Efficient and lasting antibacterial material and preparation method thereof

An antibacterial material and long-lasting technology, applied in the field of high-efficiency and durable antibacterial materials and their preparation, can solve the problems of weak binding between antibacterial materials and carbon fiber cloth, decreased antibacterial performance, and weak binding between antibacterial nanomaterials and inorganic carriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

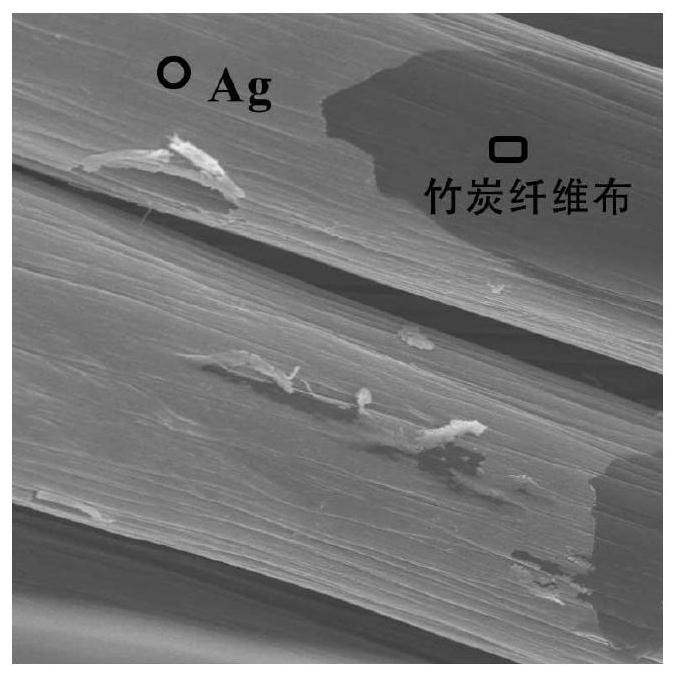

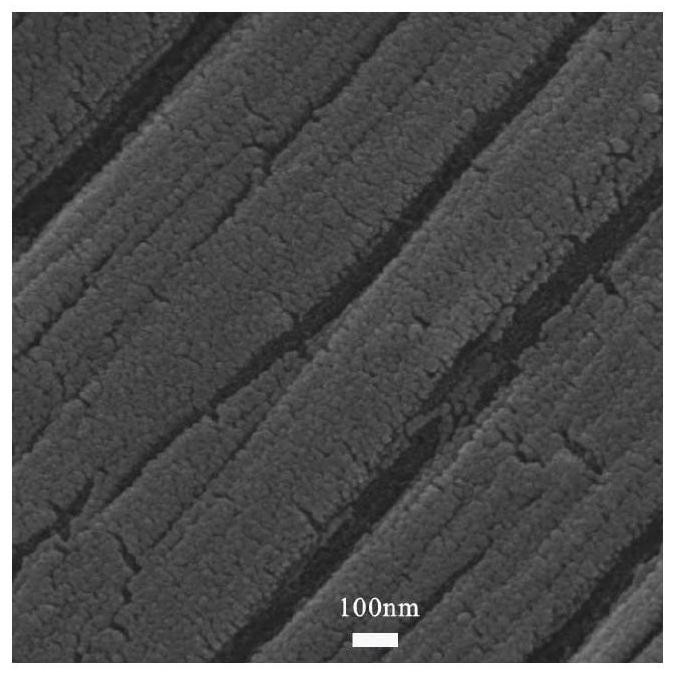

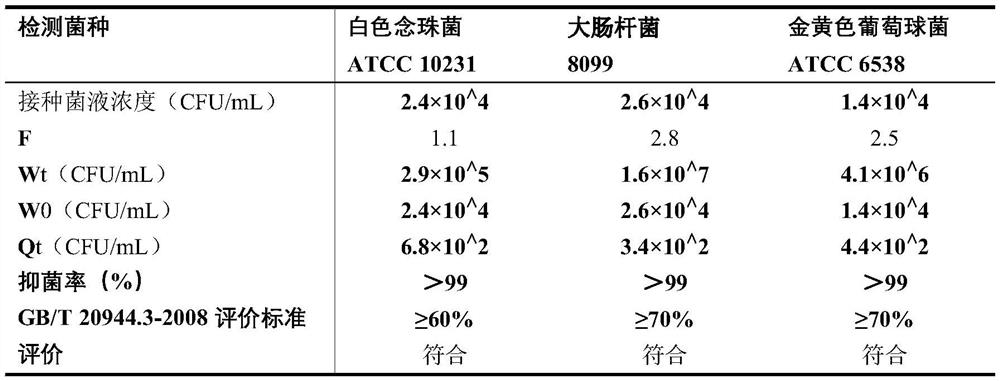

Embodiment 1

[0021] The preparation method of high-efficiency and durable antibacterial materials, the specific steps are as follows: a. Soak the bamboo charcoal fiber cloth in acetone, ethanol, and deionized water for 30 minutes respectively; then arrange the bamboo charcoal fiber in a constant temperature drying box and dry it at 60 ° C Standby; b. arrange the bamboo charcoal fiber under the dielectric barrier discharge equipment and process it for 30min, then put it into the thermal evaporation film cabin and fix it, put the Ag particles in the evaporation boat of the thermal evaporation film machine, and vacuum to 10 -3 Pa, set the current to control the evaporation rate as The time is 6min, and a layer of Ag nanoparticles is plated on the surface of the bamboo charcoal fiber cloth, with an average particle size of 4nm; c. 1mg polyvinylpyrrolidone, 10ml ethylene glycol and 0.1mg succinic acid are dissolved in 20ml deionized water in turn, and stirred for 60min , to form solution A, th...

Embodiment 2

[0023] The preparation method of high-efficiency and durable antibacterial materials, the specific steps are as follows: a. Soak the bamboo charcoal fiber cloth in acetone, ethanol, and deionized water for 30 minutes respectively; then arrange the bamboo charcoal fiber in a constant temperature drying box and dry it at 60 ° C Standby; b. arrange the bamboo charcoal fiber under the dielectric barrier discharge equipment and process it for 30min, then put it into the thermal evaporation film cabin and fix it, put the Ag particles in the evaporation boat of the thermal evaporation film machine, and vacuum to 10 -3 Pa, set the current to control the evaporation rate as The time is 6min, and the surface of the bamboo charcoal fiber cloth is plated with a layer of Ag nano crystal seeds, the average particle size is 4nm; c. 0.5mg polyvinylpyrrolidone, 5ml ethylene glycol and 0.05mg succinic acid are dissolved in 20ml deionized water successively, Stir for 60min to form solution A, th...

Embodiment 3

[0034] The difference between this embodiment and embodiment 2 is that the soaking ultrasonic time of step a is changed to 5, 60min, others are the same as embodiment 2, specifically as follows: a. the bamboo charcoal fiber cloth is placed in acetone, ethanol, deionized water successively to soak respectively Ultrasound for 5 and 60 minutes; then arrange the bamboo charcoal fibers in a constant temperature drying box, and dry them at 60°C for later use; b. Arrange the bamboo charcoal fibers under dielectric barrier discharge equipment for 30 minutes, and then put them into the thermal evaporation film cabin for fixation , put the Ag particles into the evaporation boat of the thermal evaporation film machine, and evacuate to 10 -3 Pa, set the current to control the evaporation rate as The time is 6min, and the surface of the bamboo charcoal fiber cloth is plated with a layer of Ag nano crystal seeds, the average particle size is 4nm; c. 0.5mg polyvinylpyrrolidone, 5ml ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com