Sealing frame for sealing liquid metal, application, integrated heat dissipation structure, and electronic element

An electronic component and liquid metal technology, applied in electrical components, electric solid devices, semiconductor devices, etc., can solve problems such as liquid metal leakage, achieve the effect of strengthening rigidity, simple three-layer structure, and avoiding glue leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

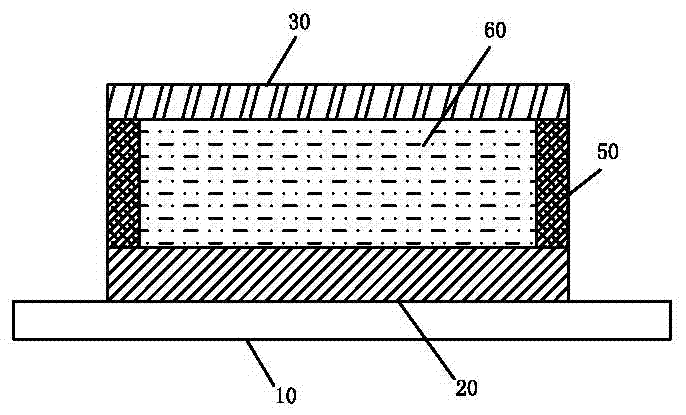

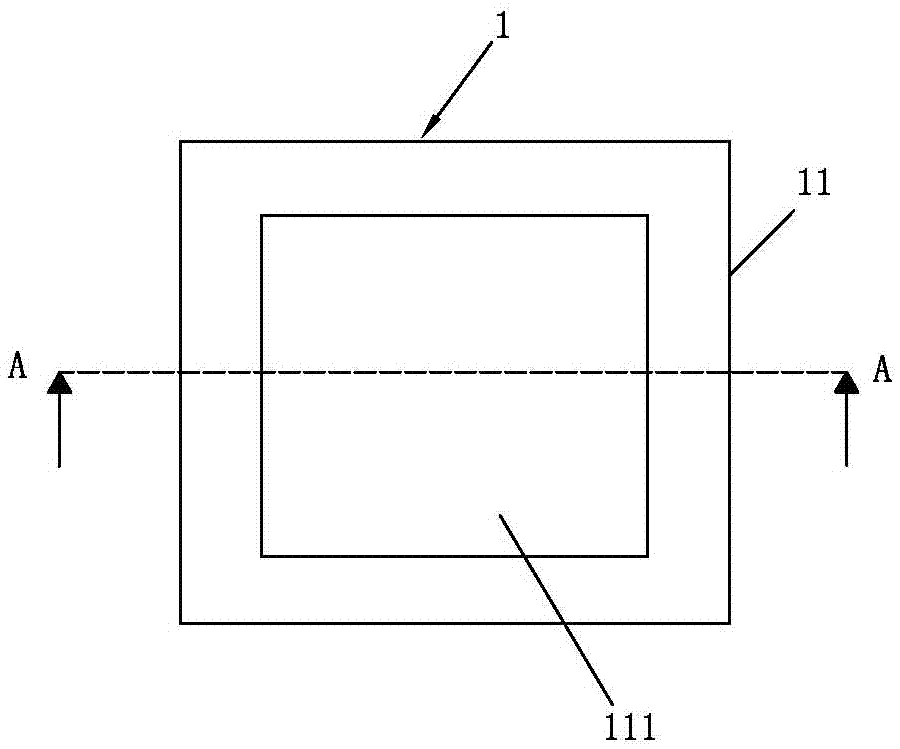

[0037] Integrated heat dissipation structure for sealing liquid metal, such as Figure 3 to Figure 5As shown, it includes a liquid metal 60 and a sealing frame 1 for sealing the liquid metal 60, wherein: the sealing frame 1 includes a frame body 11 that matches the shape of the heating element 20 and is provided on both surfaces of the frame body 11 with thermally conductive adhesive layers 12. The frame body is provided with a through hole 111. The liquid metal 60 is filled in the through hole 111 and formed integrally with the sealing frame 1 through a die-casting process. The liquid metal 60 is formed into a sheet-like liquid metal 60 through a die-casting process. The sheet-like liquid metal 60 The size of is consistent with the size of the through hole 111. When in use, one surface of the frame body 11 is bonded to the heating element 20 through the thermally conductive adhesive layer 12, and the other surface is bonded to the heat sink 30 through the thermally conductive...

Embodiment 2

[0057] An electronic component such as Image 6 As shown, it includes a substrate 10 , a heating element 20 disposed on the substrate 10 , and a heat sink 30 , and also includes an integrated heat dissipation structure for sealing the liquid metal 60 , which is exactly the same as that of Embodiment 1. Wherein, one surface of the sealing frame 1 is bonded to the heating element 20 through the thermally conductive adhesive layer 12 arranged on the surface, and the other surface of the sealing frame 1 is bonded to the heat sink 30 through the thermally conductive adhesive layer 12 arranged on the surface. , so that the liquid metal 60 is sealed in the accommodating space among the sealing frame 1 , the heating element 20 and the heat sink 30 . When in use, the two surfaces of the sealing frame 1 are directly bonded to the heating element 20 and the radiator respectively through the heat-conducting adhesive layer 12. When the electronic components work, the heating element 20 gen...

Embodiment 3

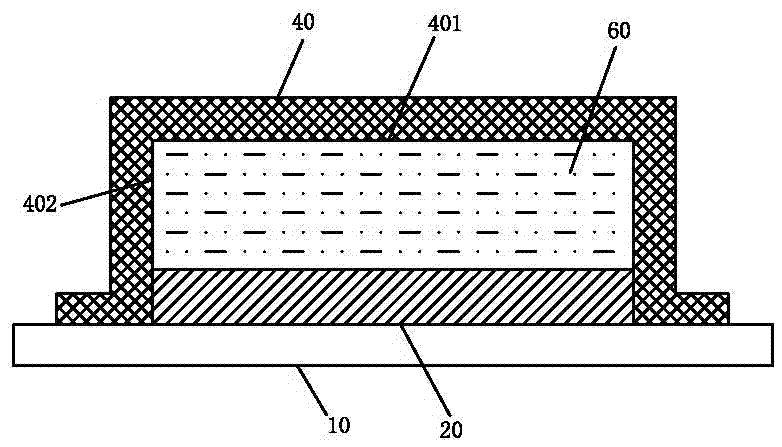

[0059] The main technical scheme of the present embodiment is the same as that of embodiment 2, the difference is:

[0060] An electronic component such as Figure 7 As shown, the heat dissipation device includes a shielding cover 40, one surface of the sealing frame 1 is bonded to the heating element 20 through the thermally conductive adhesive layer 12 arranged on the surface, and the other surface of the sealing frame 1 is bonded to the heating element 20 through the thermally conductive adhesive layer arranged on the surface. The layer 12 is bonded to the bottom wall of the U-shaped groove of the shielding case 40, so that the liquid metal 60 is sealed in the accommodation space between the sealing frame 1, the heating element 20 and the U-shaped groove. During use, first bond one surface of the sealing frame 1 to the surface of the heating element 20, then buckle the shielding cover 40 upside down on the surface of the heating element 20, so that the bottom wall of the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com