A kind of drainage device and drainage device prefabricated

A drainage device and drainage ditch technology, which is applied in drainage, safety devices, mining equipment, etc., can solve problems such as poor drainage, water overflow, and inability to solve mine drainage ditch mud cleaning well, so as to quickly clean up mud and liberate Labor force, the effect of reducing human and material resource expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

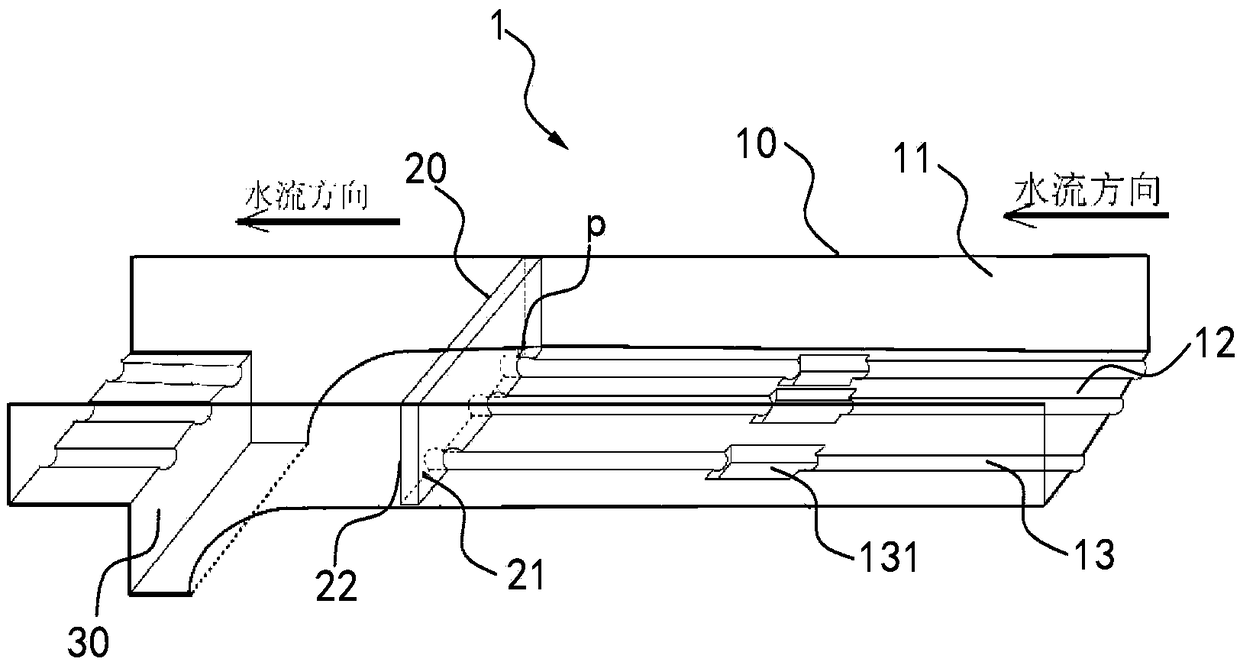

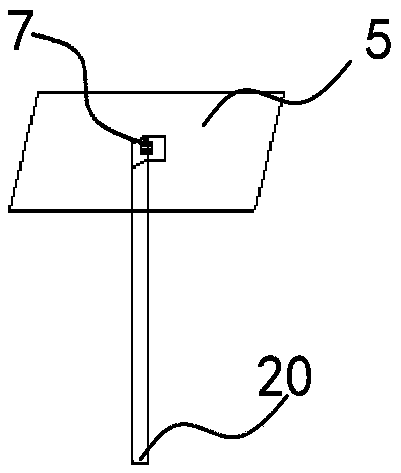

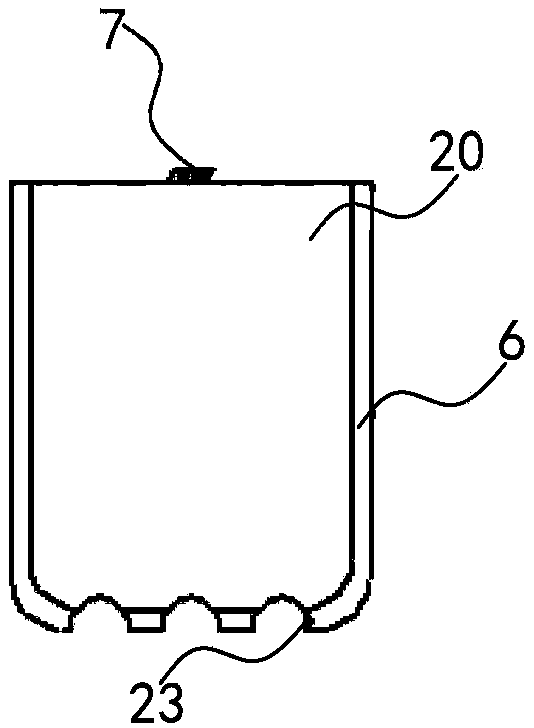

[0046] combine figure 1 Let's look at Example One. In the drainage device 1 shown in Embodiment 1, the arrows indicate the direction of water flow, and upstream and downstream are defined according to the direction of water flow. The drainage device 1 comprises a drainage ditch 10 and at least one baffle 20 arranged in the drainage ditch, and the baffle 20 defines an upstream side 21 and a downstream side 22 according to the direction of water flow. The drainage ditch 10 includes two sidewalls 11 and a bottom surface 12, wherein the connection between the bottom surface 12 and the two sidewalls 11 is set as a circular arc transition surface. Wherein, three lower notches 23 are provided on the lower end side of the baffle plate 20, and these three lower notches 23 are set as semicircles in this embodiment. The bottom surface 12 of the drainage ditch is provided with three water guide grooves 13 along the length direction of the water drainage ditch 10. The water guide grooves...

Embodiment 2

[0058] Such as Figure 8 shown. In the second embodiment, on the basis of the first embodiment, a silt storage frame 8 is placed in each sedimentation pit 30 . The mud storage frame 8 has several drainage holes 81 for collecting slag. When the slag is deposited to a certain thickness, the silt storage frame 8 is proposed, and the drain hole 81 can remove water, reduce the weight of slag in the silt storage frame 8, and save manpower, which is more convenient and efficient than the first embodiment. The sludge storage frame 8 also has a handle 82 . Silt storage frame 8 can adopt durable plastic material, can resist corrosion and reduce self weight.

Embodiment 3

[0059] Embodiment three such as Figure 9 Shown is the structural representation of embodiment three. In the third embodiment, two or more components of the drainage device 1 in the first embodiment are manufactured together to form a prefabricated module 9 . The groove body of the prefabricated module 9 can be made of metal, plastic or composite material. In this embodiment, fiber-reinforced composite material is used as an example, and integral molding can be selected to form the bottom surface structure at one time. In a specific example, the bottom surface 12 and the side wall 11 of the prefabricated module 9 can be formed of glass fiber reinforced plastics, which can take full advantage of its advantages of low cost and high strength, and is easy to mass produce.

[0060] When in use, the prefabricated module 9 can be directly placed in the original mine tunnel. The bottom surface 12 and the two side walls 11 of the drainage device 1 of each monomer of the prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com