Short-cut nitrification and denitrification coupled anammox (anaerobic ammonium oxidation) and denitrification process and control method

A technology of anaerobic ammonium oxidation and short-cut nitrification, which is applied in the field of short-cut nitrification and denitrification coupling anammox denitrification process and control, which can solve the problems of inability to treat organic wastewater, low COD efficiency, and limited COD removal efficiency. , to achieve good promotion and application value, less control parameters, and overcome the effect of poor COD removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A short-cut nitrification and denitrification coupled anaerobic ammonium oxidation denitrification process and control method, comprising the following steps:

[0030] (1) The SBBR reactor filled with polyurethane (PU) sponge filler 5 is used, and the filling rate of the carrier filler is controlled at 50%~60%; among them, the filler is polymer synthetic hydrophilic polyurethane biofiller, with a side length of 2.5cm, And it is formed by double explosion of oxygen and hydrogen, with a hole diameter of 2~7mm, which penetrates each other.

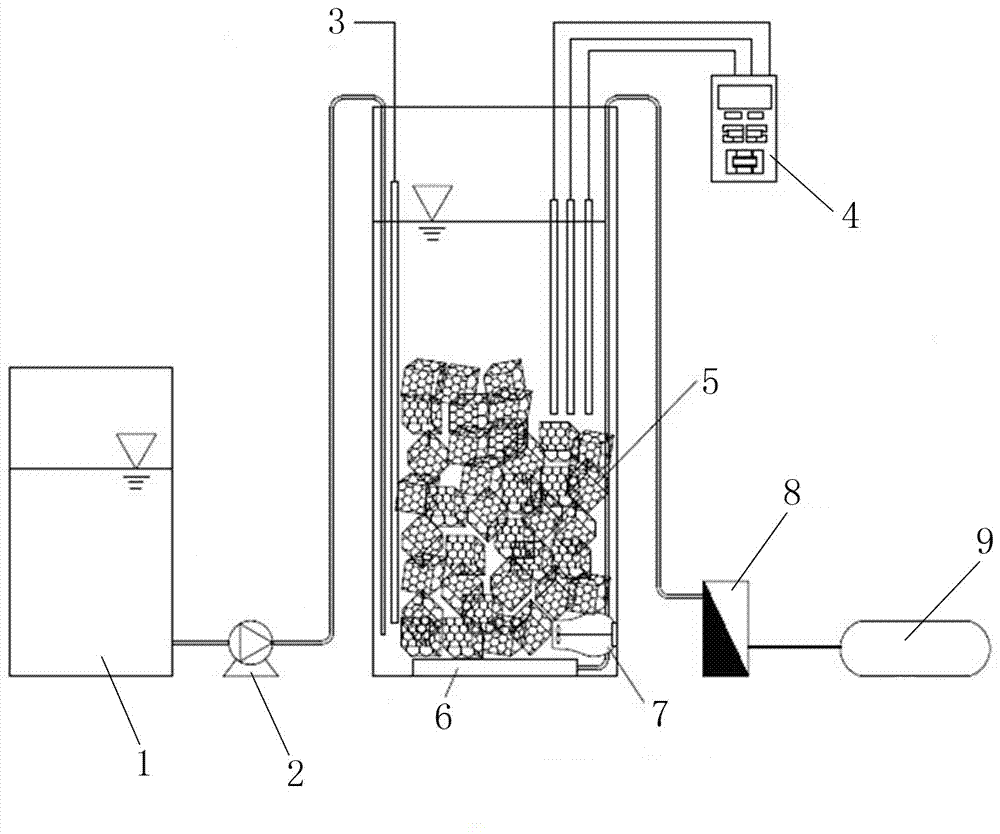

[0031] The structure of the SBBR reactor is as follows figure 1 As shown, the bottom is provided with a microporous aeration disc 6, and the aeration is provided by an air compression pump 9, which is connected to a gas rotameter 8 to adjust the air intake, and a mixing pump 7 is installed inside to ensure the full mixing of water, microorganisms and oxygen. Stir. A temperature control rod 3 and an online monitor 4 for pH, DO and ORP...

Embodiment 2

[0040] A short-cut nitrification and denitrification coupled anammox denitrification process and control method, the steps are the same as in Example 1, the difference is that the pretreated coal gasification wastewater B is treated in step (5), and the influent COD is about 700mg / L, Ammonia nitrogen: 320mg / L; in step (7), the removal rate of COD after treatment reaches 92%, the removal rate of ammonia nitrogen reaches 95%, and the removal rate of total nitrogen reaches 86%.

Embodiment 3

[0042] A short-range nitrification and denitrification coupled anammox denitrification process and control method, the steps are the same as in Example 1, the difference is that the pretreated slaughter wastewater C is treated in step (5), and the influent COD is about 1100mg / L. Ammonia nitrogen: 220mg / L; in step (7), the removal rate of COD after treatment reaches 95%, the removal rate of ammonia nitrogen reaches 93%, and the removal rate of total nitrogen reaches 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com