Unfired alumina-magnesite carbon brick and preparation method thereof

A technology of alumina-magnesia-carbon bricks and particle size, which is applied in the field of unfired alumina-magnesia-carbon bricks and its preparation, can solve the problems of insufficient shape and density of shaped bricks, mastering the details of the preparation process, and the impact of the greenhouse effect, etc., and achieve the improvement of workers' working conditions , superior performance, and the effect of improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

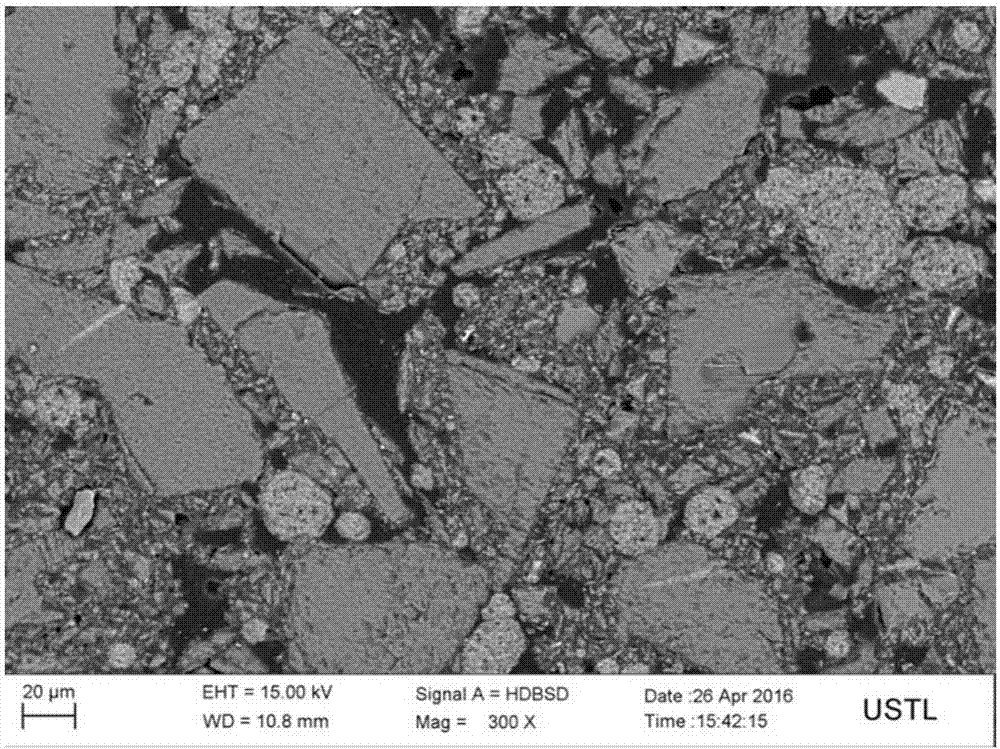

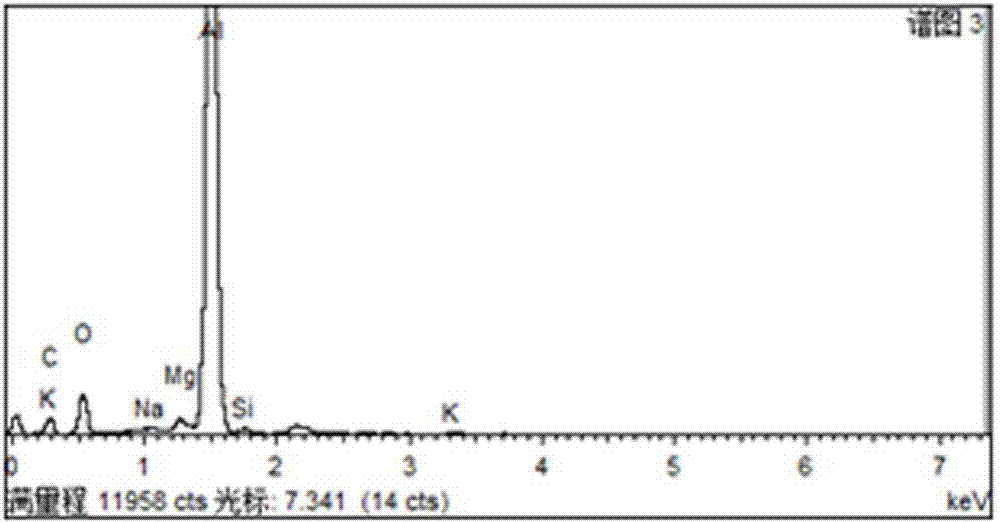

Image

Examples

Embodiment 1

[0037] The raw materials were weighed according to the components specified in Table 1 below, and the preparation method was as follows.

[0038] (1) Raw material processing

[0039] Aggregate: Weigh brown corundum and or super-grade bauxite according to parts by weight, put them into a jaw crusher for crushing, and crush them into large particles, then crush them with rollers, and then use a vibrating screen to screen out the aggregates with a particle size of 0.1-5mm. When changing materials for crushing and crushing, first clean up the accumulated materials in the silo and crushing equipment system.

[0040] Powder: Weigh high-purity fused magnesia, high-purity sintered magnesia, magnesia-aluminum spinel and sub-white corundum according to parts by weight and put them into the jaw crusher for crushing. After crushing into large particles, they are crushed by double rollers. Then vibrate and sieve to obtain particles with a particle size of 1-5mm, and then put them into a R...

Embodiment 2

[0053] The method of Example 1 was repeated at the contents of each component specified in Table 1 below, and the test results are listed in Table 3.

Embodiment 3

[0055] The method of Example 1 was repeated at the contents of each component specified in Table 1 below, and the test results are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com