Hybrid Multifunctional DC High Current Ice Melting Device

A DC ice-melting, multi-functional technology, applied in the direction of circuit devices, cable installation, harmonic reduction devices, etc., can solve the problems of inability to melt ice in transmission lines, waste of electric energy, and consumption of tens of thousands to hundreds of thousands of kWh. The effect of wide application range and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below, but the present invention is not limited to the following examples.

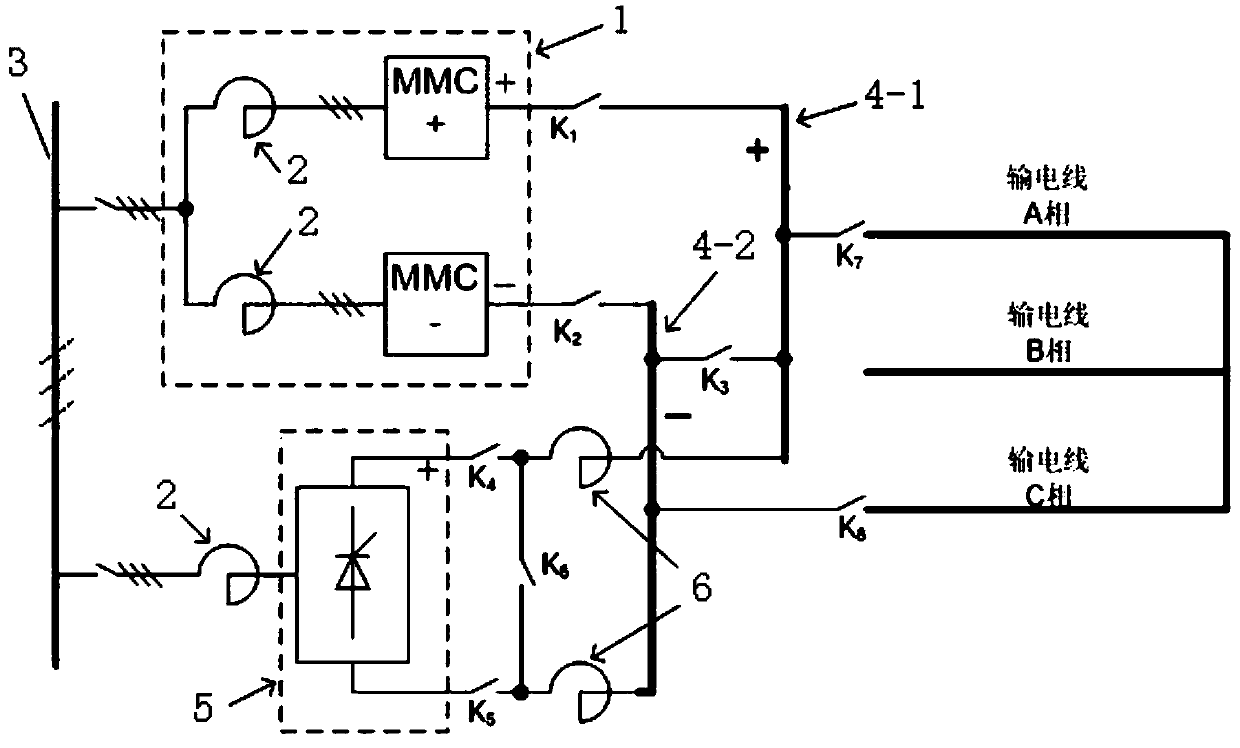

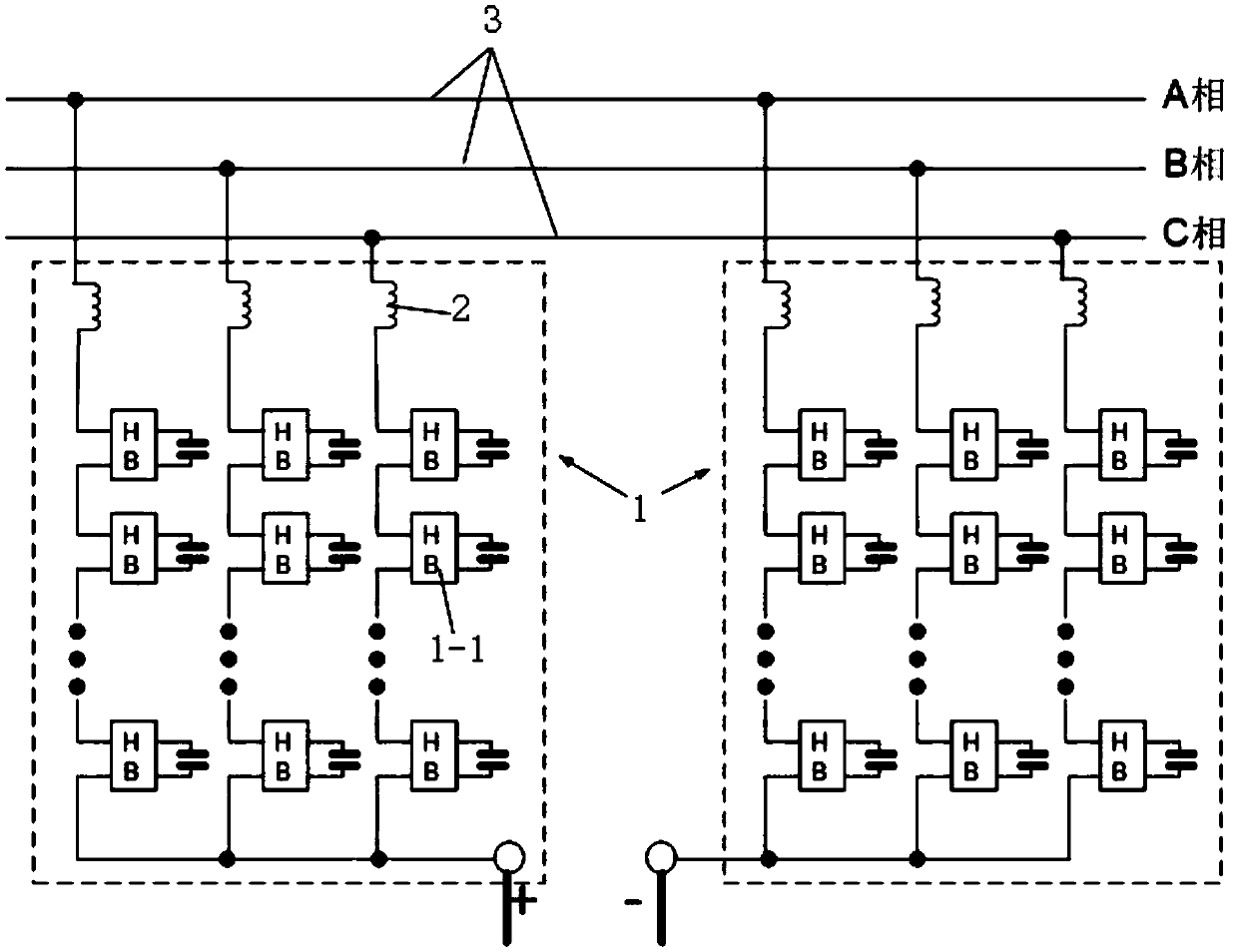

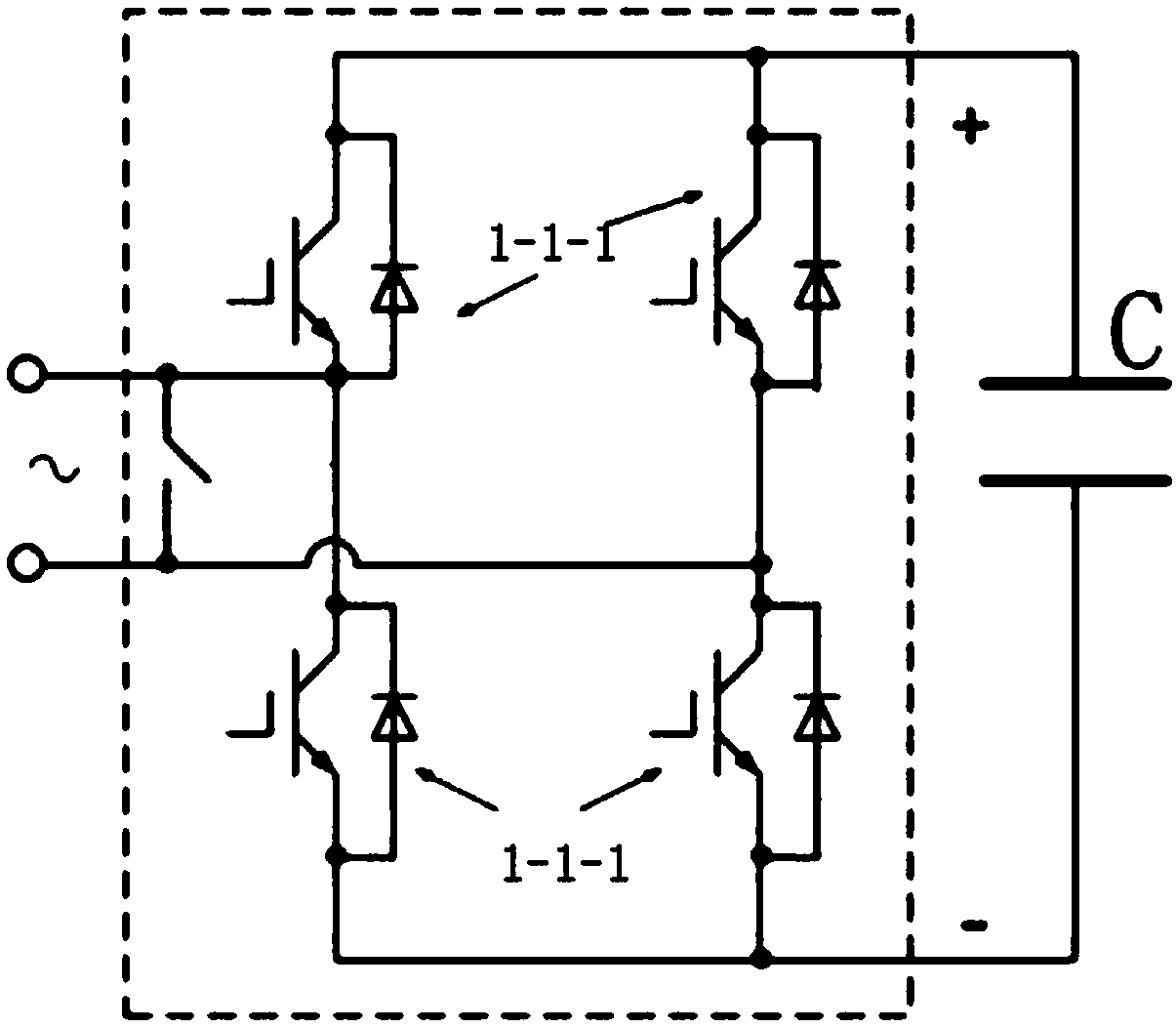

[0019] Such as figure 1 As shown, the present invention's "hybrid multi-functional direct current high-current deicing device" includes: a full-bridge MMC converter 1, a thyristor-type direct current deicing device 5, a group of DC smoothing reactors 6 and a group of knife switches K1~K8. The AC side of the full-bridge MMC converter and the AC side of the thyristor-type DC ice-melting device are respectively connected to the three-phase AC busbar 3 of the power supply. The positive pole of the DC side of the thyristor type DC ice melting device is connected to the positive DC bus 4-1 through the knife switch K4 and the DC smoothing reactor, and the negative pole of the DC side of the thyristor type DC ice melting device is passed through the knife switch K5 and the DC smoothing reactor Connect to the negative DC bus 4-2. The positive pole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com