Yellow phosphor, preparation method thereof and application thereof in light-emitting devices

A technology of yellow phosphors and light-emitting devices, applied in the directions of light-emitting materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of unfavorable warm white LED output, high color temperature of white LED output, and achieve integrated and integrated design, High production efficiency and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

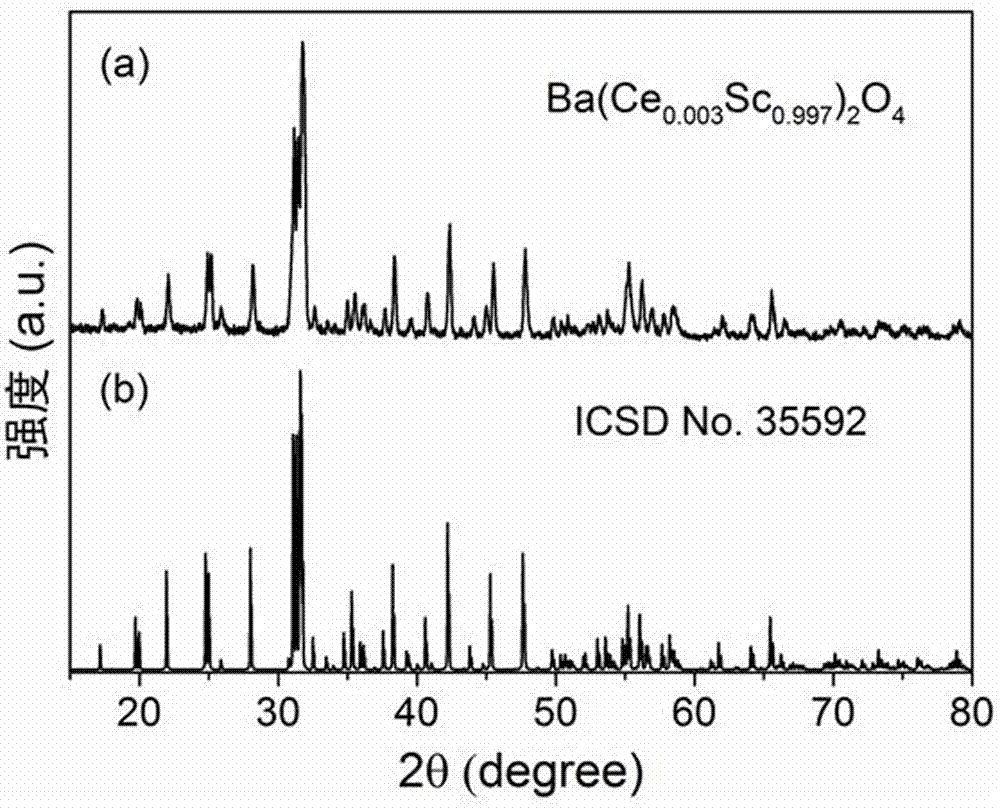

[0039] One (Ce 0.003 Sc 0.997 ) 2 O 4 Yellow phosphor, the preparation method steps are as follows:

[0040] 1) Based on BaO, Sc 2 O 3 And Ce(NO 3 ) 3 As the initial raw material, it is formulated according to the molar ratio of Ba:Ce:Sc of 1:0.04:1.96, and is dry-mixed for 5 h by planetary ball mill and ground to obtain a powder with uniform particle size distribution;

[0041] 2) Press the mixed powder in step 1) into a cylindrical shape at 40 MPa, put it in a platinum crucible, heat it up to 1300°C at 2~5°C / min, burn it in air at 1300°C for 5 hours, then Reduce to room temperature at 2~5°C / min and grind to obtain as-fired block powder with an average particle size of 0.5~15μm;

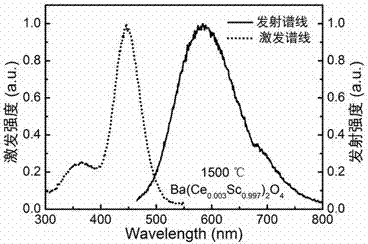

[0042] 3) Press the as-fired block powder of step 2) again under 40 MPa into a block, put it in a platinum crucible, and in a reducing atmosphere of CO / Ar (volume ratio 5:90) at 2~5℃ The temperature is increased to 1500℃ for 5 h after the second sintering, and the corresponding block powder is obtained. A...

Embodiment 2

[0044] A kind of Ba(Ce 0.003 Sc 0.997 ) 2 O 4 Yellow phosphor, the preparation method steps are as follows:

[0045] 1) Take BaCO 3 , Sc 2 O 3 And CeO 2 As the initial raw material, the molar ratio of Ba:Ce:Sc is 1:0.006:1.994. The mixture is wet-mixed with an alcohol solution for 1 h, then dried in a fume hood at room temperature and ground to obtain a powder with uniform particle size distribution;

[0046] 2) Press the mixed powder in step 1) into a cylindrical shape at 40 MPa, put it in a corundum crucible, heat it up to 1300°C at 2~5°C / min, and burn it in air at 1300°C for 5 hours, then Reduce to room temperature at 2~5°C / min and grind to obtain as-fired block powder with an average particle size of 0.5~15μm;

[0047] 3) The as-fired block powder of step 2) is pressed again at 40 MPa into a block, put into the corundum crucible, in H 2 / N 2 (Volume ratio is 5:95) In a reducing atmosphere, the temperature is increased to 1500℃ for 5 h at 2~5℃ / min to obtain the corresponding bulk ...

Embodiment 3

[0051] A kind of Ba(Ce 0.003 Sc 0.997 ) 2 O 4 Yellow phosphor, the preparation method steps are as follows:

[0052] 1) Take BaCO 3 , Sc 2 O 3 And CeO 2 As the initial raw material, the molar ratio of Ba:Ce:Sc is 1:0.006:1.994. The mixture is wet-mixed with an alcohol solution for 1 h, then dried in a fume hood at room temperature and ground to obtain a powder with uniform particle size distribution;

[0053] 2) Press the mixed powder in step 1) into a block under 40 MPa, put it in a corundum crucible, heat it up to 1300℃ at 2~5℃ / min, first burn it in air at 1300℃ for 5 hours, and then 2~5℃ / min down to room temperature and grinding to obtain as-fired block powder with average particle size of 0.5~15μm;

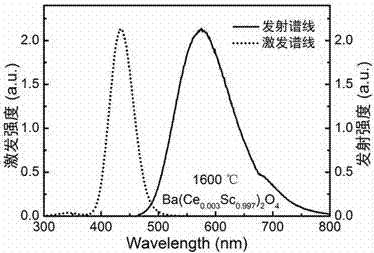

[0054] 3) Press the as-fired block powder of step 2) into a cylindrical shape again under 40 MPa, put it in a corundum crucible, 2 / N 2 (Volume ratio is 5:95) In a reducing atmosphere, the temperature is increased to 1600℃ for 5 h at 2~5℃ / min to obtain the corresponding bulk powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com