Polyurethane elastomer and preparation method and application thereof

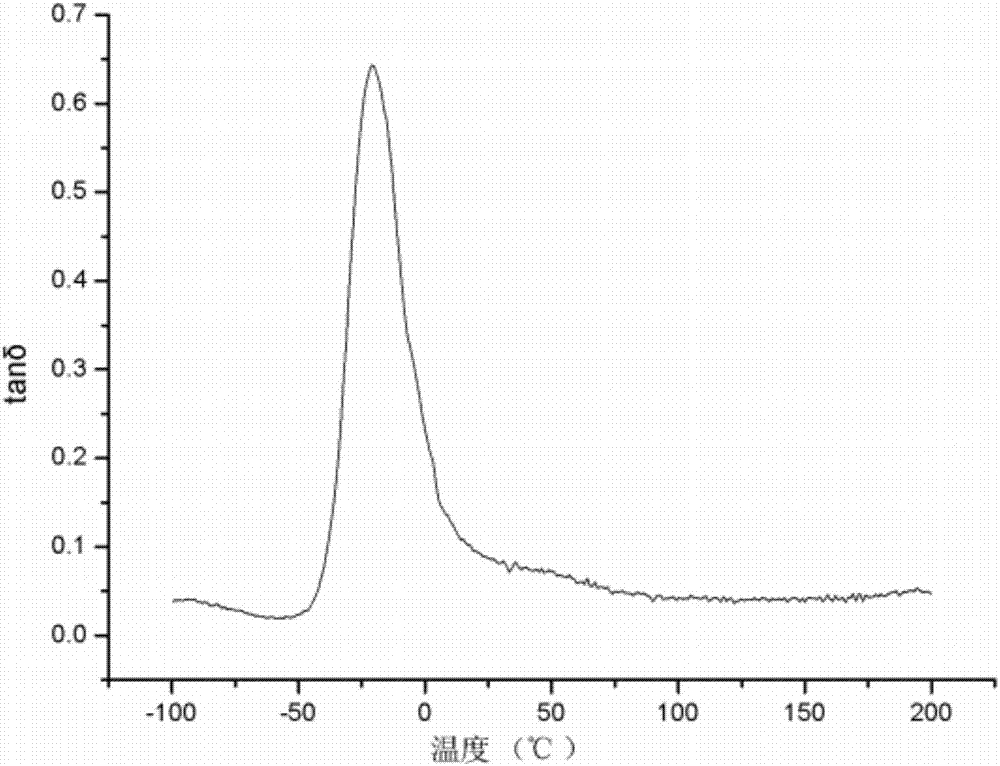

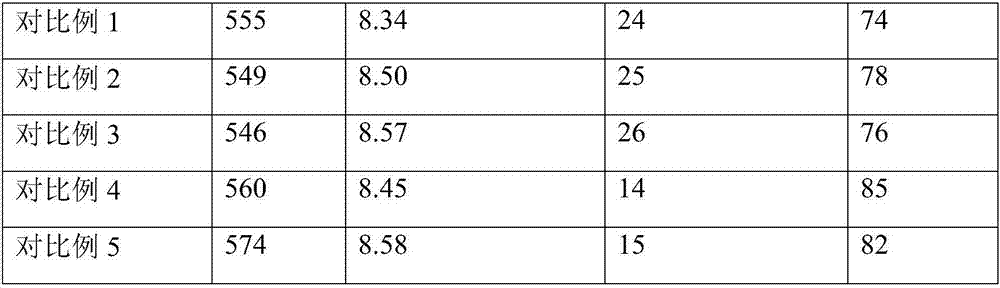

A polyurethane elastomer and prepolymer technology, applied in the field of polymer materials, can solve the problems of unsuitable application requirements and high hardness, and achieve the effects of excellent elongation at break, good unidirectional elongation, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of polyurethane elastomer of the present invention specifically comprises the steps:

