Novel sp3 carbon material and high-pressure preparation method thereof

A carbon material, a new technology, applied in the field of sp3 carbon material preparation, to achieve the effect of simple and safe preparation process, good sample crystallinity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

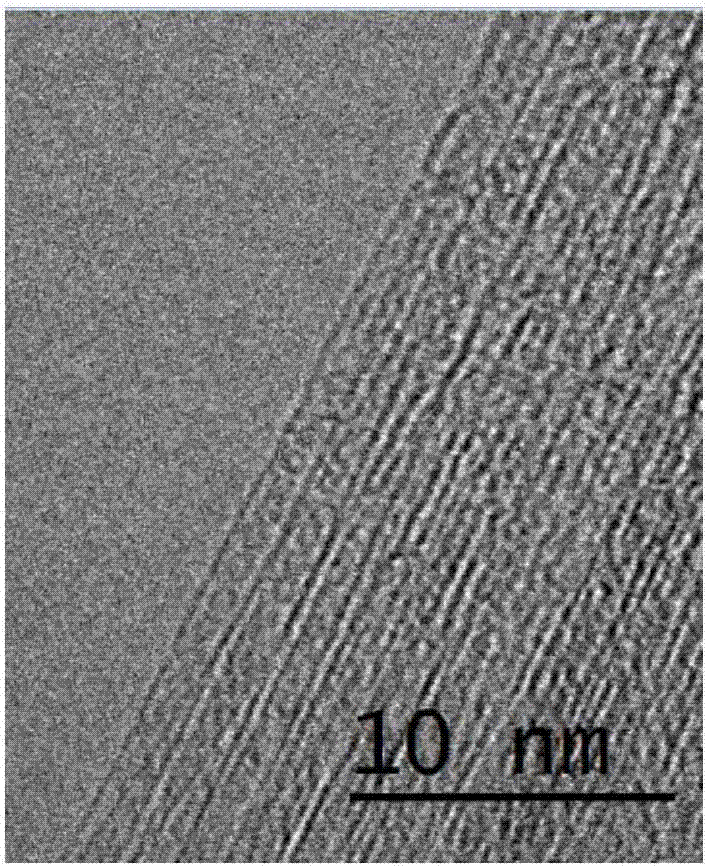

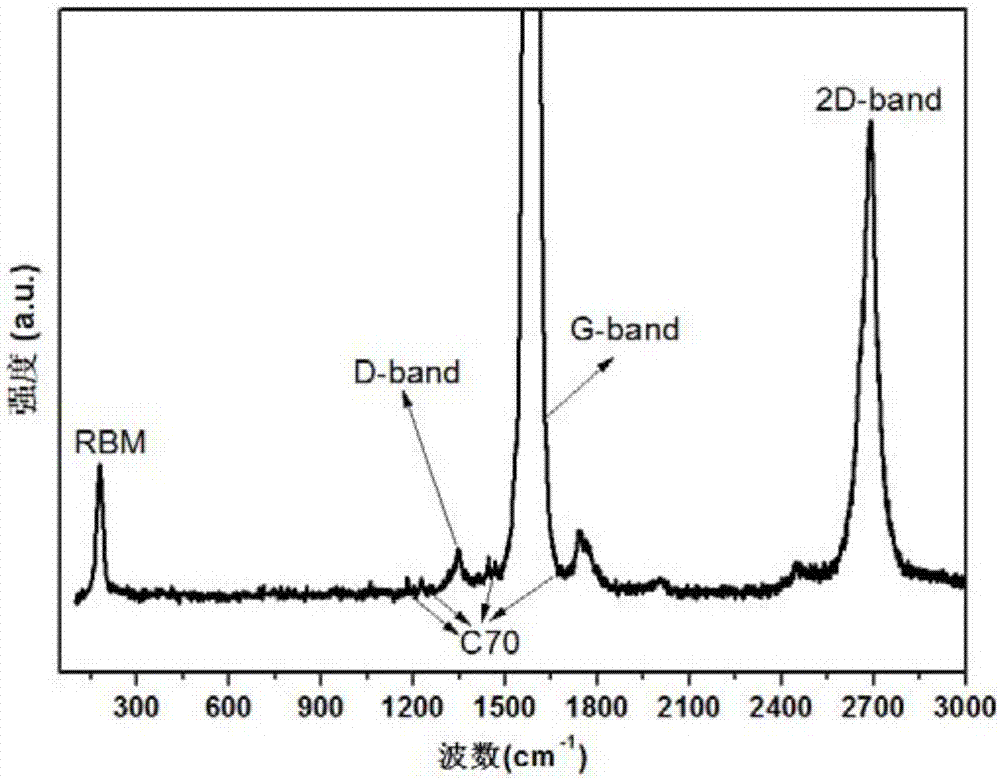

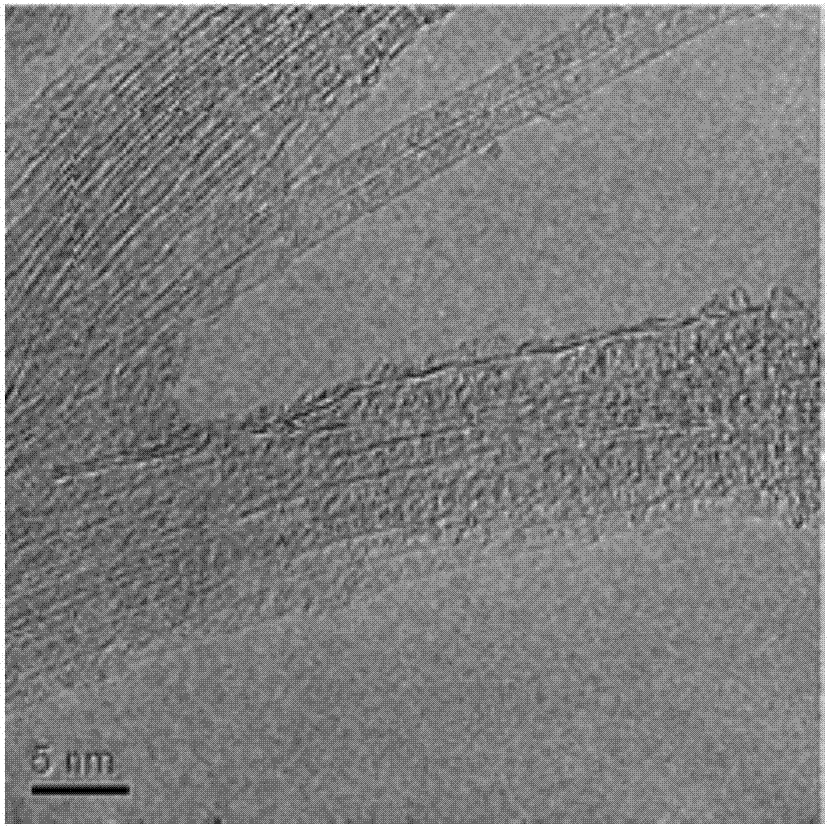

[0033] A diamond anvil with an anvil surface of 200 μm was used to prepress a metal rhenium sheet, and a small hole with a diameter of 60 μm was drilled in the center of the indentation as a sample cavity. Will C 70 The @SWNTs sample fills the sample cavity, uses diamond as a pressure calibration substance, and adopts a hard pressing method without adding any pressure transmission medium for pressurization. When the pressure rises to 70GPa, the pressure is released to normal pressure, and a new carbon material with superhard properties is obtained, and the hardness reaches 90GPa in Vickers hardness. The electron micrographs and X-ray diffraction spectra of the new carbon materials are shown in Figure 5 and Image 6 .

Embodiment 2

[0035] Raw material, press and sample cavity are the same as embodiment 1. Will C 70 The @SWNTs sample fills the sample cavity, uses diamond as a pressure calibration substance, and adopts a hard pressing method without adding any pressure transmission medium for pressurization. When the pressure rises to 60GPa, the pressure is released to normal pressure, and a new carbon material with superhard properties is obtained. The X-ray diffraction spectrum of the new carbon material obtained is shown in Figure 7 .

[0036] Conclusion: When the pressure reaches 60GPa, the new superhard carbon material can still be obtained after the pressure is released.

Embodiment 3

[0038] Raw material, press and sample cavity are the same as embodiment 1. Will C 70 The @SWNTs sample fills the sample cavity, uses diamond as a pressure calibration substance, and adopts a hard pressing method without adding any pressure transmission medium for pressurization. When the pressure was raised to 50GPa, the pressure was released to normal pressure, and the X-ray diffraction spectrum of the product obtained was shown in Figure 8 .

[0039] Conclusion: When the pressure reaches 50GPa, the X-ray diffraction peak of the unloaded sample is the signal of the raw material carbon nanotubes, and a new type of carbon material with superhard properties cannot be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com