A conductive extracellular matrix composite film obtained through cell sheets and its preparation method

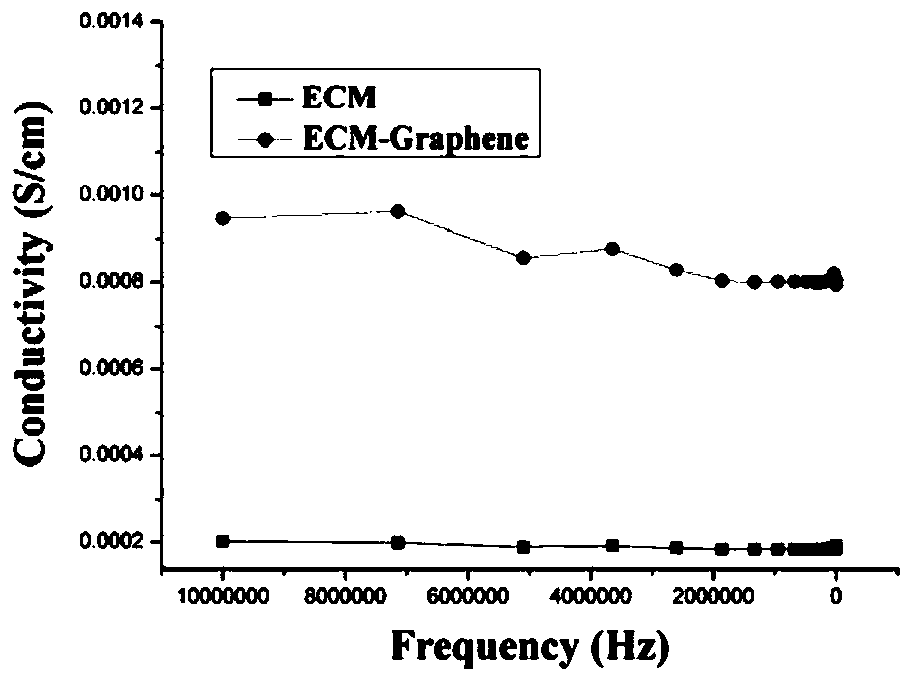

A technology of composite film and external matrix, applied in medical science, prosthesis, etc., can solve problems affecting functionality, etc., and achieve good electrical conductivity, easy implementation, good biocompatibility and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) For coated TiO 2 The surface of the nano-dot film is sterilized;

