Intumescent halogen-free flame-retardant agent, halogen-free flame-retardant ethylene propylene diene monomer composition, halogen-free flame-retardant ethylene propylene diene monomer, and applications of halogen-free flame-retardant ethylene propylene diene monomer

A technology of EPDM rubber and flame retardant, applied in the field of flame retardant, can solve the problems of large amount of halogen-free flame retardant, insufficient flame retardant performance, and low elongation at break of rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-3

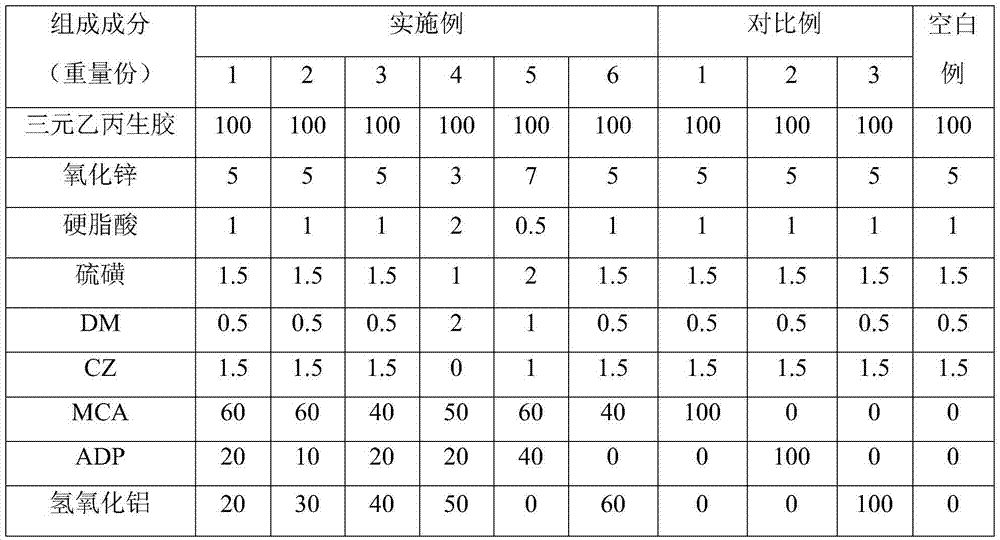

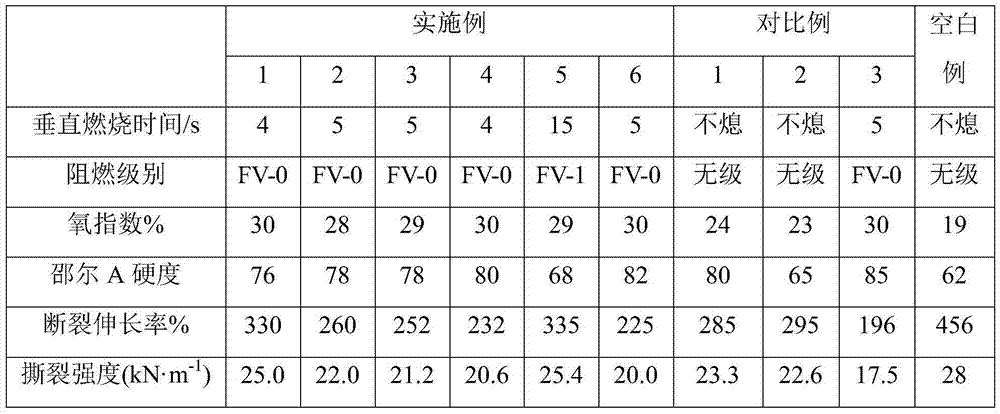

[0025] In Examples 1-6 and Comparative Examples 1-3, halogen-free flame retardant EPDM rubber products were prepared according to the following preparation methods and the dosage shown in Table 1, respectively, and a blank example without adding a flame retardant was additionally set. Wherein the preparation method is:

[0026]Take 100 parts by weight of raw EPDM rubber (brand P750NR, Mitsui Chemicals, Japan, whose third monomer is ENB), thinly pass 4 times on an open mill, and after wrapping rolls, adjust the roll distance to 1 mm, and sequentially Add stearic acid, zinc oxide, melamine cyanurate (MCA), aluminum diethylphosphinate (ADP) and aluminum hydroxide, mix for 12min, add sulfur and vulcanization accelerator (including DM, CZ, industrial grade , Guangzhou Donghong Chemical Factory), knead evenly, beat the triangle bag 5 times, roll 3 times, and then unload the film, and vulcanize it with a flat vulcanizer at 160 ° C × 10 min to obtain a halogen-free flame retardant EP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com