Material growth device, growth method and detection device using gas phase transport

A gas phase transmission and growth device technology, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of uneven growth thickness, lack of growth technology, device performance and reliability decline, and achieve doping concentration The effect of optimization, simplification of the production process, and easy growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

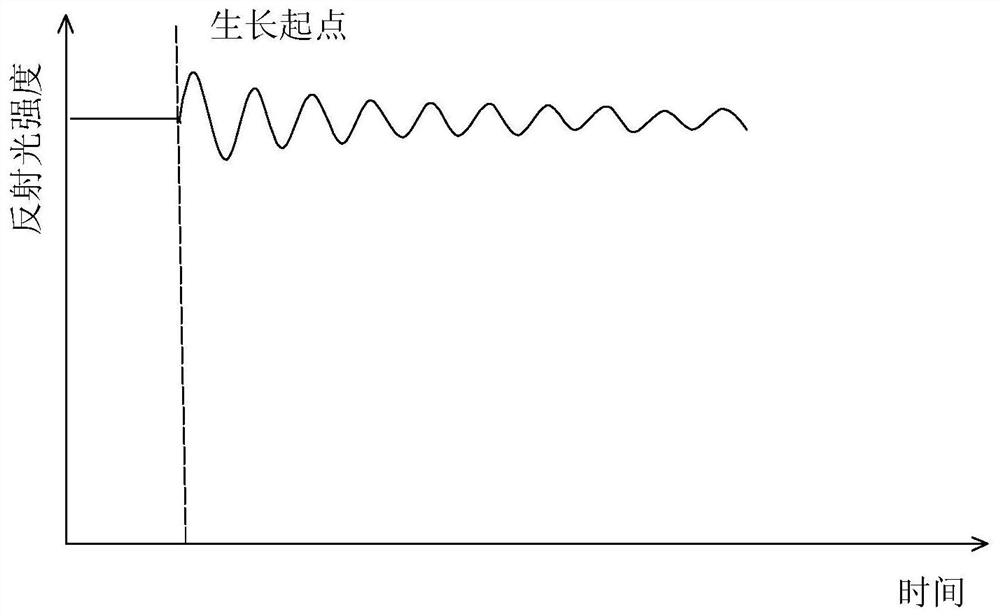

[0050] Example 1: Growth of quasi-intrinsic SiC epitaxial film

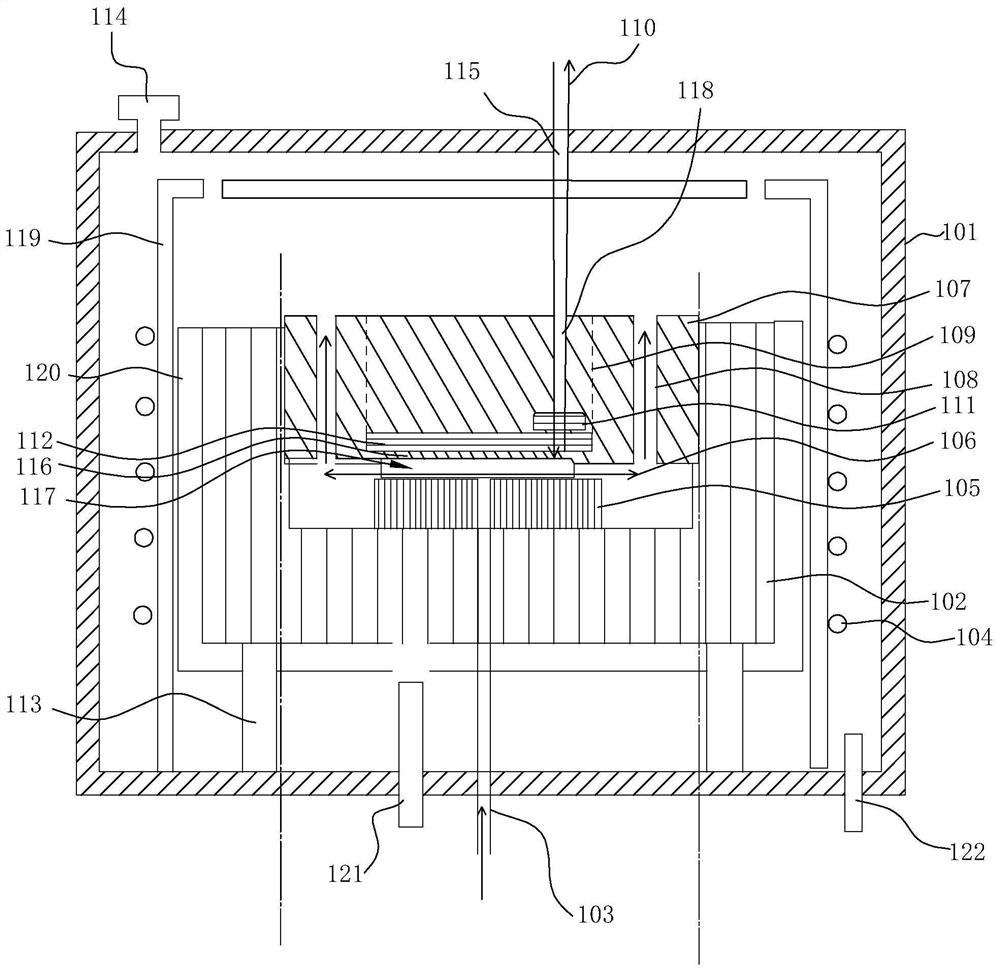

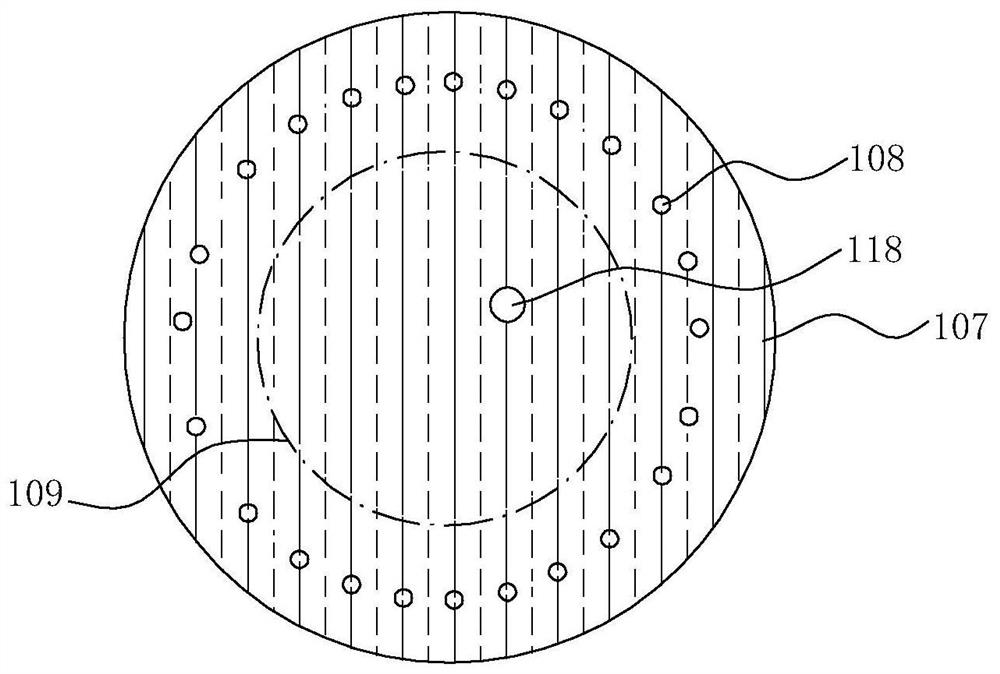

[0051] Using an induction heated growth system using vapor transport, Figure 5 is its cross-section:

[0052] 1) Growth device: the metal vacuum chamber 401 is made of stainless steel; its wall can be fed with cooling water; The internal volume is: diameter φ80cm x 80cm.

[0053]Use 4 insulating, relatively heat-insulating alumina ceramic rods (bottom) and molybdenum tubes (upper) to make the support 412, a total of 15cm, diameter φ3cm, the entire growth chamber 402 is fixed on the bottom surface of the vacuum chamber 401. And between the water-cooled induction heating device 404 (ie high-frequency coil) and the growth chamber 402, a quartz tube 416 and a graphite foam 417 with holes (~2cm thick) are added. The former plays the role of insulation, and the latter plays the role of heat insulation. Many 0.5mm drill holes are deliberately formed in the graphite foam 417 to facilitate the overflow of impurity ...

example 2

[0060] Example 2: Growth of multilayer structure SiC epitaxial film

[0061] Using a growth system using vapor transport, induction heating, Figure 5 is its cross section.

[0062] Growth device: the metal vacuum chamber 401 is made of stainless steel; its wall can be fed with cooling water; and a vacuum pump interface 413 and a light entrance 414 are cut. The internal volume is: diameter φ80cm x 80cm.

[0063] Using 4 insulating, relatively heat-insulating alumina ceramic rods (lower part) and molybdenum tubes (upper part) 412, a total of 15 cm, diameter φ3 cm, the entire growth chamber 402 is fixed on the bottom surface of the vacuum chamber 401. And between the water-cooled induction heating device (ie high-frequency coil) 404 and the growth chamber 402, a quartz tube 416 and a graphite foam 417 with holes (~2cm thick) are added. The former plays the role of insulation, and the latter plays the role of heat insulation. Many 0.5mm drill holes are deliberately formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com