Preparation method for cadmium sulfide-loaded hexagonal-phase ytterbium-and-erbium-doped sodium yttrium tetrafluoride composite photocatalyst

A technology of sodium tetrafluoroyttrium and cadmium sulfide, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as cumbersome operation and difficulty in controlling the morphology of upconversion nanoparticles, and achieve technological Simple, short reaction time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

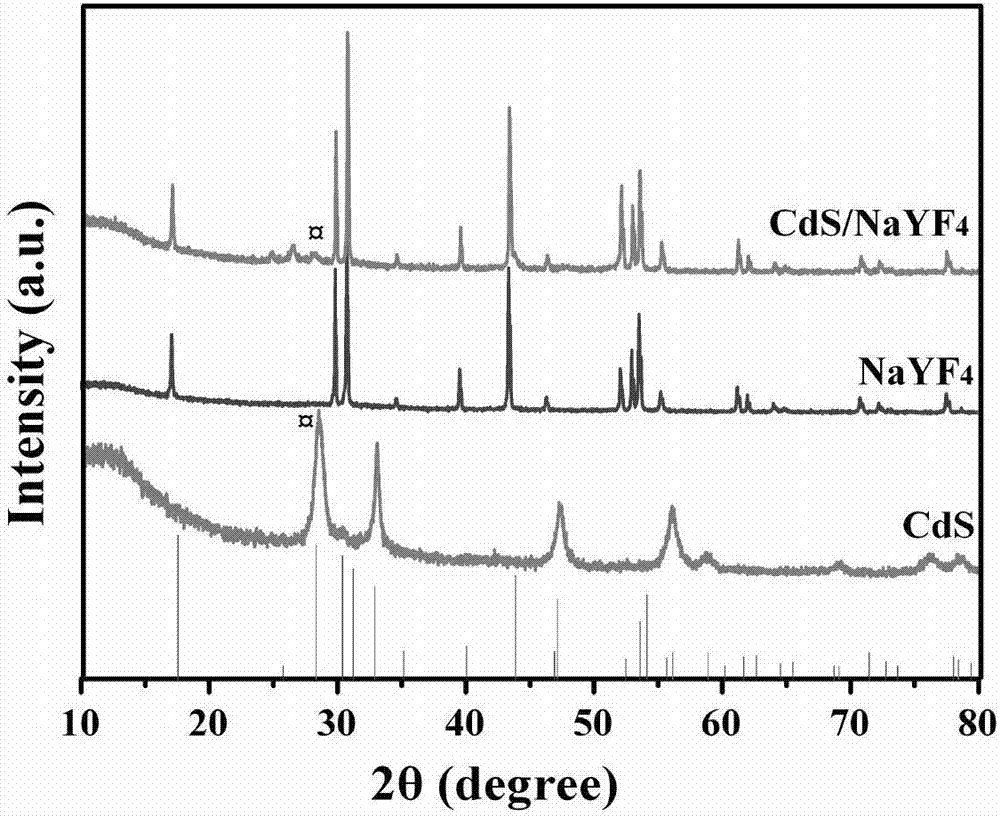

[0023] A preparation method of cadmium sulfide loaded hexagonal phase ytterbium and erbium-doped sodium tetrafluoroyttrium composite photocatalyst, comprising the steps of:

[0024] 1) Add 0.68mmolY (NO 3 ) 3 ·6H 2 O,0.2mmolYb(NO 3 ) 3 ·6H 2 O and 0.02mmolEr(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL deionized water and stirred for 30 min to obtain solution A;

[0025] 2) 2 mmol sodium citrate was dissolved in 15 mL deionized water to obtain solution B. Add solution B to A and stir for 30 minutes to finally obtain solution C;

