Semi-conductive shielding material for 10-220kV electric cable and preparation method

A shielding material and semi-conductive technology, applied in the direction of power cables with shielding/conducting layers, etc., can solve the problems of affecting the electric field homogenization effect of cable products, hindering the connection of conductive carbon black, reducing the formation of conductive networks, etc., to improve the uniformity. The effect of chemical electric field, easy to recycle and reuse, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

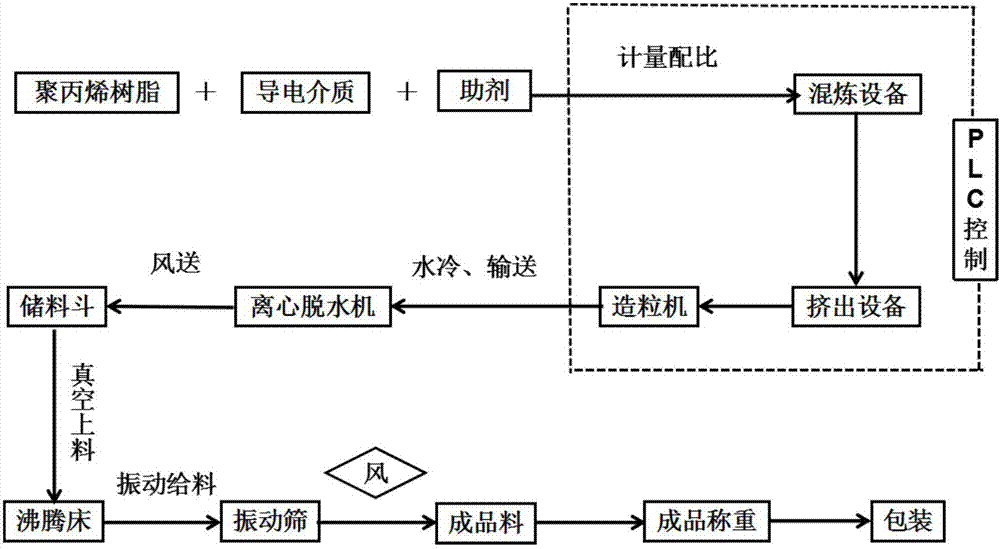

Method used

Image

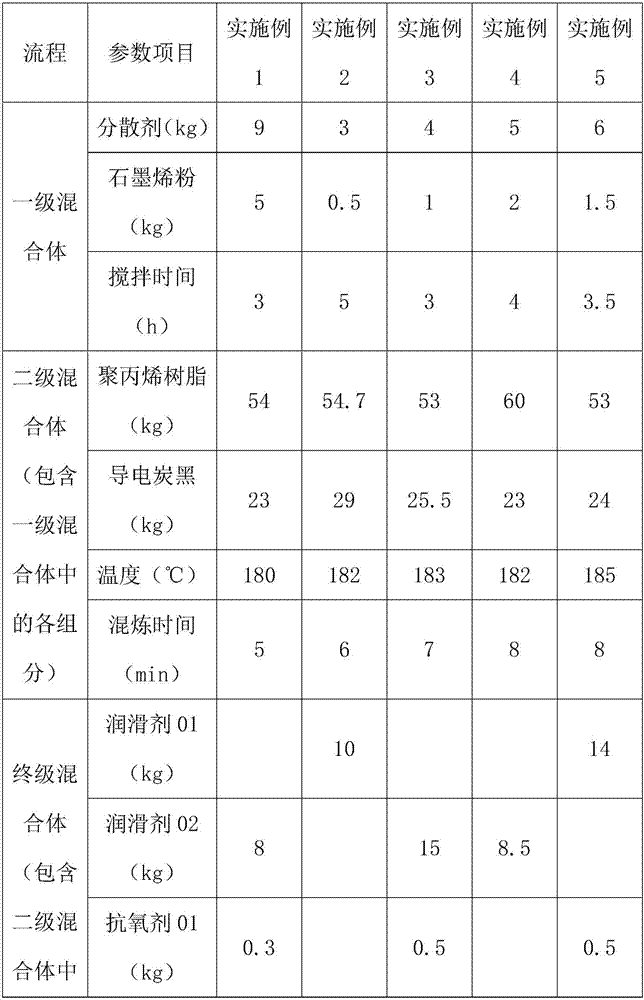

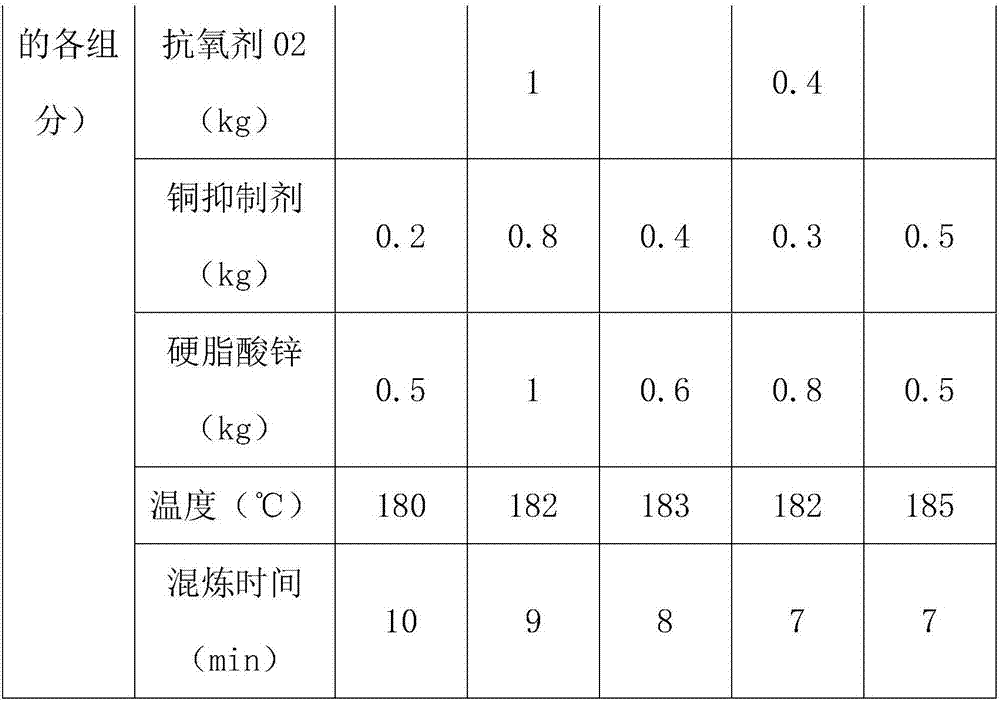

Examples

Embodiment Construction

[0037] The semiconductive shielding material used for 10-220kV high-voltage electric wire of the present invention is a semiconductive shielding material composed of non-crosslinked polypropylene resin as a base material and conductive carbon black as a conductive medium.

[0038] As a preferred solution, the conductive medium is a mixed material of conductive carbon black and graphene.

[0039] Polypropylene is a non-toxic, odorless and tasteless non-polar material with a density of 0.91g / cm 3 , is currently one of the lightest varieties of all plastics. When non-crosslinked, it also has excellent mechanical properties and chemical resistance such as high strength, high hardness, wear resistance, and bending fatigue resistance. It also has excellent resistance to moisture absorption, with a water absorption rate of only 0.01% in water. Polypropylene has good heat resistance, and its products can be sterilized at a temperature above 100°C. Under the condition of no external ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com