[0020] S101: First, mix 30-50 parts by weight of naphthalene diisocyanate and 100-150 parts by weight of polyether polyol, then heat to 110-130°C and stir for 5h-8h to obtain the a prepolymer;

[0021] S102: 1-10 parts by weight of isophorone diisocyanate, 0.1-1 part by weight of diphenylmethane diisocyanate, and 0.1-1 part by weight of toluene diisocyanate Mix with 10 to 20 parts by weight of polyester polyol, then heat to 100°C to 110°C and stir for 4h to 6h to obtain the second prepolymer;

[0022] S103: Add 0.1-1 part by weight of a chain extender and 10-20 parts by weight of isophorone diisocyanate to the first prepolymer, and then stir and react for 3h-6h, Obtain the third prepolymer;

[0023] S104: Add 0.1-1 part by weight of chain extender and 10-20 parts by weight of naphthalene diisocyanate to the second prepolymer, and then stir and react for 3h-6h...

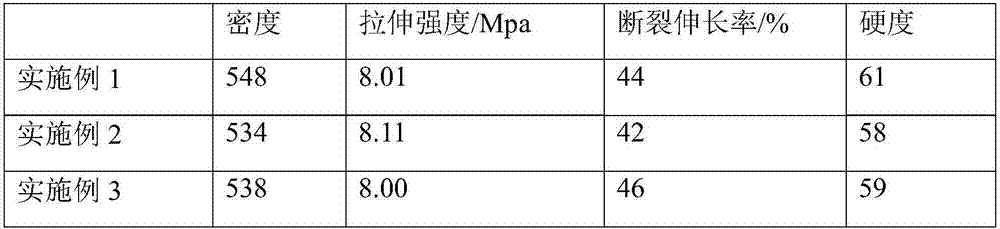

Embodiment 1

[0030] Embodiment 1 proposes a kind of preparation method of polyurethane elastomer, specifically comprises the following steps:

[0031] (1) First, 30 parts by weight of naphthalene diisocyanate and 150 parts by weight of polyoxypropylene diol were mixed, then heated to 110° C. and stirred for 8 hours to obtain the first prepolymer.

[0032] (2) parts by weight are 1 part of isophorone diisocyanate, 1 part of diphenylmethane diisocyanate, 0.1 part of toluene diisocyanate and 20 parts of Polyadipate-butylene glycol was mixed, then heated to 100°C and stirred for 6h to obtain the second prepolymer.

[0033] (3) Add 0.1 parts by weight of propylene glycol and 20 parts by weight of isophorone diisocyanate to the first prepolymer, and then stir and react for 3 hours to obtain a third prepolymer.

[0034] (4) Add 1 part by weight of 4,4'-bis-sec-butylaminodiphenylmethane and 10 parts by weight of naphthalene diisocyanate to the second prepolymer, and then stir and react for 6 hour...

Embodiment 2

[0040] Embodiment 2 proposes a kind of preparation method of polyurethane elastomer, specifically comprises the steps:

[0041] (1) First, 50 parts by weight of naphthalene diisocyanate and 100 parts by weight of polytetrahydrofuran diol were mixed, then heated to 130°C and stirred for 5 hours to obtain the first prepolymer.

[0042] (2) parts by weight are 10 parts of isophorone diisocyanate, 0.1 parts of diphenylmethane diisocyanate, 1 part of toluene diisocyanate and 10 parts of The polycaprolactone was mixed, then heated to 110° C. and stirred for 4 hours to obtain the second prepolymer.

[0043] (3) Add 1 part by weight of 1,4-bis-sec-butylaminobenzene and 10 parts by weight of isophorone diisocyanate to the first prepolymer, then stir and react for 6 hours to obtain third prepolymer.

[0044] (4) Add 0.1 parts by weight of ethylene glycol and 20 parts by weight of naphthalene diisocyanate to the second prepolymer, and then stir and react for 3 hours to obtain a fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com