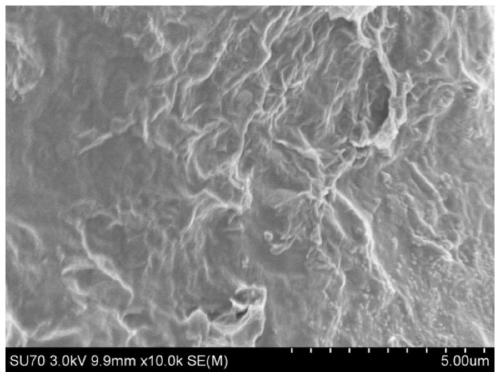

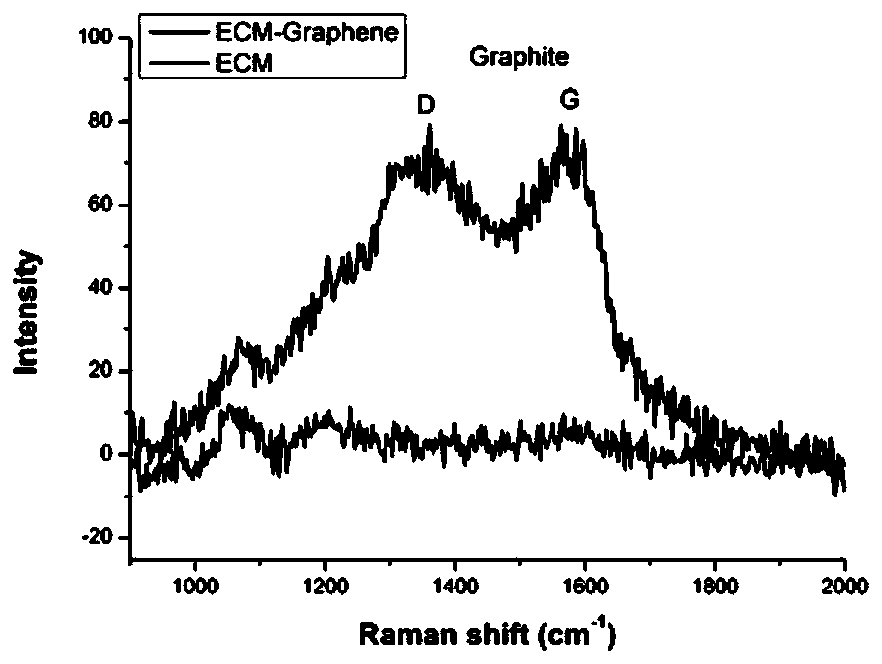

[0025] (2) Detach the cells previously cultured in the culture flask, centrifuge them at 800r / min for 6min, suspend them with α-MEM medium, and count them with a hemocytometer at 1×10 5 piece / cm 2 Cell density Seed the cells on the cell culture surface, place them in a carbon dioxide incubator for high-density culture for 10 days, change the medium for the first time after 2 days, then change the medium every 2 days, and add 100 μg of it one day before cell desorption / mL graphene nanosheets, eventually forming a complete cell sheet on the cell culture surface;

[0026] (3) By irradiating with ultraviolet light with a wavelength of 365nm for 30min, the cultured cell sheet containing conductive substances can be desorbed to obtain a complete cell sheet, and the desorbed cell sheet can be detached with PBS buffer and deionized water. The cell sheet was washed twice repeatedly.

[0027] (4) Soak the...

Embodiment 2

[0030] (1) For coated TiO 2 The surface of the nano-dot film is sterilized;

[0031] (2) Detach the cells previously cultured in the culture flask, centrifuge at 1300r / min for 2min, suspend with α-MEM medium, and count with a hemocytometer at 2×10 6 piece / cm 2 Cells were inoculated on the surface of the cell culture, and placed in a carbon dioxide incubator for high-density culture for 7 days. After 2 days, the medium was changed for the first time, and the medium was changed every 2 days thereafter. 1 μg was added 3 days before cell desorption. / mL graphene nanodots, eventually forming a complete cell sheet on the cell culture surface;

[0032] (3) By irradiating with ultraviolet light with a wavelength of 365nm for 5 minutes, the cultured cell sheet containing conductive substances can be desorbed to obtain a complete cell sheet, and the desorbed cell sheet can be detached with PBS buffer and deionized water. The cell sheet was washed 3 times repeatedly.

[0033] (4) Soa...

Embodiment 3

[0036] (1) For coated TiO 2 The surface of the nano-dot film is sterilized;

[0037] (2) Detach the cells previously cultured in the culture flask, centrifuge them at 1000r / min for 4min, suspend them with α-MEM medium, and count them with a hemocytometer at 5×10 4 piece / cm 2 Cells were inoculated on the surface of the cell culture, and placed in a carbon dioxide incubator for high-density culture for 15 days. After 2 days, the medium was changed for the first time, and the medium was changed every 3 days thereafter. 10 μg was added 2 days before cell desorption. / mL carbon nanofibers, and finally form a complete cell sheet on the cell culture surface;

[0038] (3) By irradiating with ultraviolet light with a wavelength of 365nm for 15 minutes, the cultured cell sheet containing conductive substances can be desorbed to obtain a complete cell sheet, and the desorbed cell sheet can be detached with PBS buffer and deionized water. The cell sheet was washed 3 times repeatedly. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com