Preparation method of super-hydrophobic polyethylene fiber film

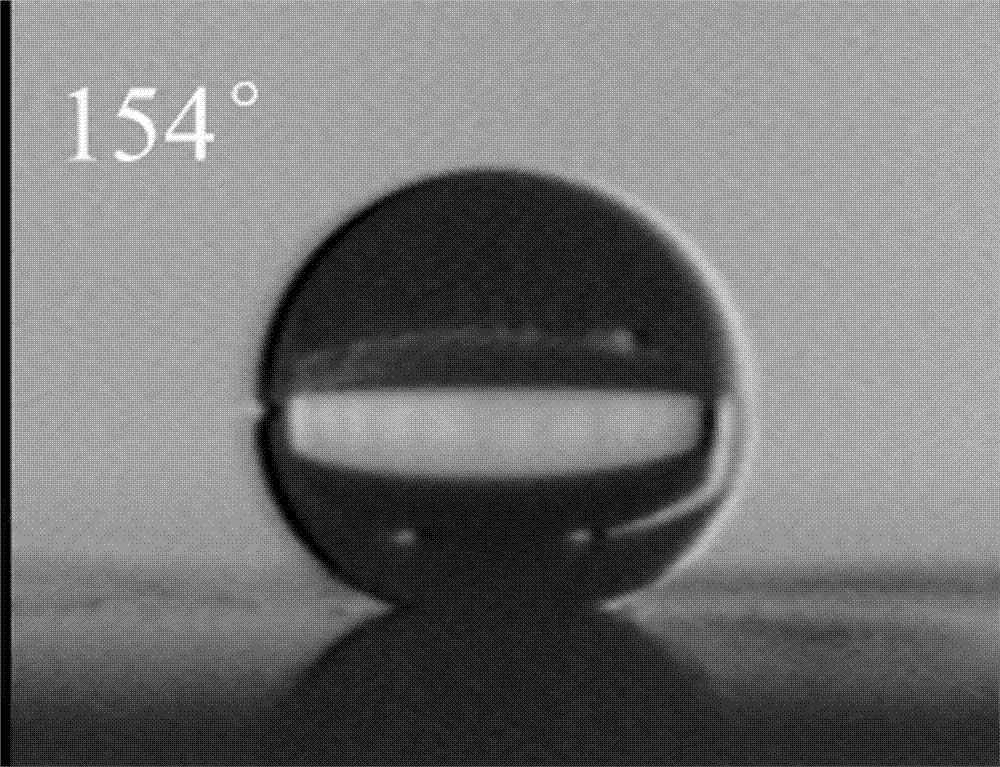

A polyethylene fiber and super-hydrophobic technology, applied in spinning solution preparation, textiles and papermaking, non-woven fabrics, etc., can solve the problems of long cycle, high cost, unsuitable for industrial promotion and application, etc., and achieve short cycle and easy operation Convenience and the effect of increasing the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

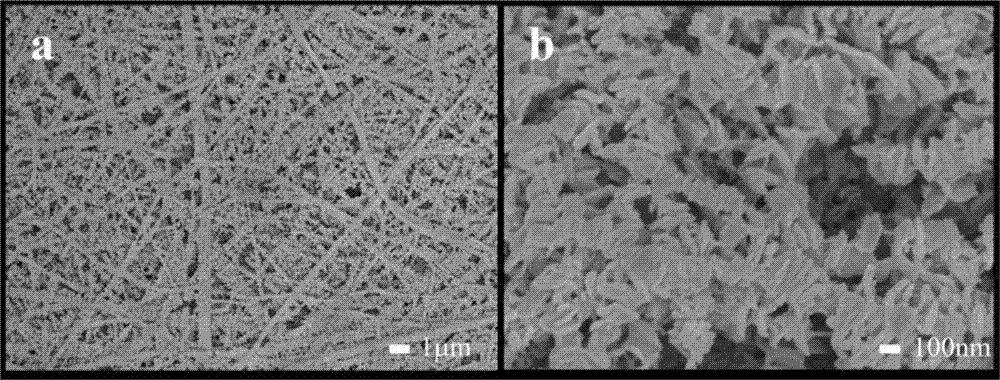

[0029] The preparation method of the superhydrophobic polyethylene fiber film of this embodiment, the specific operation steps are:

