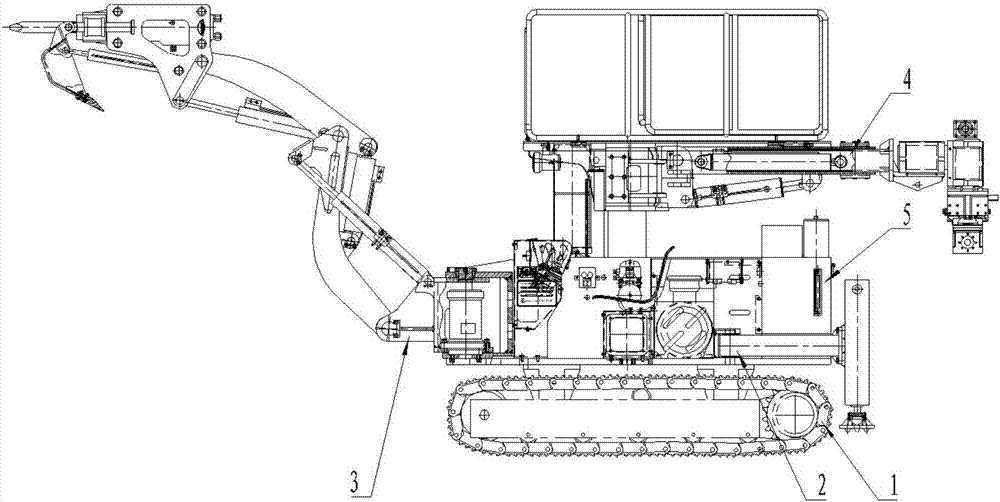

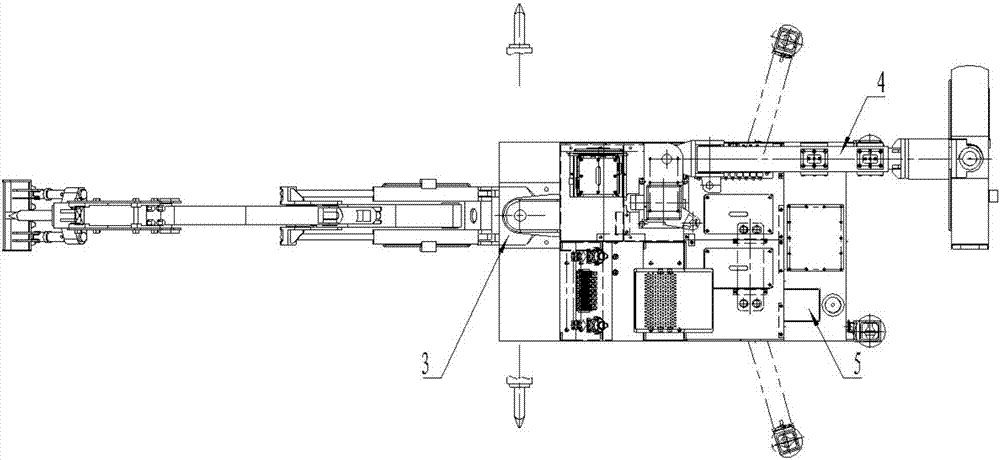

[0030] A multifunctional roadway repair machine, such as figure 1 and figure 2 Shown: including walking part 1, body part 2, cutting assembly 3, drill arm part 4 and hydraulic system 5, traveling mechanism 1 is set under the body part 2, cutting assembly 3 is set at the front end of the body part 2 , the drill arm part 4 is arranged on the right side of the body part 2, and the hydraulic system 5 is arranged at the tail end of the body part 2.

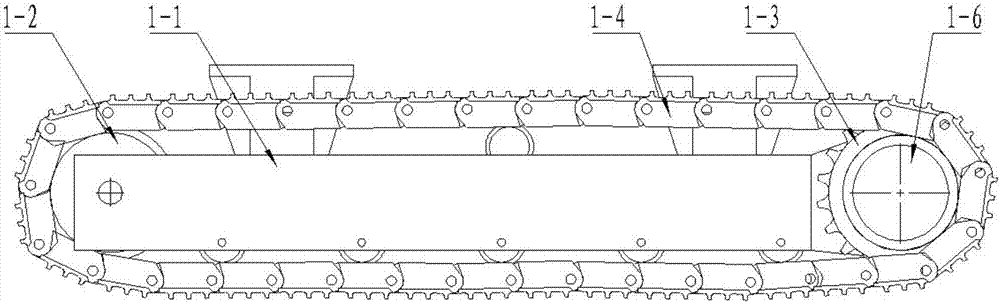

[0031] Such as image 3 and Figure 4As shown, the walking part 1 is composed of a crawler frame 1-1, a reversing sprocket 1-2, a drive sprocket 1-3, a crawler belt 1-4, a tensioning device 1-5, a reducer 1-6 and a traveling hydraulic pressure Composed of motor 1-7, two reversing sprockets 1-2 are arranged symmetrically on the left and right sides of the front end of the track frame 1-1, and two drive sprockets 1-3 are arranged on the left and right sides of the rear end of the track frame 1-1 The two sides are symmetrically distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com