Fermenting machine for tea leaves

A tea fermentation machine and tea technology, applied in the field of fermentation machines, can solve the problems affecting the quality of tea fermentation, uneven exposure to oxygen, high temperature and humidity, etc., and achieve the effects of uniform heating, quality assurance, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

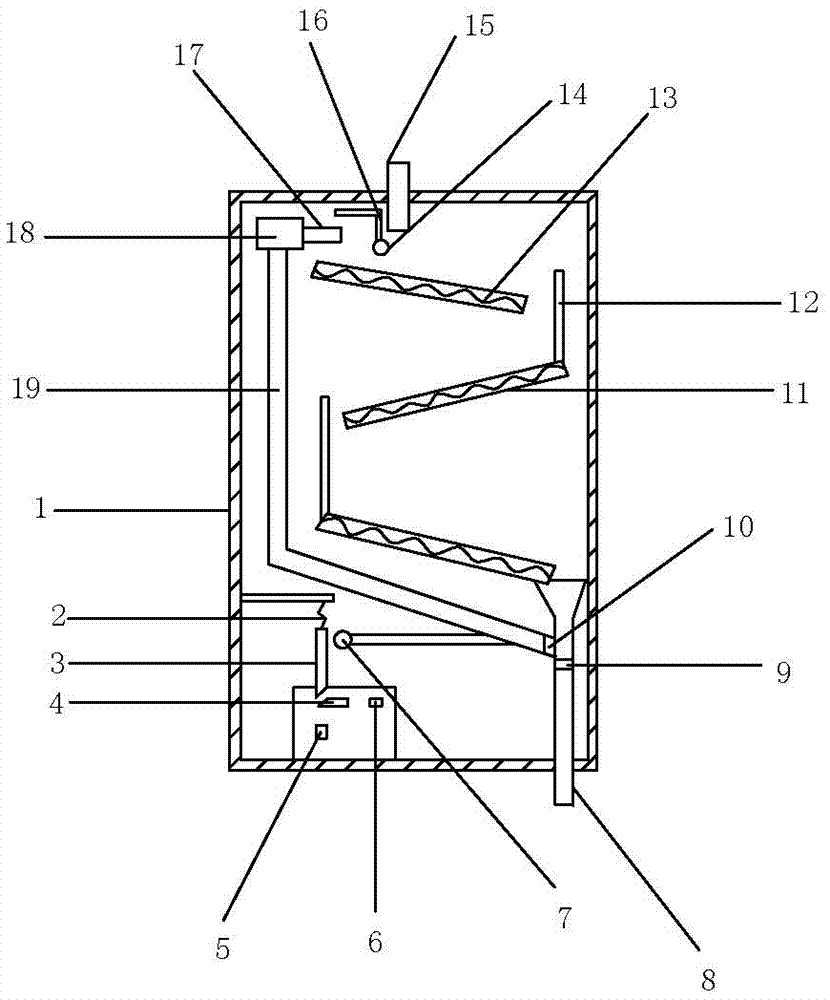

Embodiment 1

[0026] Such as figure 1 As shown, the tea fermentation machine of the present invention includes a box body 1, and three layers of slide plates 11 are obliquely welded inside the box body 1, and the inclination directions of two adjacent slide plates 11 are opposite. Wherein, the box body above the high end of the uppermost slide plate 11 has a feed opening 15, and the box body below the low end of the bottom slide plate 11 has a discharge port 8, and the discharge port 8 communicates with the bottom slide plate 11. discharge pipe. The left side of the uppermost slide 11 is equipped with an air extractor 18 through a bolt, and the air outlet pipe 17 of the air extractor 18 is located above the uppermost slide 11. The right end of the air outlet pipe 17 is welded with a guide plate 16, and the bottom end of the guide plate 16 is rotatably connected. Lead ball 14 is arranged. The suction pipe 19 of the air extractor 18 is communicated with the discharge pipe, and the discharge...