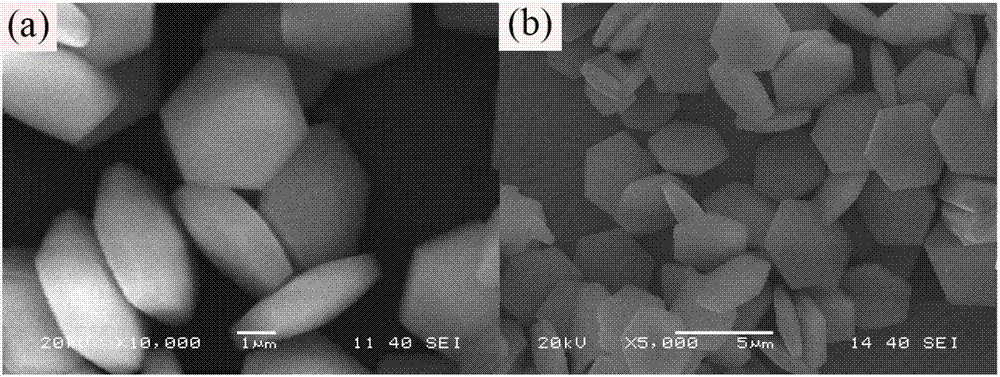

[0026] 3) Dissolve 12mmol NaF in 15mL deionized water to obtain solution D, add solution D to C and continue to stir for 30min, then add it to a 50mL reaction kettle and heat it at 180°C for 18h, wash the obtained sample three times with deionized water and ethanol, and heat Dry for 12h to get NaYF in hexagonal phase 4 :Yb, Er;

[0027] 4) 50 mg of the prepared hexagonal phase NaYF 4 : Dissolve Yb, Er samples in 10mL ethanol solution, add 1mL ...

Embodiment 1

[0030] 1) Add 0.68mmolY (NO 3 ) 3 ·6H 2 O,0.2mmolYb(NO 3 ) 3 ·6H 2 O and 0.02mmolEr(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL deionized water and stirred for 30 min to obtain solution A;

[0031] 2) 2 mmol sodium citrate was dissolved in 15 mL deionized water to obtain solution B. Add solution B to A and stir for 30 minutes to finally obtain solution C;

[0032] 3) Dissolve 12mmol NaF in 15mL deionized water to obtain solution D, add solution D to C and continue to stir for 30min, then add it to a 50mL reactor and heat at 180°C for 18h. The obtained sample was washed three times with deionized water and ethanol, and dried at 80°C for 12 hours to obtain the hexagonal NaYF 4 :Yb, Er;

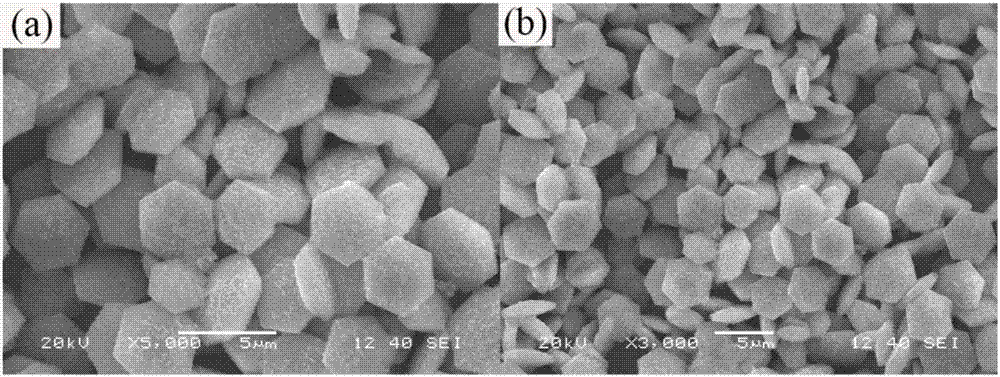

[0033] 4) 50 mg of the prepared hexagonal phase NaYF 4 : Dissolve Yb, Er samples in 10mL ethanol solution, add 1mL (0.2g / mL) PVP, ultrasonicate for 1h, add 10mg of pre-prepared CdS nanoparticles, stir for 1h, add to a 20mL reactor and heat at 160°C for 6h to obtain the final NaYF 4 : Yb...

Embodiment 2

[0036] 1) Add 0.68mmolY (NO 3 ) 3 ·6H 2 O,0.2mmolYb(NO 3 ) 3 ·6H 2 O and 0.02mmolEr(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL deionized water and stirred for 30 min to obtain solution A;

[0037] 2) 2 mmol sodium citrate was dissolved in 15 mL deionized water to obtain solution B. Add solution B to A and stir for 30 minutes to finally obtain solution C;

[0038] 3) Dissolve 12mmol NaF in 15mL deionized water to obtain solution D, add solution D to C and continue to stir for 30min, then add it to a 50mL reactor and heat at 180°C for 18h. The obtained sample was washed three times with deionized water and ethanol, and dried at 80°C for 12 hours to obtain the hexagonal NaYF 4 :Yb, Er;

[0039] 4) 50 mg of the prepared hexagonal phase NaYF 4 : Dissolve Yb and Er samples in 10mL ethanol solution, add 1mL (0.2g / mL) PVP, ultrasonicate for 1h, add 20mg of CdS nanoparticles prepared in advance, stir for 1h, add to 20mL reaction kettle and heat at 160℃ for 6h to obtain the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com