Chinese yam polysaccharide extracting method

An extraction method, a technology of yam polysaccharides, applied in the field of extraction of yam polysaccharides, can solve the problems of low extraction rate, short extraction time, and large power consumption, and achieve the effects of optimizing extraction conditions, simplifying extraction process, and improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

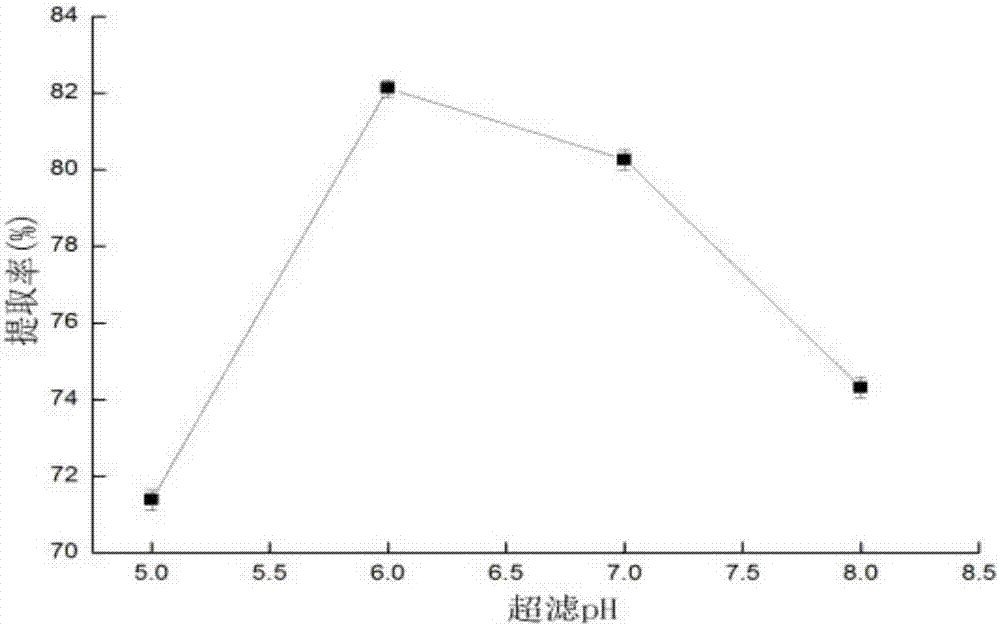

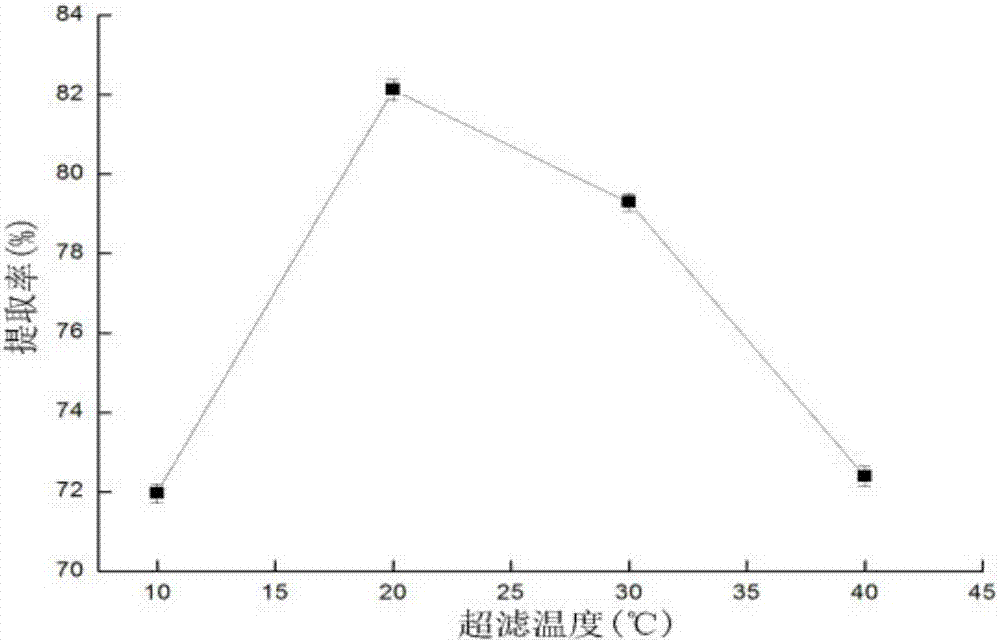

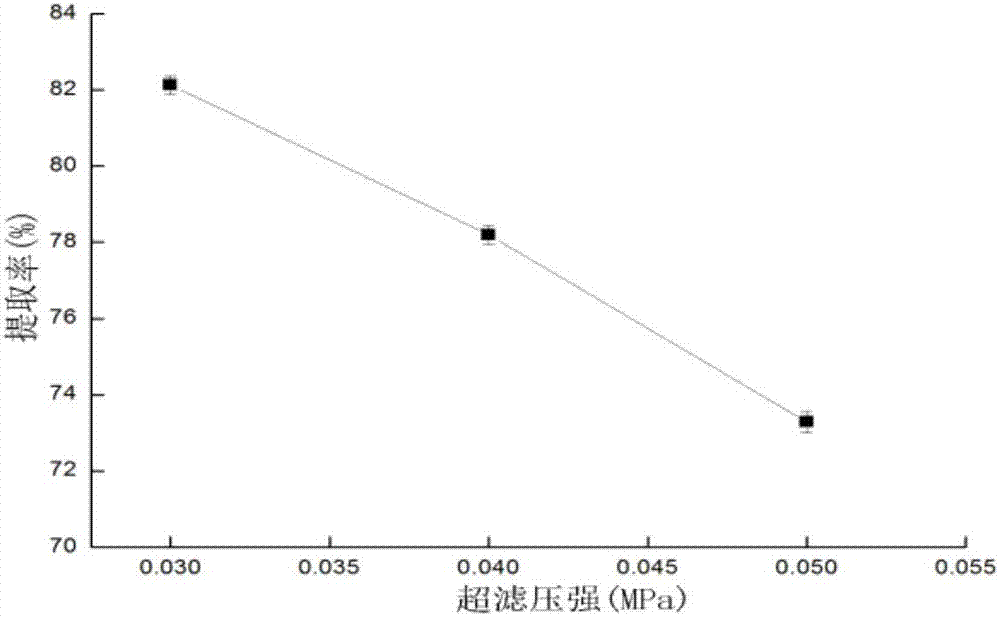

[0039] Example 1: Determination of suitable working conditions for extracting yam polysaccharides by ultrafiltration

[0040] 1. Operation process

[0041] 1) Accurately weigh 500g of whole fresh yam, peel and cut into pieces.

[0042] 2) Add 1000ml of 1% sodium bisulfite solution with pH=8.5 according to the ratio of material to liquid (g / ml) of 1:2, and perform beating to obtain yam homogenate.

[0043] 3) The yam homogenate was centrifuged at 6000 rpm and 4°C for 20 min.

[0044] 4) Filter the supernatant to remove starch.

[0045] 5) Take the filtrate to adjust the pH=3.5, and stir it magnetically for 1 hour to obtain a suspension.

[0046] 6) Centrifuge the suspension at 6000 rpm and 4°C for 20 min to precipitate yam protein.

[0047] 7) Adjust the ultrafiltration pH of the centrifuged supernatant to a certain value, adjust the ultrafiltration pressure to a certain value, adjust the ultrafiltration temperature to a certain value, and use an ultrafiltration membrane wi...

