Waterborne knurling assistant suitable for synthetic leather

A synthetic leather, water-based technology, applied in the direction of coating, textiles and papermaking, etc., can solve the problems of poor embossing effect, etc., to achieve the effect of ensuring integrity and aesthetics, prominent pattern lines, and clear pattern lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 0.5 parts of N-vinylpyrrolidone and 0.05 parts of vinyl ferrocene to 3 parts of polyvinyl alcohol resin, and heat up to 115-120 ° C at a heating rate of 5 ° C / min for 30 minutes, and then mix for 10 The cooling rate of °C / min is lowered to 70-80 °C, then 2 parts of hydrogenated palm oil and 0.3 part of molecular sieve powder are added, and then mixed at 70-80 °C for 15 minutes to obtain material I;

[0025] (2) Add 1 part of disodium lauryl sulfosuccinate and 0.5 part of polyepoxysuccinic acid to 25 parts of 50 wt% modified terpene resin emulsion, and heat up to reflux state at a heating rate of 5 °C / min Mixed for 15min, then naturally cooled to room temperature to obtain material II;

[0026] (3) Add 5 parts of nano-titanium dioxide modified poloxamer and 2 parts of pregelatinized tapioca starch to 100 parts of water, stir to make it completely dissolve and let it stand for 30 minutes, then add material I, material II and 0.2 part of tetraglycine , fully mix...

Embodiment 2

[0030] (1) Add 0.5 parts of N-vinylpyrrolidone and 0.05 parts of vinyl ferrocene to 3 parts of polyvinyl alcohol resin, and heat up to 115-120 ° C at a heating rate of 5 ° C / min for 30 minutes, and then mix for 10 ℃ / min cooling rate to 70-80 ℃, add 1 part of hydrogenated palm oil and 0.3 part of molecular sieve powder, and then mix at 70-80 ℃ for 15 minutes to obtain material I;

[0031] (2) Add 1 part of disodium lauryl sulfosuccinate and 0.5 part of polyepoxysuccinic acid to 25 parts of 50 wt% modified terpene resin emulsion, and heat up to reflux state at a heating rate of 5 °C / min Mixed for 15min, then naturally cooled to room temperature to obtain material II;

[0032] (3) Add 3 parts of nano-titanium dioxide modified poloxamer and 2 parts of pregelatinized tapioca starch to 100 parts of water, stir to make it completely dissolve and let it stand for 30 minutes, then add material I, material II and 0.2 part of tetraglycine , fully mixed and then sent to a ball mill for...

Embodiment 3

[0047] Add the water-based embossing assistant made in the same amount of Example 1, Example 2, Comparative Example 1 and Comparative Example 2 to the water-based polyurethane slurry (as shown in Table 1), and set the contrast without adding the water-based embossing assistant Example 3: Synthetic leather products were produced through the same processing technology, and their embossing effects were compared. The results are shown in Table 2.

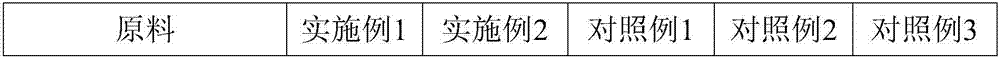

[0048] Table 1 Waterborne polyurethane slurry formulation

[0049]

[0050]

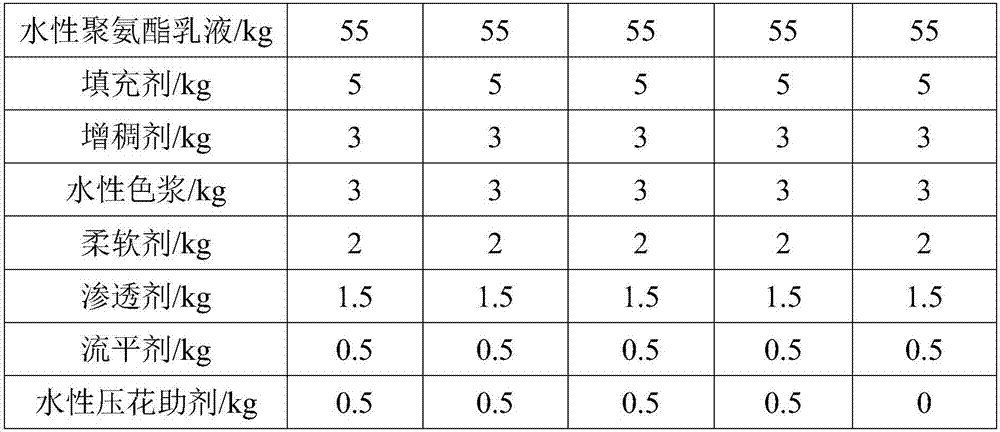

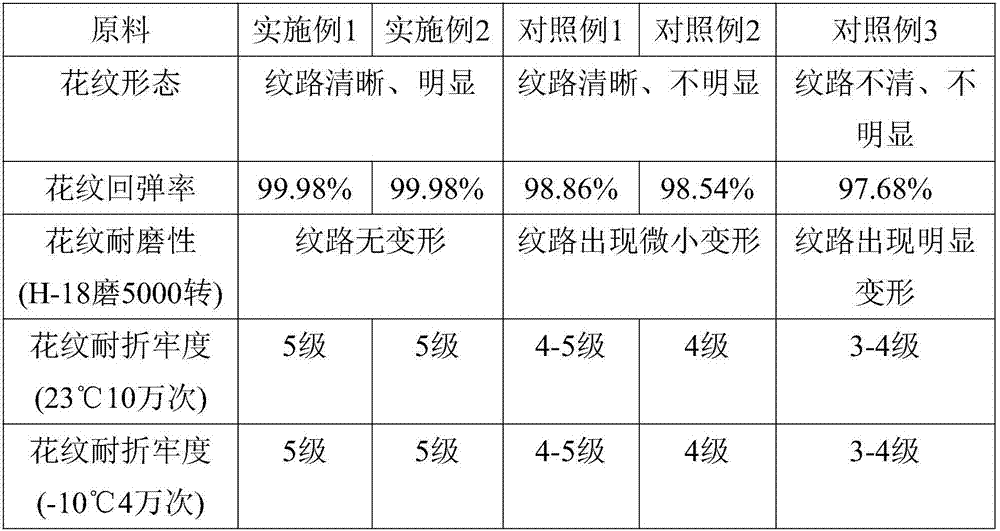

[0051] Table 2 Embossing effect of synthetic leather products

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com