Ag/g-C3N4 composite photocatalyst and preparation method thereof

A composite light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low crystallinity, high exciton binding energy, photogenerated carrier mobility minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

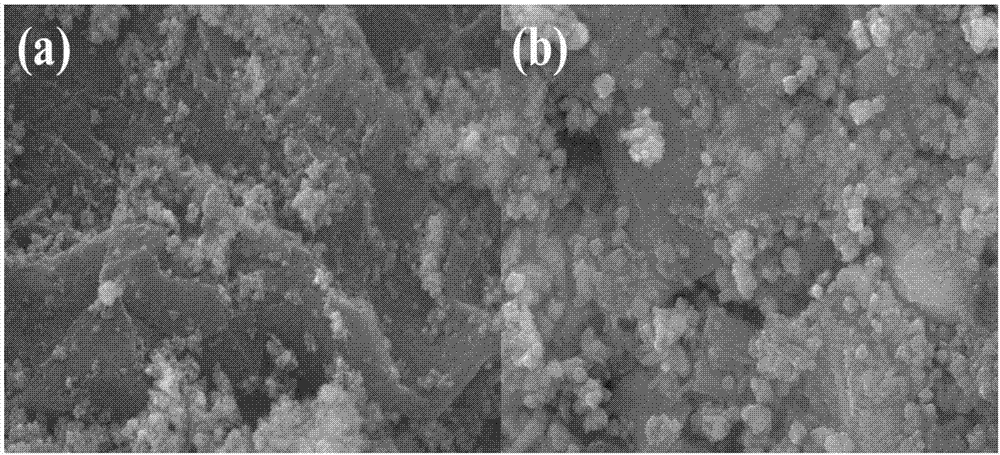

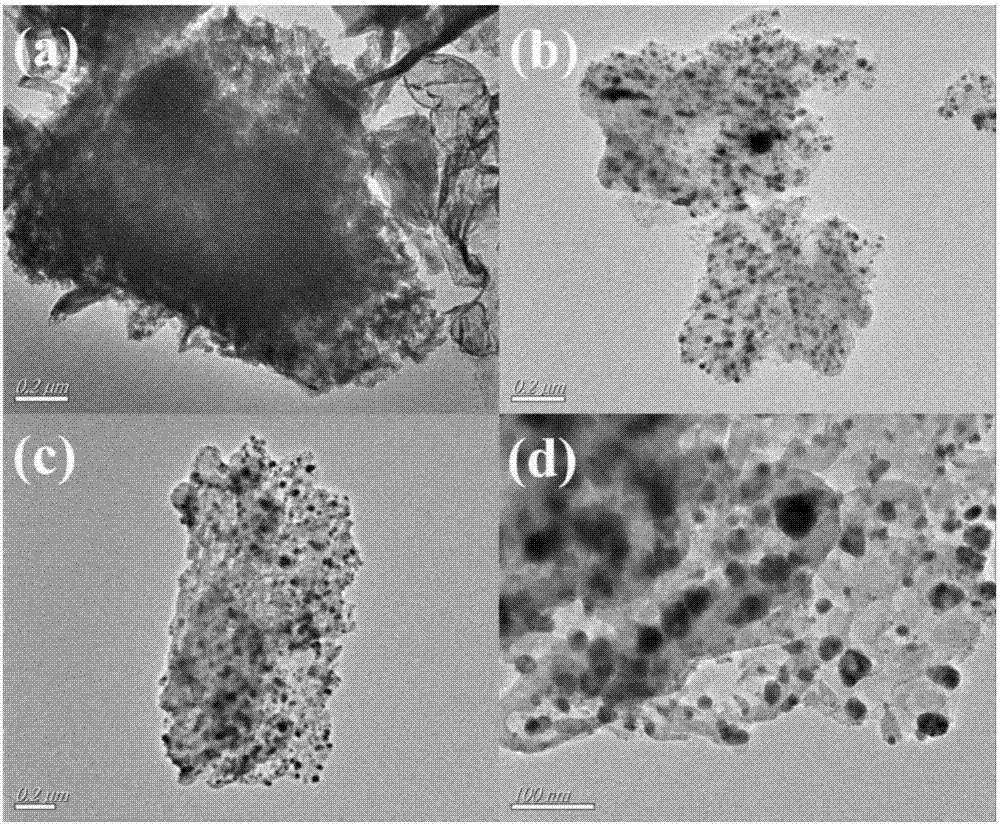

[0027] (1) g-C 3 N 4 Preparation of nanosheets:

[0028] 3 g of melamine was calcined, moved to a 600°C muffle furnace for calcination for 3 hours, and the heating rate was 4.5°C / min. After the calcination is finished, take out and grind; then the powder is calcined in the same procedure to obtain g-C 3 N 4 Nanosheets. Then add 1 g of g-C 3 N 4 The nanosheets are placed in a 60cm 3 Deionized water and 0.30g NaOH were mechanically stirred in a beaker for 30min; then, the solution was transferred to a 110°C reactor for 18h constant temperature thermal reaction; after the reaction was completed, the solid product was washed with deionized water and ethanol, Dried to give g-C 3 N 4 Nanosheets.