Embodiment 2

[0060]Example 2: Response surface optimization and analysis of ultrafiltration extraction of yam polysaccharides

[0061] Design-Expert 8.0.6 software was used in the experiment for response surface design and result analysis.

[0062] (1) Experimental design results

[0063] Table 2 Results of Box-Behnken experimental design

[0064]

[0065]

[0066] (2) Regression model analysis of variance

[0067] Table 3 Regression model analysis of variance of response surface test

[0068]

[0069] In order to check the variables, ultrafiltration pH value (A), ultrafiltration temperature (B), and ultrafiltration pressure (C), the impact on the extraction rate, the Box-Behnken test design was used, and the test results are shown in Table 3. By applying multiple regression to analyze the experimental data, predict the reaction Y (extraction rate of polysaccharide) to obtain the following equation:

[0070] R 1 =39.788-2.22A+2.75B-1.44C-1.08AB+1.37AC+1.41BC-3.47A 2 +0.24B ...

Embodiment 3

[0076] Embodiment 3: the mensuration of Chinese yam polysaccharide composition

[0077] The composition of yam polysaccharide samples measured by the national standard method is shown in Table 4. The polysaccharide content is 43.84%, the protein content is 18.52%, the crude fat content is 2.52%, the crude fiber content is 1.28%, the moisture content is 9.62%, and the ash content is 4.28%.

[0078] Table 4 Polysaccharide Composition Table

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com