Fermentation technology of fermented Pu'er tea

A fermentation process and technology of Pu-erh tea, applied in tea treatment before extraction, etc., can solve the problems of not being able to find out the uniformity of humidity of tea leaves in time, easily broken tea leaves, and unpleasant smells, so as to increase the cooked tea market, increase economic value, The effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

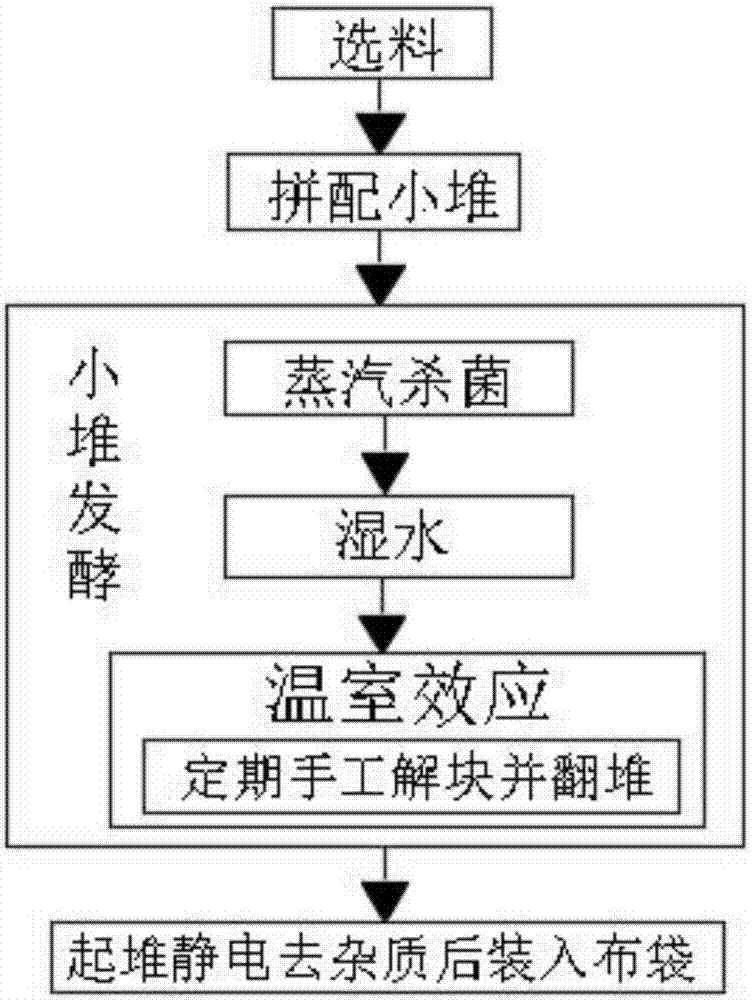

[0037] like figure 1 Shown, the present invention comprises following processing steps:

[0038] Step 1, material selection. The selected Yunnan big-leaf sun-dried green tea is withered, greened, kneaded and dried. The kneading must be heavy kneading. Heavy kneading refers to breaking the cell wall and overflowing the tea juice so that it can Promote the transformation of the contained substances under the action of microorganisms; at the same time, the selected Yunnan big-leaf sun-dried green tea contains less than 12% moisture, and check the tightness and curl degree of Yunnan big-leaf sun-dried green tea, that is, The selected Yunnan big-leaf sun-dried green hair tea must be that the buds, leaves and stems of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com