Preparation method for quartz crucible with ultra-pure coating

A production method and technology of quartz crucibles, which are applied in the field of production of ultra-high-purity coated quartz crucibles, can solve problems such as low carrier life of crystal ingots, high impurity content, and ultra-high-purity quartz sand that does not meet production requirements, so as to achieve the improvement of silicon Ingot quality and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] A method for making an ultra-high-purity coated quartz crucible, comprising the following steps:

[0022] (1) Select ultra-high-purity quartz sand with a particle size of 0.2mm-0.6mm (purity ≥ 99.9999%), add deionized water with a weight of 10%-40% of the ultra-high-purity quartz sand, and put it into a ball mill for ball milling until the slurry particle size is 6μm-15μm, made into slurry. The ultra-high-purity quartz sand with a particle size of 0.2mm-0.6mm is composed of particles with different particle sizes as follows: 10%-35% of particles with a particle size greater than 500 μm, 50%-70% of particles with a particle size of 300-500 μm, 10%-35% of the particle size is less than 300μm.

[0023] (2) The slurry prepared in step (1), ultra-high-purity quartz sand and silica sol with a particle size of 0.15mm-0.05mm are mixed according to the ratio of weight ratio=(1-4):(1-3):1, fully After stirring for 0.5-2 hours, an ultra-high-purity slurry is made. The ultra-hig...

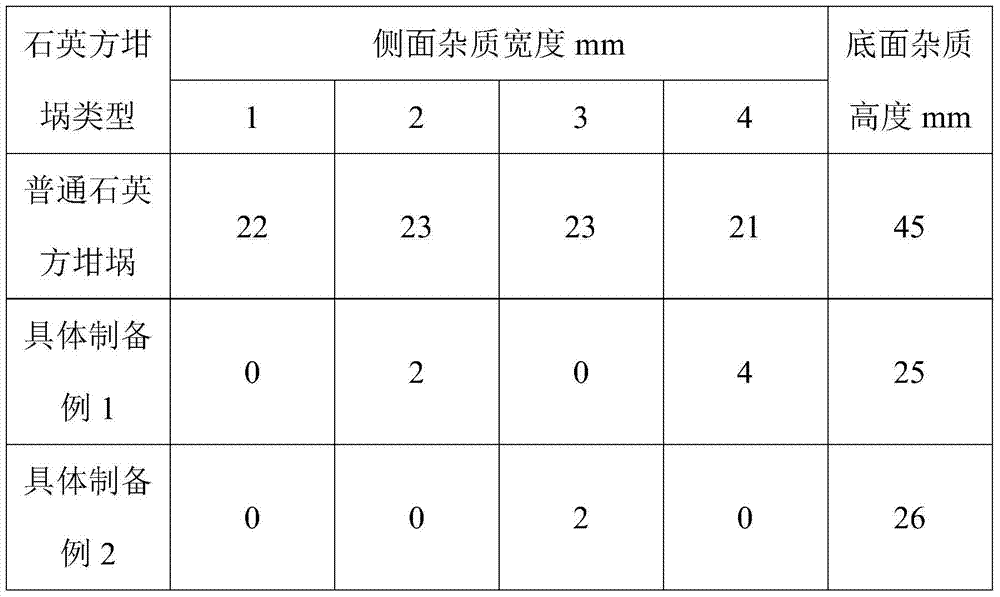

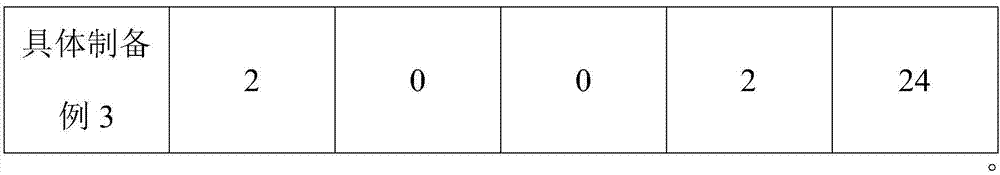

specific preparation example 1

[0027] A method for making an ultra-high-purity coated quartz crucible, comprising the following steps:

[0028] (1) 10kg of ultra-high-purity quartz sand (its particle size by weight percentage is composed of: 20% greater than 500 μm, 50% of 300 μm-500 μm, and 30% less than 300 μm) 10kg, add 2kg of deionized water, put In a ball mill barrel with a capacity of 20L, ball mill for 5 hours, and the particle size of the slurry after ball milling is in the range of 6 μm-15 μm.

[0029] (2) 400g of ball-milled slurry, ultra-high-purity quartz sand (25% greater than 106 μm, 40% of 106 μm-75 μm, 35% less than 75 μm) 300g, silica sol (commercially available, solid content 25%) 100g After mixing and fully stirring for 2 hours, an ultra-high-purity slurry is made.

[0030] (3) Coat the inner surface of the square quartz crucible with the ultra-high-purity slurry prepared in step (2) by spraying. Dry in the furnace for 2 hours to obtain an ultra-high-purity coated quartz crucible. Afte...

specific preparation example 2

[0032] A method for making an ultra-high-purity coated quartz crucible, comprising the following steps:

[0033] (1) 10kg of ultra-high-purity quartz sand (its particle size by weight percentage is composed of: 10% greater than 500 μm, 70% of 300 μm-500 μm, 20% less than 300 μm) 10kg, add 2kg of deionized water, put In a ball mill barrel with a capacity of 20L, ball mill for 3.5 hours, and the particle size of the slurry after ball milling is in the range of 6 μm-15 μm.

[0034] (2) 100g of slurry after ball milling, 100g of ultra-high-purity quartz sand (50% greater than 106 μm, 30% of 106 μm-75 μm, 20% less than 75 μm), 100 g of silica sol, and fully stirred for 0.5 hours, prepared into ultra-high-purity slurry.

[0035] (3) Apply the ultra-high-purity slurry prepared in step (2) to the inner surface of the square quartz crucible by brushing, the coating thickness is 0.3mm, and after natural drying at room temperature for 1 hour, place it in a room with a temperature of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com