[0030] 1) Preparation of ultra-high molecular weight polyethylene spinning solution: take ultra-high molecular weight polyethylene powder and add it to the organic solvent xylene, and dissolve it at 140°C for more than 10 minutes until the ultra-high molecular weight polyethylene powder is completely dissolved in xylene to obtain Mass concentration is 0.05% ultra-high molecular weight polyethylene solution;

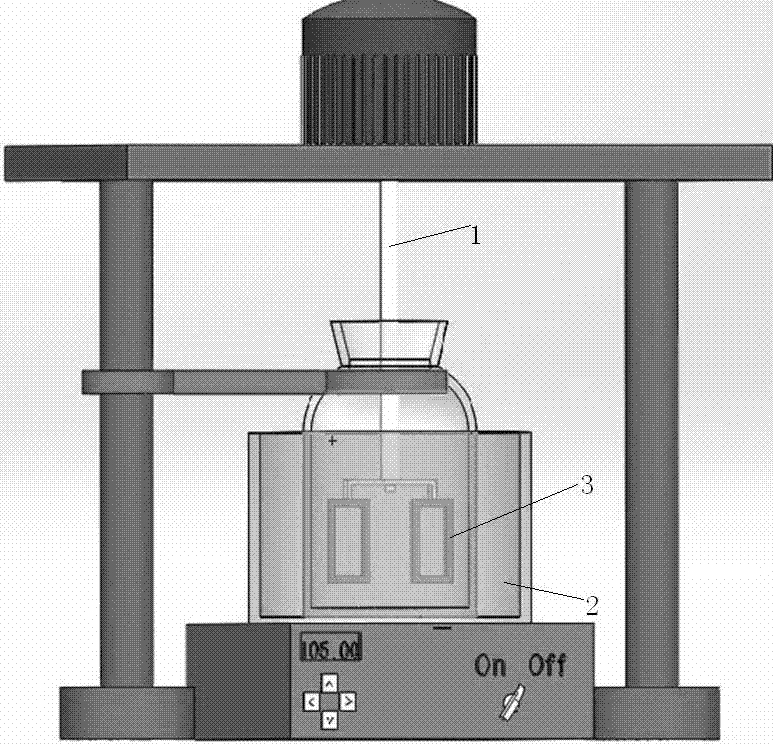

[0031] 2) Spinning and film spinning: such as figure 1 As shown, a stirring rod is set above the oil bath, and two steel wire frames are fixed and fixed symmetrically under the stirring rod, and the ultra-high molecular weight polyethylene solution prepared in step 1) is transferred to the inner diameter of the cylinder placed in the oil bath. In a 35mm necked glass container, the volume of the ultra-high molecular weight polyethylene solu...

Embodiment 2

[0039] The preparation method of the superhydrophobic polyethylene fiber film of this embodiment, the specific operation steps are:

[0040] 1) Preparation of ultra-high molecular weight polyethylene spinning solution: take ultra-high molecular weight polyethylene powder and add it to the organic solvent xylene, and dissolve it at 140°C for more than 10 minutes until the ultra-high molecular weight polyethylene powder is completely dissolved in xylene to obtain A mass concentration of 0.01% ultra-high molecular weight polyethylene solution;

[0041] 2) Spinning and film spinning: set a stirring bar above the oil bath, and connect two steel wire frames symmetrically and symmetrically below the stirring bar, transfer the ultra-high molecular weight polyethylene solution prepared in step 1) to the oil bath, The wire frame is immersed in the ultra-high molecular weight polyethylene solution, the oil bath temperature is set to 110°C, the stirring rate is set to 800r / min, and the co...

Embodiment 3

[0045] The preparation method of the superhydrophobic polyethylene fiber film of this embodiment, the specific operation steps are:

[0046] 1) Preparation of ultra-high molecular weight polyethylene spinning solution: take ultra-high molecular weight polyethylene powder and add it to the organic solvent xylene, and dissolve it at 140°C for more than 10 minutes until the ultra-high molecular weight polyethylene powder is completely dissolved in xylene to obtain Mass concentration is 0.5% ultra-high molecular weight polyethylene solution;

[0047] 2) Spinning and film spinning: set a stirring bar above the oil bath, and connect two steel wire frames symmetrically and symmetrically below the stirring bar, transfer the ultra-high molecular weight polyethylene solution prepared in step 1) to the oil bath, The steel wire frame is immersed in the ultra-high molecular weight polyethylene solution, the oil bath temperature is set at 115°C, the stirring rate is set at 800r / min, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com