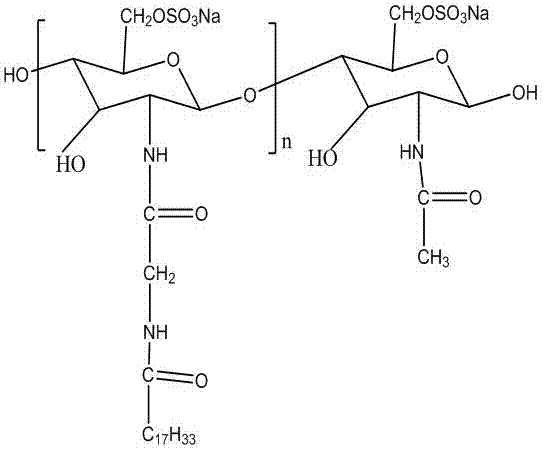

Sodium N-(N'-oleoylglycyl)-chitosan sulfonate and preparation method thereof

A technology of oleoyl glycyl and sodium sugar sulfonate is applied in chemical instruments and methods, pharmaceutical formulations, medical preparations of inactive ingredients, etc. Mild reaction conditions, mild properties, and the effect of saving reaction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] (1) Dissolve 0.2g (1.0mmol) oleic acid in anhydrous DMF first, add 0.12g (1.05mmol) NHS (N-hydroxysuccinimide) and 0.226g (1.1mmol) dicyclohexylcarbodiethylene Amine (DCC), stirred and reacted for 10-12 hours, and filtered after 10 hours of reaction to obtain filtrate (I).

[0033] Weigh 0.075g (1.0mmol) of glycine and 0.138g (1.0mmol) of potassium carbonate, add an appropriate amount of water to dissolve, slowly add the filtrate (I) dropwise in an ice-water bath, and after the dropwise addition, place it at room temperature for 24 hours to react to obtain N-acylglycine acid solution.

[0034] (2) Adjust the pH of N-oleoylglycyl solution to neutral with 3N hydrochloric acid, add 0.17g chitosan oligosaccharide (can be dissolved in a small amount of water in advance), 0.201g (1.05mmol) EDAC (1-(3-di Methylaminopropyl)-3-ethylcarbodiimide hydrochloride), reacted at room temperature for 24h to obtain a reaction solution containing N-(N'-oleoylglycyl)-chitooligosaccharide. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com