Linear polishing machining method and device based on magneto-rheological effect

A magneto-rheological effect and processing device technology, applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of difficulty in ensuring the integrity of the outer surface, the impact of processing quality, and the interface of tool marks. Achieve the effect of reducing workpiece scratches and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

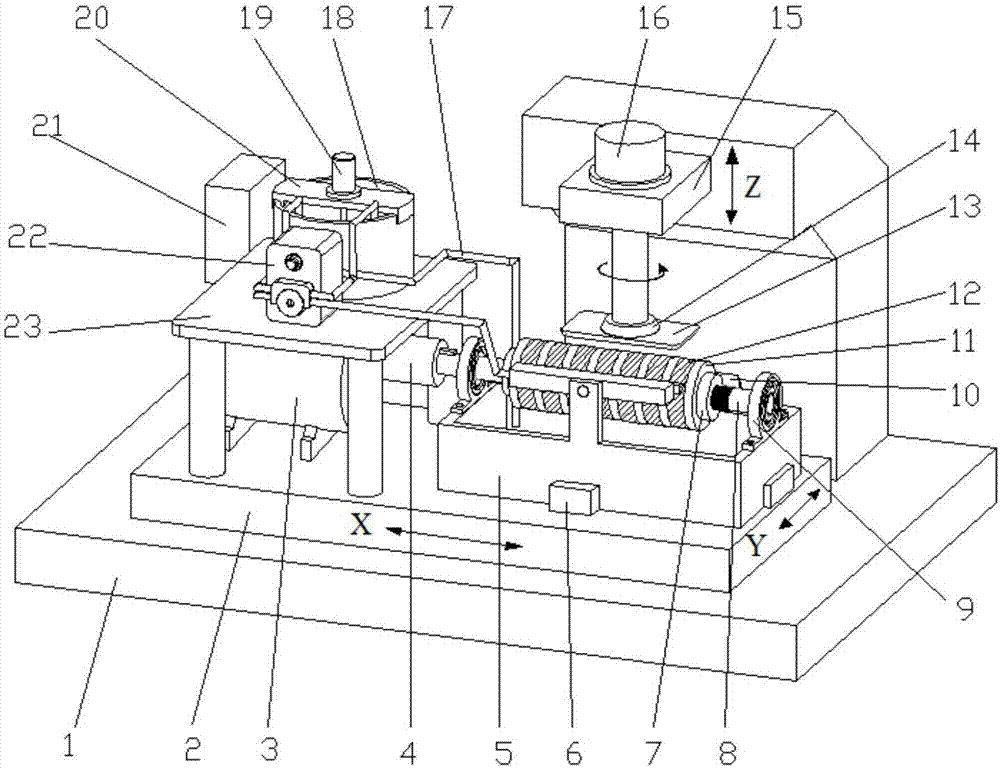

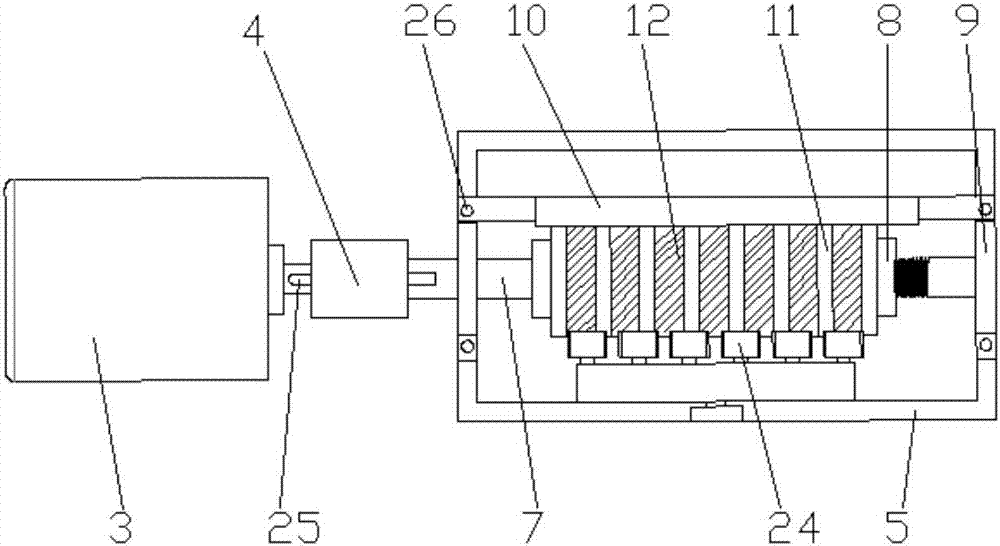

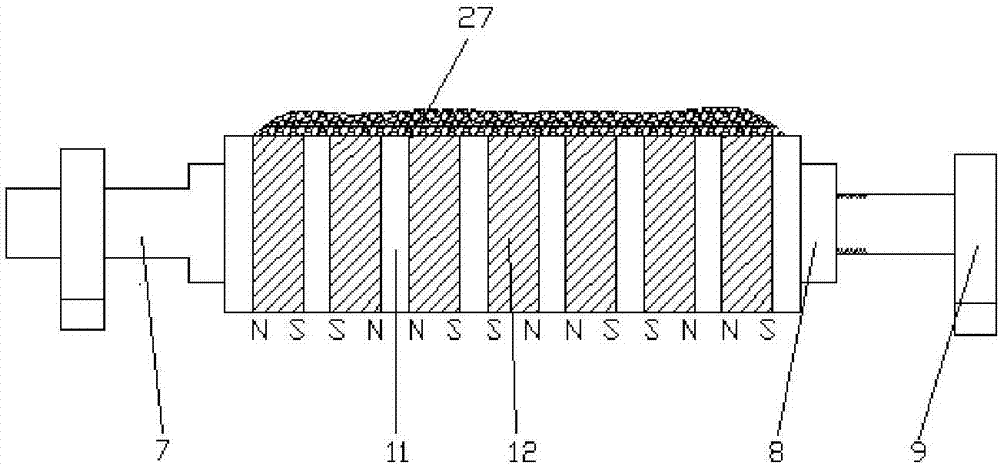

[0033] Such as figure 1 As shown, the present invention discloses a linear polishing processing device based on the magneto-rheological effect. Block 6, rotating shaft 7, rotating shaft nut 8, bearing pair 9, scraper 10, resin sheet 11, strong magnetic ring 12, mobile phone shell workpiece 13, vacuum sucker 14, vacuum pump installation block 15, vacuum pump 16, circulation pipe 17, working fluid container 18. Motor agitator 19, cover plate 20, control cabinet 21, multi-channel peristaltic pump 22, supporting platform 23, flat nozzle group 24.

[0034] The working fluid circulation unit includes a multi-channel peristaltic pump 22, a working fluid container 18, a motor agitator 19, a working fluid recovery tank 5, a circulation pipe 17, and a flat nozzle group 24; the polishing unit includes a speed regulating motor 3, a coupling 4, a rotating shaft 7. A resin sheet 11, a strong magnetic ring 12, a shaft nut 8; the workpiece clamping unit includes a workpiece 13, a vacuum chuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com