Plant nourishing shampoo, preparation method of extract of plant nourishing shampoo and preparation method of plant nourishing shampoo

A technology of shampoo and extract, which is applied in the field of shampoo, can solve the problems of large dust and oil stains, narrow work site space, clogged hair follicles, etc., achieve good lubricity, good cleaning effect, and eliminate the effects of hard water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

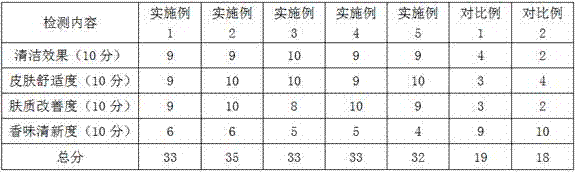

Examples

Embodiment 1

[0045]A plant moisturizing shampoo and its extract preparation method and its preparation method, the shampoo is composed of the following raw materials in parts by weight: 0.5 parts of disodium edetate, 25 parts of sodium laureth sulfate, 6 parts of sodium cocoyl glycinate, 4 parts of sodium methyl cocoyl taurate, 3 parts of butylene glycol, 0.3 parts of xanthan gum, 0.3 parts of citric acid, 0.01 part of methylisothiazolinone, cocoamidopropyl Betaine 25 parts, Polyquaternium-10 0.6 parts, Guar Gum Hydroxypropyltrimonium Chloride 0.6 parts, Mela Aubinia Palm Kernel Oil 1 part, Hydrogenated Soybean Oil 1 part, Coconut Oil 1 part 1 part of linseed oil, 1 part of tocopherol, 4 parts of cocoamide monoethanolamine, 3 parts of ethylene glycol distearate, 0.5 part of phenoxyethanol, 1 part of Polygonum multiflorum root extract, grapefruit seed extract 1 part, 1 part of black sesame extract, 100 parts of deionized water;

[0046] The extract preparation method comprises the followin...

Embodiment 2

[0060] Its difference with embodiment 1 is:

[0061] 0.7 parts of disodium edetate, 7 parts of sodium cocoyl glycinate, 5 parts of sodium methyl cocoyl taurate, 4 parts of butylene glycol, 0.4 parts of xanthan gum, 0.4 parts of citric acid, methyl iso Thiazolone 0.02 part, Polyquaternium-10 0.7 part, Guar Gum Hydroxypropyltrimonium Chloride 0.7 part, Mela Aubinia Palm Kernel Oil 2 parts, Hydrogenated Soybean Oil 2 parts, Coconut Oil 2 parts 2 parts, linseed oil, 2 parts tocopherol, 5 parts cocoyl monoethanolamine, 4 parts ethylene glycol distearate, 0.5 parts phenoxyethanol, 2 parts Polygonum multiflorum root extract, grapefruit seed extract 2 parts, black sesame extract 2 parts.

Embodiment 3

[0063] Its difference with embodiment 1 is:

[0064] 1 part of disodium EDTA, 28 parts of sodium laureth sulfate, 8 parts of sodium cocoyl glycinate, 5 parts of sodium methyl cocoyl taurate, 4 parts of butylene glycol, 0.4 parts of xanthan gum 0.4 parts of citric acid, 0.02 parts of methylisothiazolinone, 0.8 parts of polyquaternium-10, 0.8 parts of guar gum hydroxypropyltrimonium chloride, 2 parts of beautiful Aubinha palm kernel oil , 2 parts hydrogenated soybean oil, 2 parts coconut oil, 2 parts linseed oil, 2 parts tocopherol, 5 parts cocamide monoethanolamine, 3 parts ethylene glycol distearate, 1 part phenoxyethanol, Polygonum multiflorum root Extract 3 parts, grapefruit seed extract 2 parts, black sesame extract 3 parts, deionized water 150 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com