Method for preparing peach kernel extract for cigarette by immobilized lactic acid bacteria

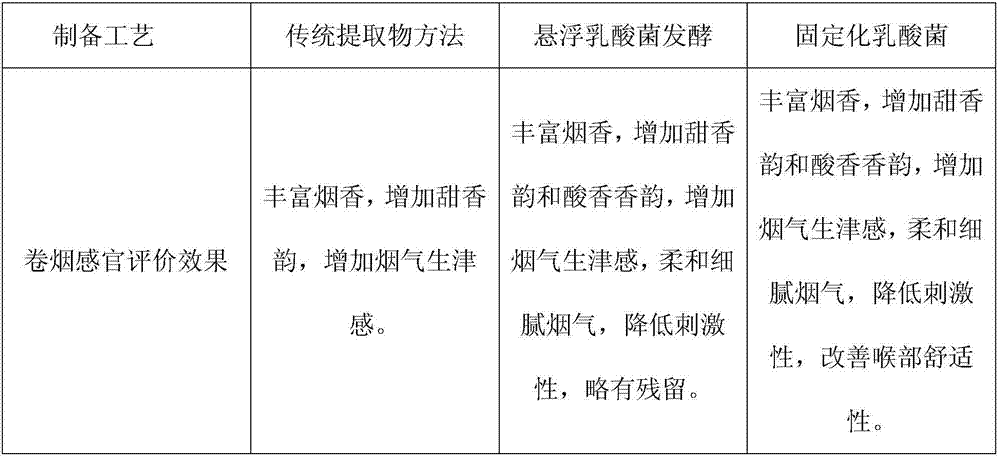

A technology of lactic acid bacteria and extracts, which is applied in the field of preparation of peach kernel extracts for tobacco use, to achieve the effects of improving throat comfort, high efficiency, and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a kind of method that immobilized lactic acid bacteria prepares the peach kernel extract for tobacco use comprises the following steps:

[0023] (1) Add 2 times of water by weight to the peach kernel, soak for 12 hours, reflux and extract twice at 100°C, each extraction time is 6 hours, cool to room temperature after extraction, and filter to obtain the extract, combine the two Extracting solution for the second time, obtaining peach kernel extract A, the conditions of twice extraction are exactly the same;

[0024] (2) Mix the peach kernel extract A with the PVA-SA immobilized lactic acid bacteria pellets prepared by the above method according to the mass ratio of 5:1, ferment for 4 days at a temperature of 30°C and a stirring speed of 5rpm, and then place at 4°C Store in the freezer for 8 days;

[0025] (3) filter the fermented liquid after step (2) fermentation to obtain clarified fermented liquid, and freeze-dry the fermented liquid, the thickness of ...

Embodiment 2

[0028] Embodiment 2, a kind of method that immobilized lactic acid bacteria prepares the peach kernel extract for tobacco use comprises the following steps:

[0029](1) Take peach kernels, add 5 times its weight in water, soak for 16 hours, then reflux extraction at 98°C for 3 times, each extraction time is 8 hours, cool to room temperature after extraction, and filter to obtain the extract, combine Extracting liquid three times to obtain peach kernel extract A; the conditions of three extractions are exactly the same;

[0030] (2) Mix peach kernel extract A with the PVA-SA immobilized lactic acid bacteria pellets prepared in the above method according to the mass ratio of 8:1, and ferment for 5 days at a temperature of 35°C and a stirring speed of 3rpm, and then Store in a 4°C freezer for 9 days;

[0031] (3) filter the fermented liquid after step (2) to obtain clarified fermented liquid, and freeze-dry the fermented liquid, the thickness of the feed liquid is 1-2 cm, the va...

Embodiment 3

[0034] Embodiment 3, a kind of method that immobilized lactic acid bacteria prepares the peach kernel extract for tobacco use comprises the following steps:

[0035] (1) Take peach kernels, add 3 times its weight in water, soak for 24 hours, then reflux extraction at 95°C for 3 times, each extraction time is 6 hours, cool to room temperature after extraction, and filter to obtain the extract, combine Three times of extracting solution to obtain peach kernel extract A; three times of extraction conditions are exactly the same;

[0036] (2) Mix the peach kernel extract A with the PVA-SA immobilized lactic acid bacteria pellets prepared by the above method at a mass ratio of 10:1, ferment for 3 days at a temperature of 37°C and a stirring speed of 2rpm, and then place at 4°C Store in the freezer for 14 days;

[0037] (3) filtering the fermented liquid after fermentation in step (2) to obtain a clarified fermented liquid, and freeze-drying the fermented liquid, the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com