[0029] (2) Ag / g-C 3 N 4 Preparation of:

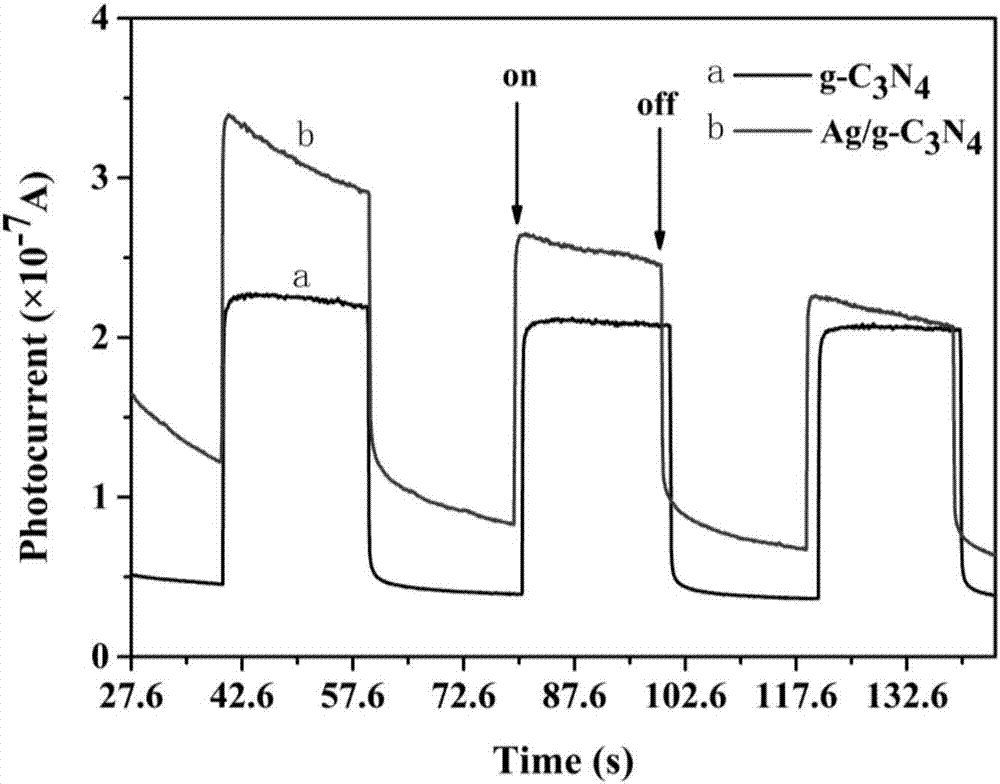

[0030] 0.20g of g-C 3 N 4 nanosheets and 0.05g AgNO 3 Dissolve in 50ml deionized water and stir; then put the solution under UV light for 3h to reduce AgNO 3 , after the reaction is finished, wait until it drops to room temperature...

Embodiment 2

[0033] By the steps in Example 1, the difference is (2) the g-C of 0.20g 3 N 4 nanosheets and 0.005g AgNO 3 Dissolve in 50ml deionized water and stir; then put the solution under UV light for 3h to reduce AgNO 3 , after the reaction is finished, wait until it drops to room temperature, wash the solid product with deionized water and ethanol, and dry to obtain Ag / g-C 3 N 4 composite photocatalyst.

[0034] Get the sample in (2) and carry out the photocatalytic degradation test in the photochemical reaction instrument, record this photocatalyst to concentration of 0.1g to be 20mg L -1 The degradation rate of tetracycline reached 21.35% within 120min.

Embodiment 3

[0036] By the steps in Example 1, the difference is (2) the g-C of 0.20g 3 N 4 nanosheets and 0.01g AgNO 3 Dissolve in 50ml deionized water and stir; then put the solution under UV light for 3h to reduce AgNO 3 , after the reaction is finished, wait until it drops to room temperature, wash the solid product with deionized water and ethanol, and dry to obtain Ag / g-C 3 N 4 composite photocatalyst.

[0037] Get the sample in (2) and carry out the photocatalytic degradation test in the photochemical reaction instrument, record this photocatalyst to concentration of 0.1g to be 20mg L -1 The degradation rate of tetracycline reached 27.42% within 120min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com