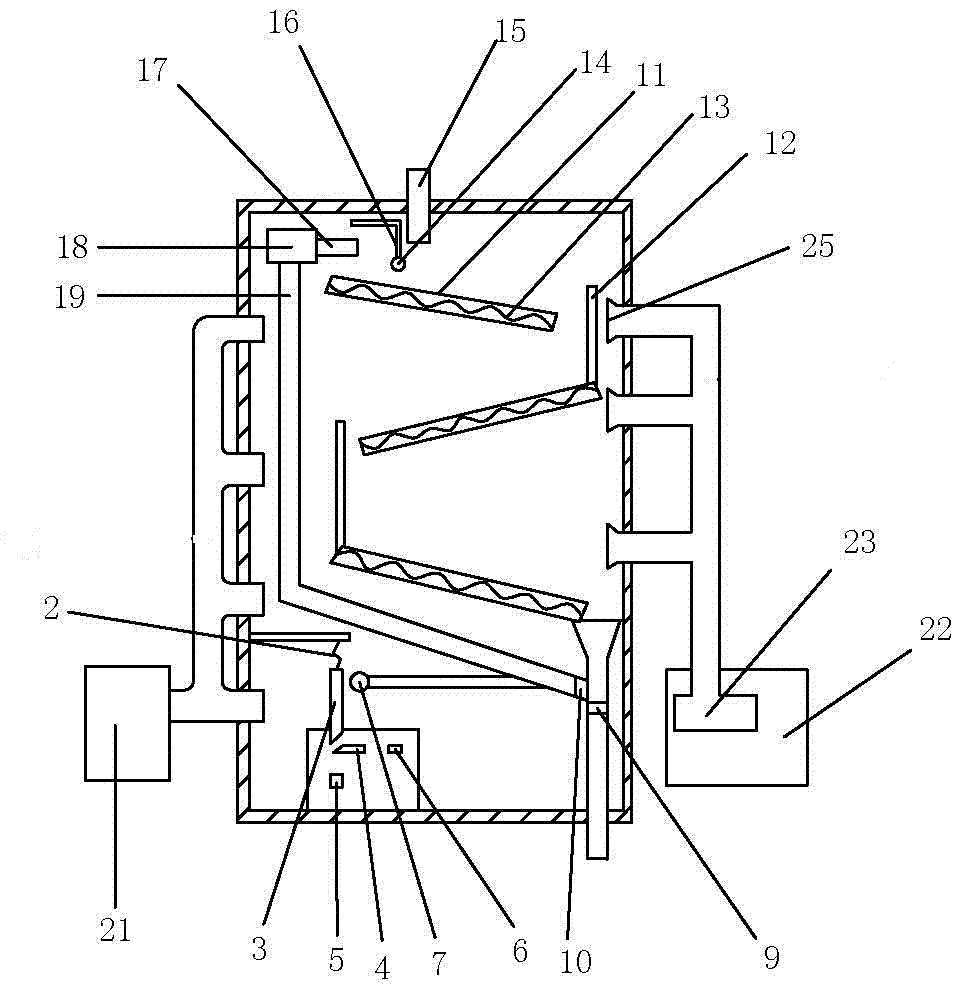

Embodiment 2

[0029] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a water tank 22 is installed on the right side of the box body 1, and an atomizer 23 is arranged in the water tank 22, and the atomizer 23 communicates with the spray head 25, and the spray The heads 25 are scattered and distributed in the casing 1 . An oxygen generator 21 is arranged on the left side of the box body 1 , and the oxygen generator 21 communicates with the box body 1 .

[0030] When it is necessary to transport oxygen and spray water to the tea leaves, the oxygen generator 21 and the atomizer 23 are started, and oxygen is injected into the cabinet 1 through the oxygen tubes 20. The arrangement of multiple oxygen tubes 20 increases the contact surface between the tea leaves and oxygen. The spray head 25 sprays the atomized water onto the tea leaves, and the sliding of the tea leaves makes the tea leaves evenly contact with the moisture.

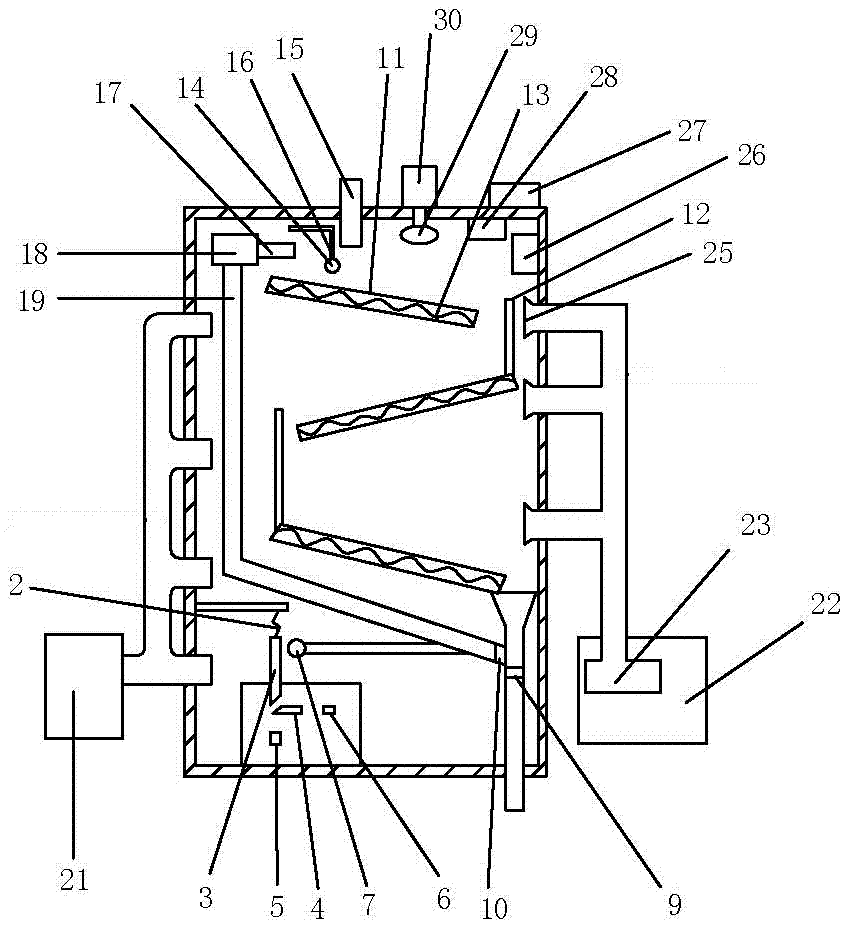

Embodiment 3

[0032] Such as image 3As shown, the difference between the present embodiment and the second embodiment is that the enzyme spray head 29 is rotatably connected to the box above the slide plate 11 , and the enzyme spray head 29 communicates with the enzyme storage box 30 outside the box 1 . Humidity sensor 28 and temperature sensor 26 are installed in the casing 1, and main control box 27 is installed outside casing 1, and this main control box 27 is electrically connected with humidity sensor 28 and temperature sensor 26, and main control box 27 is installed in The display screen (not shown in the figure) outside the box body 1 is electrically connected.

[0033] The humidity sensor 28 and the temperature sensor 26 are used to detect the humidity and temperature in the casing 1 respectively, and the detected signal is sent to the main control box 27 for processing, and the main control box 27 transmits the processed signal to the display screen for further processing. show. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap