Vertical Power Transistor Based on Arc Drain Plate and Schottky Drain

A power transistor, vertical technology, applied in the field of microelectronics, can solve the problems of inability to realize the reverse blocking function, failure of the current blocking layer, large drain-source leakage current, etc., and achieve easy implementation and continuous increase of reverse breakdown voltage , Improve the effect of reverse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

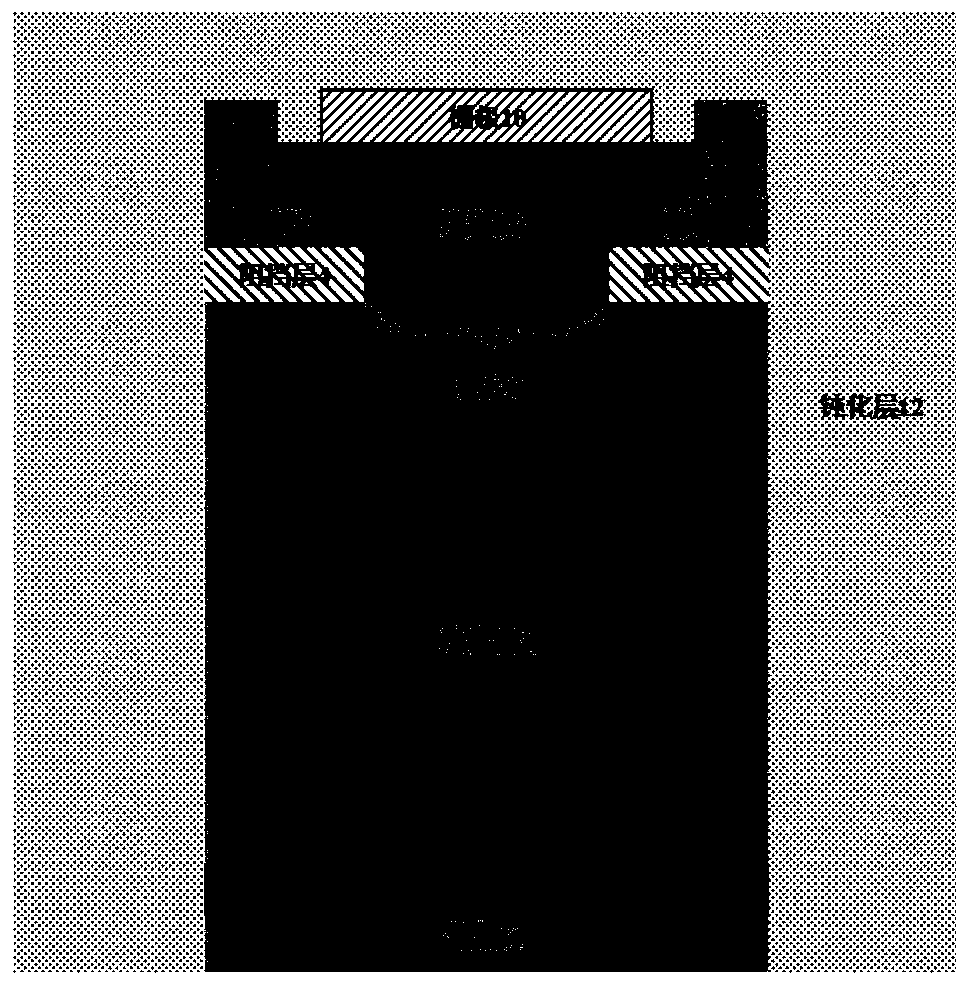

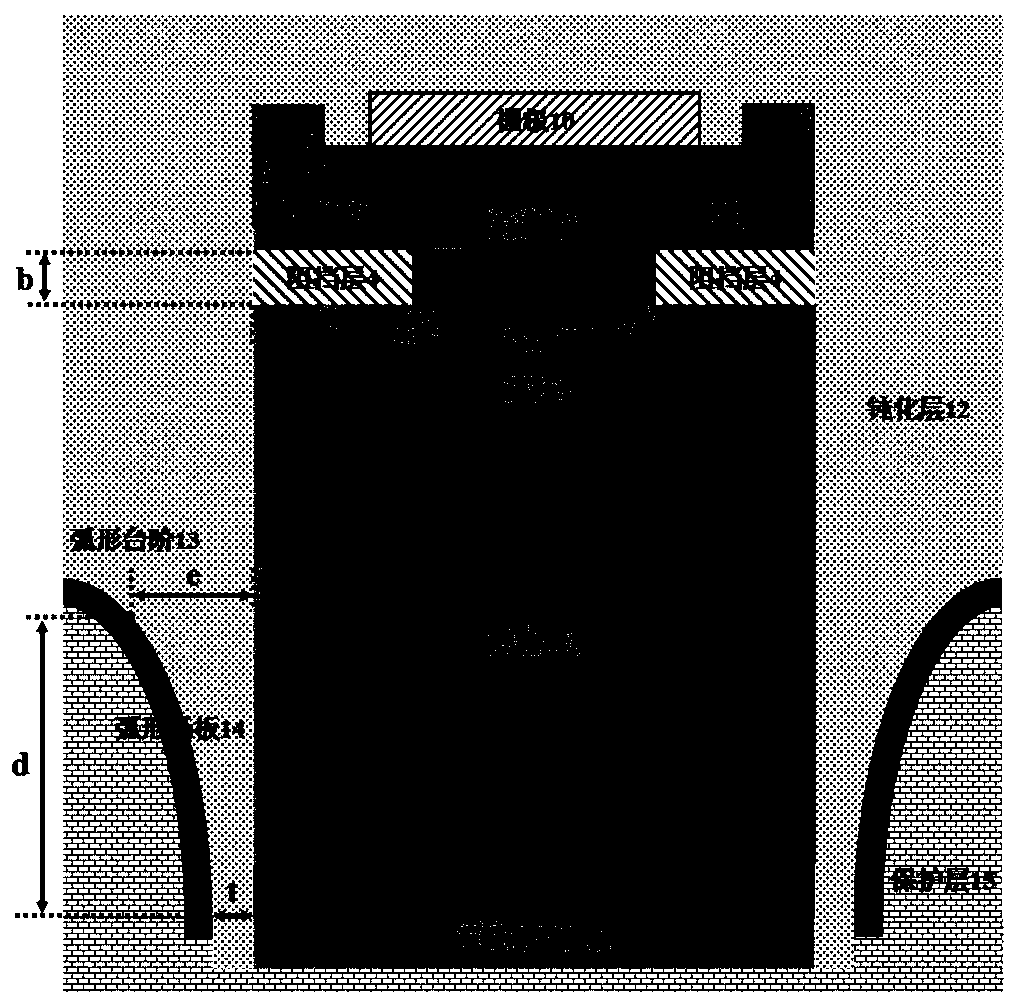

[0057] Embodiment 1: Fabricate a vertical power transistor based on a curved drain field plate and a Schottky drain in which both the passivation layer and the protective layer are SiN.

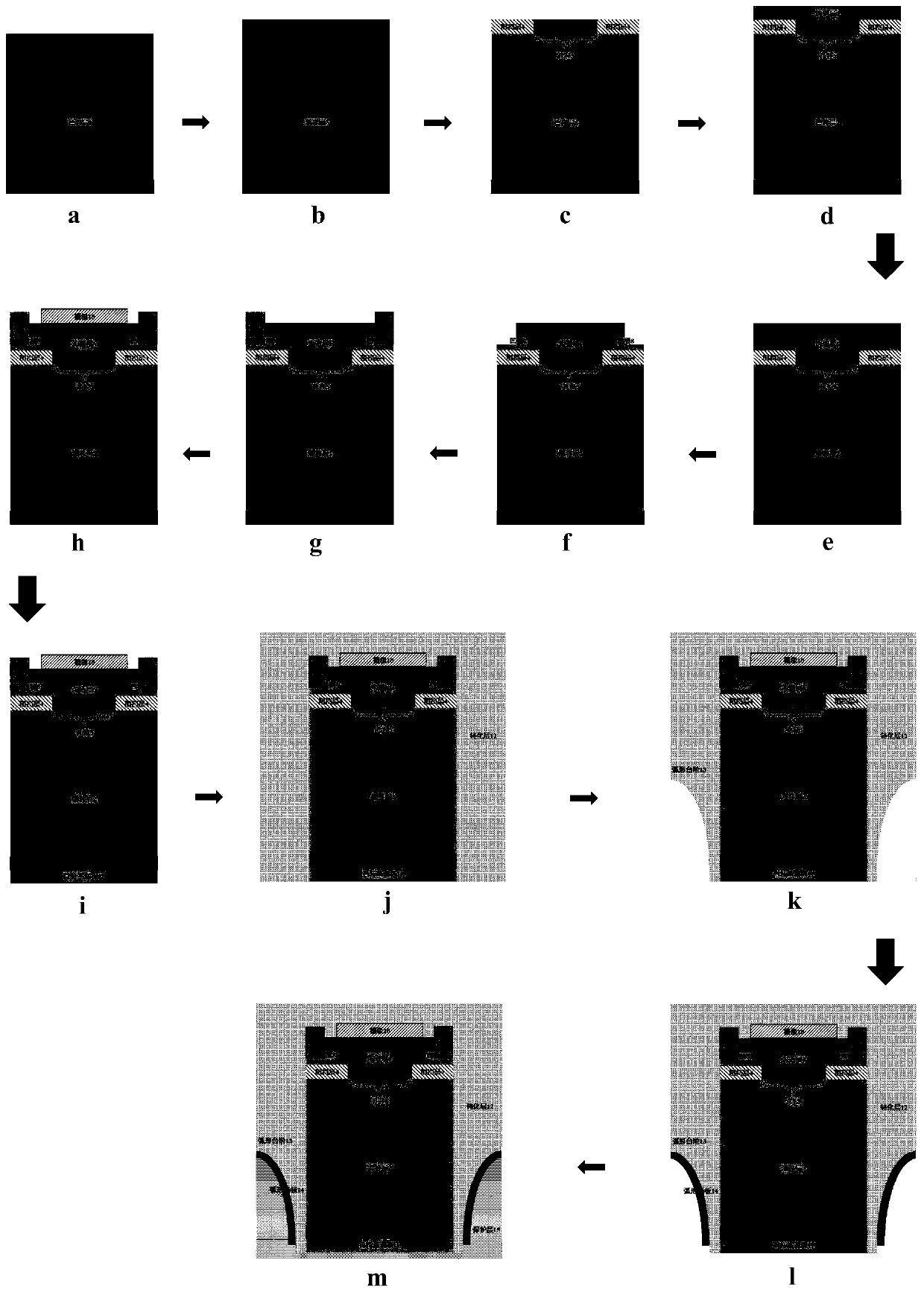

[0058] Step 1. Epitaxial n on the substrate - type GaN, forming a drift layer 2, such as image 3 a.

[0059] use n - type semiconductor material as the substrate 1, using the metal-organic chemical vapor deposition technique, the epitaxial thickness on the substrate 1 is 3 μm, and the doping concentration is 1×10 15 cm -3 the n - type GaN material to form a drift layer 2, wherein:

[0060] The process conditions used for epitaxy are: the temperature is 950°C, the pressure is 40Torr, and the SiH 4 As the doping source, the flow rate of hydrogen gas is 4000 sccm, the flow rate of ammonia gas is 4000 sccm, and the flow rate of gallium source is 100 μmol / min.

[0061] Step 2. Epitaxial n-type GaN on the drift layer to form an aperture layer 3, such as image 3 b.

[0062] Using metal-orga...

Embodiment 2

[0099] Embodiment 2: Both the passivation layer and the protective layer are made of SiO 2 Vertical power transistor based on curved drain field plate and Schottky drain.

[0100] Step 1. Epitaxial n on substrate 1 - type GaN, forming a drift layer 2, such as image 3 a.

[0101] At a temperature of 1000°C and a pressure of 45Torr, SiH 4 is the dopant source, the flow rate of hydrogen gas is 4400 sccm, the flow rate of ammonia gas is 4400 sccm, and the flow rate of gallium source is 110 μmol / min. - type semiconductor material as the substrate 1, using the metal-organic chemical vapor deposition technique, the epitaxial thickness on the substrate 1 is 25 μm, and the doping concentration is 1×10 16 cm -3 the n - type GaN material to complete the fabrication of the drift layer 2 .

[0102] The second step. Epitaxial n-type GaN on the drift layer to form the aperture layer 3, such as image 3 b.

[0103] At a temperature of 1000°C and a pressure of 45Torr, SiH 4 As the d...

Embodiment 3

[0132] Embodiment three: making passivation layer is SiO 2 , a vertical power transistor based on a curved drain field plate and a Schottky drain whose protective layer is SiN.

[0133] Step A. Take n - type semiconductor material as substrate 1, using metal-organic chemical vapor deposition technology, using a temperature of 950°C and a pressure of 40Torr, using SiH 4 As the doping source, the flow rate of hydrogen gas is 4000 sccm, the flow rate of ammonia gas is 4000 sccm, the flow rate of gallium source is 100 μmol / min, the epitaxial thickness on the substrate is 50 μm, and the doping concentration is 1×10 18 cm -3 the n - Type GaN material, making drift layer 2, such as image 3 a.

[0134] Step B. The temperature is 950°C, the pressure is 40Torr, and SiH 4 is the dopant source, the flow rate of hydrogen gas is 4000 sccm, the flow rate of ammonia gas is 4000 sccm, and the flow rate of gallium source is 100 μmol / min. Using metal organic chemical vapor deposition tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com