Method for recovery and reuse of polyurethane material

A polyurethane material and polyurethane technology, applied in the field of recycling of industrial solid waste materials, can solve the problems that the economic value of waste polyurethane materials cannot be fully utilized, the types/sources of polyurethane materials that can be processed are few, and the capacity of polyurethane materials needs to be improved, so as to reduce production Cost and resource consumption, good industrial prospects, and the effect of improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

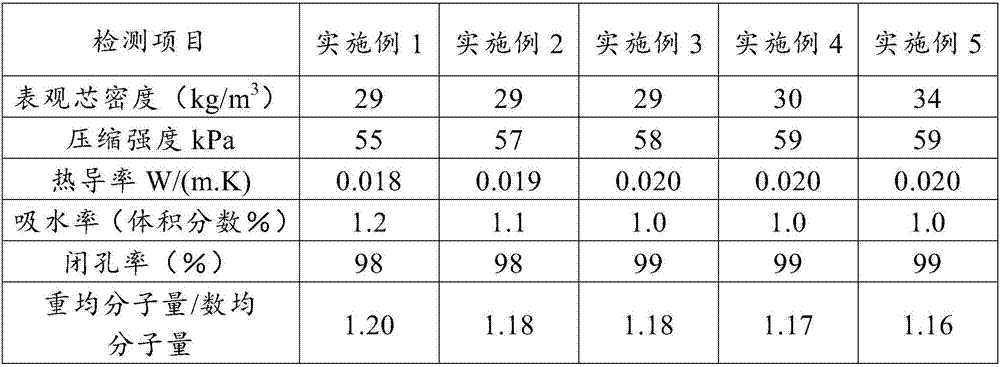

Examples

Embodiment 1

[0030] Example 1: Treatment of Polyurethane Foam Polyurethane Material

[0031] Clean the surface of 30kg of waste polyurethane foam to remove inorganic impurities on the surface, and cut it into small pieces with a length less than 300mm.

[0032] A small piece of polyurethane foam was thrown into the reactor. Reactor volume is 0.1m 3 , with a heating jacket, heated by heat conduction oil, with a built-in stirring device. The reaction kettle was heated by heat conduction oil, and the temperature was controlled at 180° C., and the polyurethane foam was heated and dried for 25 minutes. The water content of the dried polyurethane foam was measured to be 0.5 wt%.

[0033] Add 10kg of 1,4-butanediol, 5kg of 1,4-cyclohexanediol, 0.1kg of lithium carbonate, 0.2kg of strontium carbonate and 0.05kg of octylated diphenylamine to the reactor, stir well, and keep the temperature in the reactor 180°C, reacted for 7 hours, cooled to 50°C, and discharged to obtain a light brown alcoholys...

Embodiment 2

[0034] Embodiment 2: the processing of the polyurethane material of the industrial scrap of polyurethane blanking diaphragm

[0035] Clean the surface of 30kg of industrial scraps of polyurethane punched diaphragms to remove inorganic impurities on the surface, and cut them into small pieces with a length of less than 300mm.

[0036] Put the industrial leftovers of small pieces of polyurethane punched diaphragms into the reactor. Reactor volume is 0.1m 3 , with a heating jacket, heated by heat conduction oil, with a built-in stirring device. The reaction kettle was heated by heat conduction oil, and the temperature was controlled at 190°C. The industrial scraps of polyurethane punched diaphragms were heated and dried for 20 minutes, and the industrial scraps of polyurethane punched diaphragms after drying were measured. The amount of water is 0.5 wt%.

[0037] Add 2-methylpropanediol 20kg, 2,2,4-trimethyl-1,3-pentanediol 10kg, lithium carbonate 0.2kg, strontium carbonate 0....

Embodiment 3

[0038] Embodiment 3: the processing of spandex yarn industrial waste polyurethane material

[0039] Clean the surface of 25kg spandex industrial waste to remove inorganic impurities on the surface, and cut it into small sections with a length less than 300mm.

[0040] Throw small pieces of spandex industrial waste into the reactor. Reactor volume is 0.1m 3 , with a heating jacket, heated by heat conduction oil, with a built-in stirring device. The reaction kettle was heated by heat-conducting oil, and the temperature was controlled at 190° C., and the spandex industrial waste was heated and dried for 20 minutes. The moisture content of the dried spandex industrial waste was measured to be 0.5 wt%.

[0041]Add 2-methylpropanediol 35kg, 2,2,4-trimethyl-1,3-pentanediol 10kg, lithium carbonate 0.1kg, strontium carbonate 0.25kg, N-methylmorpholine 0.01kg and 0.05kg of octylated diphenylamine, fully stirred, keeping the temperature in the reactor at 190°C, reacted for 6 hours, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com