Two-step pyrolysis and gasification furnace for recycling domestic garbage

A technology of pyrolysis and gasification of domestic waste, applied in the direction of incinerators, gasification processes, combustion methods, etc., can solve the problems of secondary pollution, inability to realize the utilization of thermal energy resources, etc., and achieve sufficient combustion, simple structure, and high temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

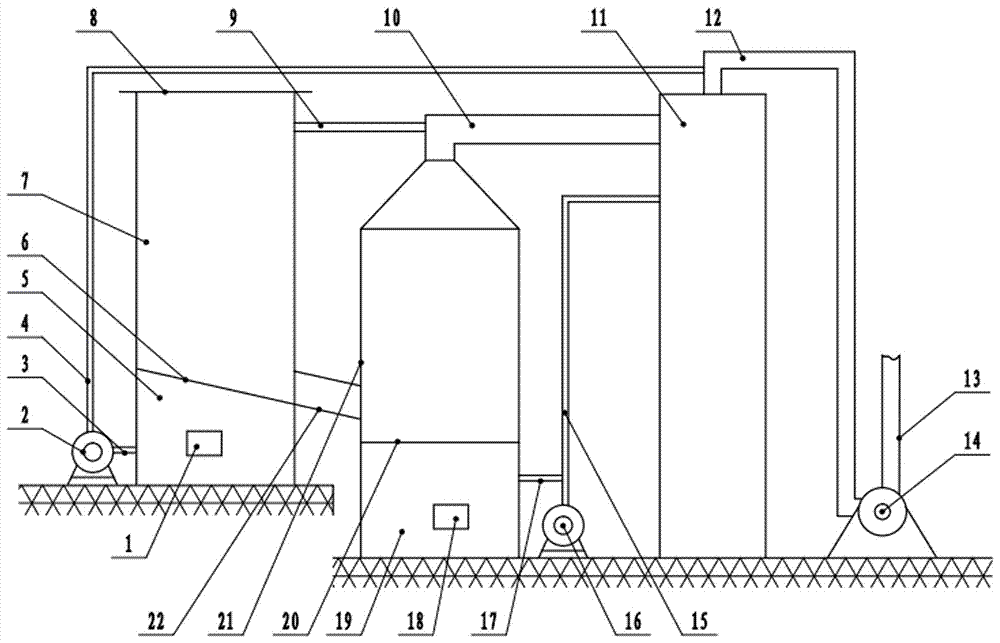

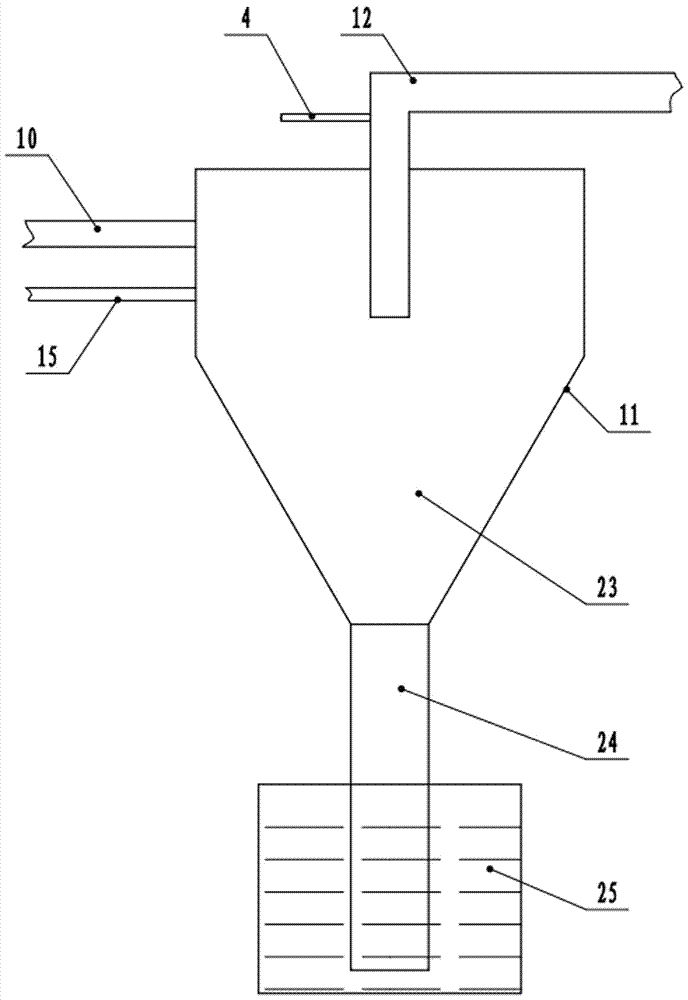

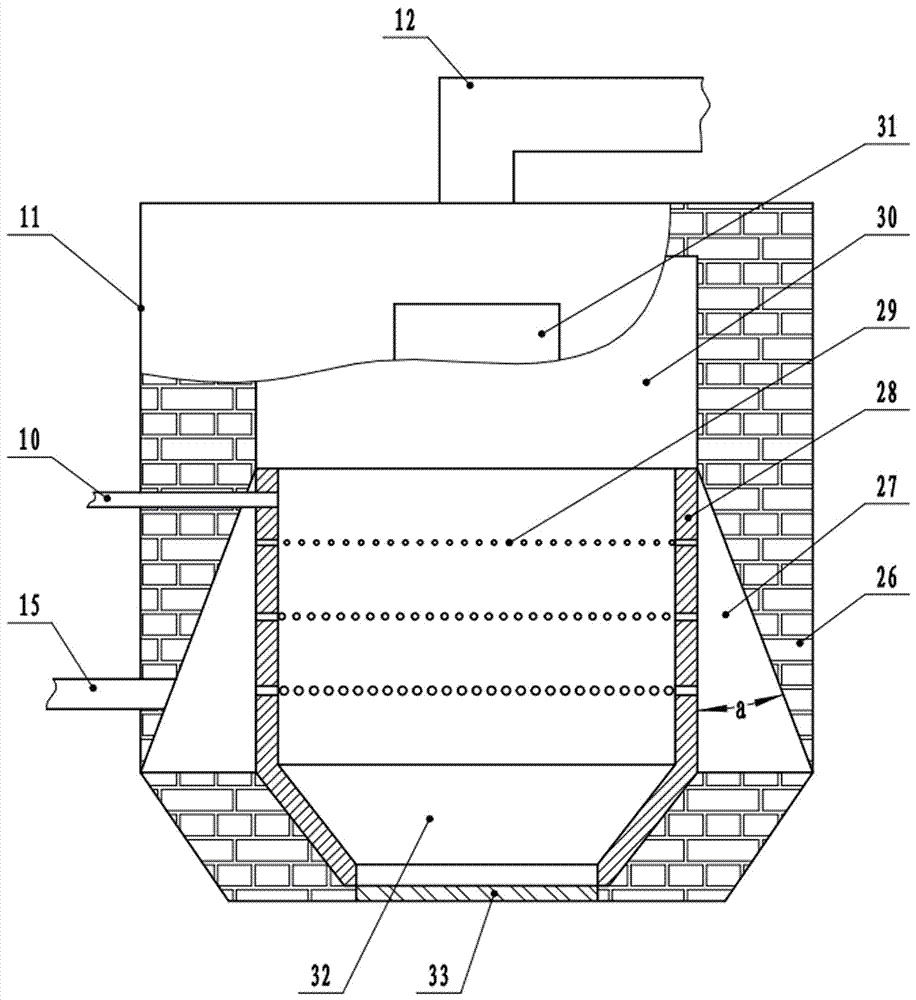

[0024] The domestic waste pyrolysis gasification furnace of the two-step method of resource utilization includes a primary gasification furnace 7, a combustion furnace 11 and a secondary gasification furnace 21. The top of the primary gasification furnace 7 is provided with a furnace cover 8, and a The lower part of the primary gasifier 7 is provided with a primary grate 6, and below the primary grate 6 is a primary ash hopper chamber 5, and the primary ash hopper chamber 5 is provided with a primary ash outlet 1; The lower part is provided with a secondary fire grate 20, and below the secondary fire grate 20 is a secondary ash hopper chamber 19. The secondary ash hopper chamber 19 is provided with a secondary ash outlet 18, and the top of the secondary gasifier 21 passes through the mixed flue gas pipe 10 It is connected to the combustion chamber of the combustion furnace 11; the mixed flue gas pipe 10 is connected to the upper part of the first-stage gasification furnace 7 th...

Embodiment 2

[0027]The domestic waste pyrolysis gasification furnace of the two-step method of resource utilization includes a primary gasification furnace 7, a combustion furnace 11 and a secondary gasification furnace 21. The top of the primary gasification furnace 7 is provided with a furnace cover 8, and a The lower part of the primary gasifier 7 is provided with a primary grate 6, and below the primary grate 6 is a primary ash hopper chamber 5, and the primary ash hopper chamber 5 is provided with a primary ash outlet 1; The lower part is provided with a secondary fire grate 20, and below the secondary fire grate 20 is a secondary ash hopper chamber 19. The secondary ash hopper chamber 19 is provided with a secondary ash outlet 18, and the top of the secondary gasifier 21 passes through the mixed flue gas pipe 10 It is connected to the combustion chamber of the combustion furnace 11; the mixed flue gas pipe 10 is connected to the upper part of the first-stage gasification furnace 7 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com