Method for drying pumpkins

A drying method and technology of pumpkin, applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of large nutrient loss, high energy consumption, speed up drying rate, etc. The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

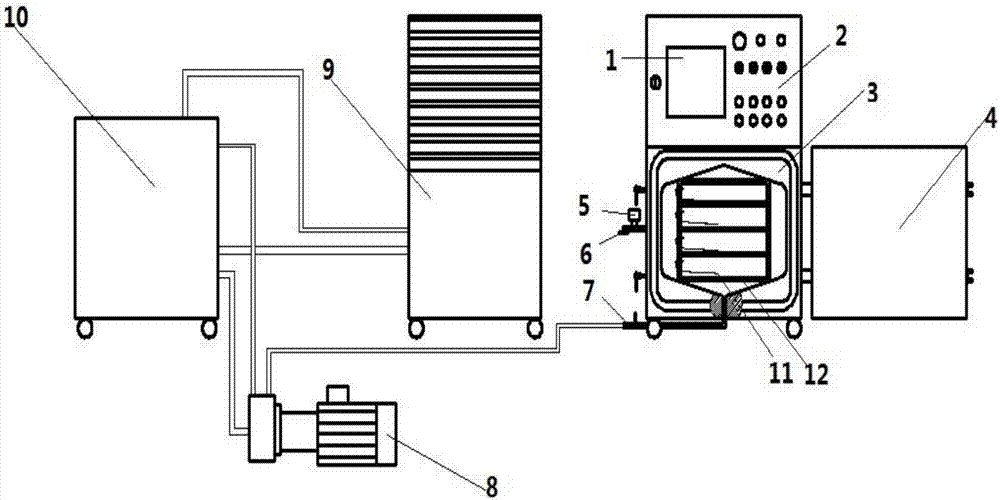

Method used

Image

Examples

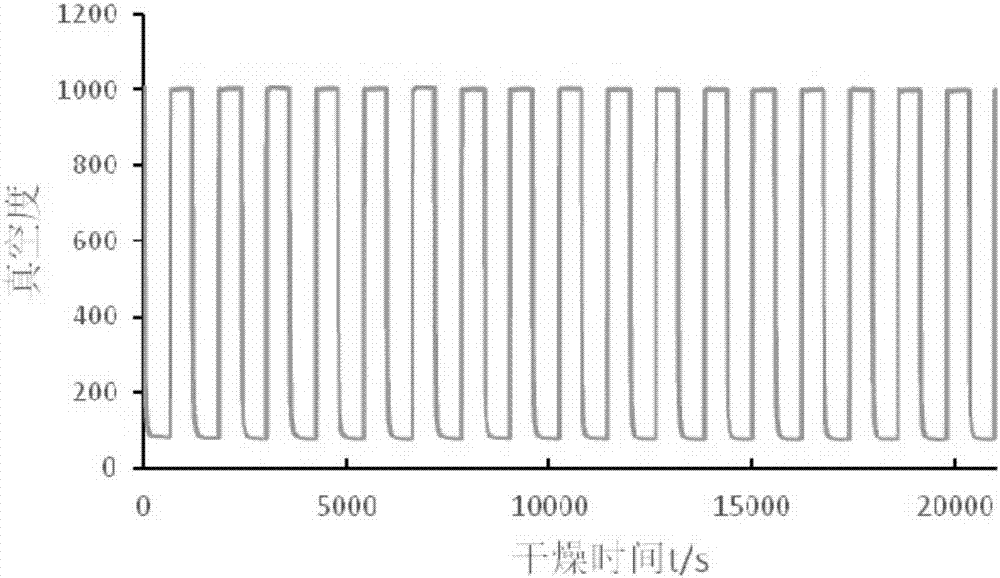

Embodiment 1

[0033] Cut the pumpkin in half according to the roundness direction, put it on the slicer for thickness slicing, adjust the knife edge of the slicer until the thickness of the sliced pumpkin is 5mm, cut off the seeds and flocs, and place them evenly on a weighed iron tray. Take another tray and put two pumpkin slices into the temperature sensor to monitor the temperature change of the pumpkin slices. Before drying, set the drying temperature to 50°C, alternate vacuum for 10 minutes and normal pressure for 9 minutes, and take it out after 3 hours. The measured moisture content is 8%, and the rehydration rate is 5.26. The L*, a*, and b* values of the material are measured with a colorimeter, and the L*, a*, and b* values are obtained through OpenRGB software analysis. * 、C * , H ° mean values were 63.80, 67.78 and 64.60. The results showed that when the pumpkin slices were thin, the dry basis with good rehydration rate and little color change could be obtained by adjus...

Embodiment 2

[0035]Cut the pumpkin in half according to the roundness direction, put it on the slicer for thickness slicing, adjust the knife edge of the slicer until the thickness of the obtained pumpkin slices is 7mm, remove the seeds and flocs, and place them evenly on a weighed iron tray. Take another tray and put two pumpkin slices into the temperature sensor to monitor the temperature change of the pumpkin slices. Before drying, set the drying temperature to 60°C, alternate vacuum for 10 minutes and normal pressure for 9 minutes, and take it out after 6 hours. The measured moisture content is 5%, and the rehydration rate is 4.37. The L*, a*, and b* values of the material are measured with a colorimeter, and the L*, a*, and b* values are obtained through OpenRGB software analysis. * 、C * , H ° mean values were 66.24, 62.93 and 64.13. The results show that the dry basis rehydration rate and color change obtained under this condition are ideal.

Embodiment 3

[0037] Cut the pumpkin in half according to the roundness direction, put it on the slicer for thickness slicing, adjust the knife edge of the slicer until the thickness of the obtained pumpkin slices is 7mm, remove the seeds and flocs, and place them evenly on a weighed iron tray. Take another tray and put two pumpkin slices into the temperature sensor to monitor the temperature change of the pumpkin slices. Before drying, set the drying temperature to 60°C, alternate between vacuum for 10 minutes and normal pressure for 5 minutes, and take out and weigh after 6 hours. The measured moisture content is 5%, and the rehydration rate is 3.29. The L*, a*, and b* values of the material are measured with a colorimeter, and the L*, a*, and b* values are obtained through OpenRGB software analysis. * 、C * The average values of , H° were 57.13, 64.92 and 61.98, respectively, indicating that shortening the normal pressure time had little effect on the color of the dry base, but the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com